Ama-PCB aguquguqukayo aqinile(Amabhodi wesekethe aphrintiwe aqinile) athola ukuduma kumishini kagesi ngenxa yesakhiwo sawo esiyingqayizivele esihlinzeka kokubili ukuguquguquka nokuqina.Le nhlanganisela ivumela ukuguquguquka okukhulu komklamo nokuqina, okuyenza ifaneleke ezinhlobonhlobo zezinhlelo zokusebenza. Kodwa-ke, ngaphambi kokusebenzisa lawa mabhodi emikhiqizweni ye-elekthronikhi, ukuqina kwawo kufanele kuqondwe.Kulesi sihloko, sibheka izici ezithinta ukuqina kwamabhodi e-PCB aguquguqukayo aqinile nokuthi yini ongayenza ukuze uqinisekise impilo yabo ende.

Ikhwalithi yezinto ezibonakalayo kanye Nokukhethwa kuma-PCB aqinile aguquguqukayo:

Ukukhethwa kwezinto ezisetshenziselwa ukwakha i-PCB eguquguqukayo eqinile kudlala indima ebalulekile ekunqumeni ukuqina kwayo kukonke.Izinto ezisezingeni eliphakeme njenge-polyimide noma ama-substrates akhethekile afana ne-FR-4 asetshenziswa kabanzi ngenxa yezakhiwo zawo ezinhle kakhulu zemishini nezikagesi. Lezi zinto zinokumelana okuhle kakhulu nokugoba, ukuguquguquka, umswakama kanye noshintsho lokushisa oludingekayo ezinhlelweni eziningi.

I-Polyimide, into evamile engaphansi kwe-substrate kuma-PCB aguquguqukayo, inokuqina okuhle kakhulu kokushisa, okuvumela ibhodi ukuthi likwazi ukumelana nezinga lokushisa eliphezulu ngaphandle kokuyekethisa ubuqotho bayo.Lesi sici sibaluleke kakhulu ezintweni ze-elekthronikhi okungenzeka zibe ngaphansi kwamazinga okushisa aphezulu okusebenza noma izimo zemvelo ezimbi kakhulu.

Ngaphezu kwalokho,I-polyimide ine-coefficient ephansi yokunwetshwa kokushisa, okusho ukuthi iyakhula futhi ifinyele kancane ngokushintsha kwezinga lokushisa.Lesi sici siqinisekisa ukuthi i-PCB eguquguqukayo eqinile igcina ukuqina kwayo kobukhulu futhi ivimbela noma yimuphi umonakalo ongaba khona noma ukwehluleka ngenxa yengcindezi yokushisa.

Ama-substrates akhethekile afana ne-FR-4 nawo asetshenziswa kabanzi ezakhiweni eziguquguqukayo eziqinile ngenxa yezakhiwo zazo ezinhle kakhulu zemishini nezikagesi.I-FR-4 iyimpahla ebambezela ilangabi enokufakwa kahle kukagesi namandla aphezulu okusebenza. Iyaziwa ngokuzinza kwayo kobukhulu, ukumelana nomswakama kanye nekhono lokumelana namazinga okushisa aphezulu.

Amabhodi ama-Rigid-flex enziwe ngezinto ezisezingeni eliphezulu, okuqinisekisa ukuthi angakwazi ukumelana nobunzima bokusetshenziswa kwansuku zonke kanye nezimo zemvelo. Ukuqina kwe-PCB kubalulekile ekusebenzeni kwayo nasekuphileni isikhathi eside, ikakhulukazi ezinhlelweni lapho igotshwa futhi igotshwa ngokuphindaphindiwe.

Ngaphezu kwekhwalithi yezinto ezibonakalayo, ukukhetha impahla efanele yemfuneko ethile yedizayini nakho kubalulekile.Ukukhethwa kwezinto kuncike ezicini ezifana nebanga lokushisa elisebenzayo, ukuguquguquka nezimfuneko zokucindezelwa kwemishini, kanye nokuchayeka komswakamo nokuchayeka kwamakhemikhali i-PCB engahlangabezana nakho. Abakhiqizi bahlola ngokucophelela lezi zici futhi bakhethe izinto ezihlangabezana nalezi zidingo, baqinisekise ukuqina kwama-PCB aguquguqukayo aqinile ezinhlelweni zabo ezihlosiwe.

Ukuvumelana nezimo kanye ne-Bend Radius:

I-Flex ne-bend radius yizinto ezibalulekile zokucatshangelwa ekwakhiweni nasekukhiqizeni i-PCB eguquguqukayo eqinile. Lawa ma-PCB aziwa ngokukwazi kwawo ukugoba ngaphandle kokudala umonakalo noma ukwehluleka, okuwenza afanelekele izinhlelo zokusebenza ezidinga ukuguquguquka nokuqina.

I-Bend radius iyibanga elincane kakhulu ibhodi elingagotshwa ngaphandle kokulimaza izingxenye zalo noma ukusebenza kukonke.Kunqunywa izici ezimbalwa, okuhlanganisa izakhiwo ezibonakalayo ze-PCB, ukwakheka nokuklanywa kwezingxenye, kanye nokuma kwemikhondo kanye ne-vias. Idizayini efanele yendawo yokugoba ibalulekile ukuvimbela ukuqhekeka noma ukuklebhuka ngesikhathi sokukhiqiza. Lokhu kuhilela ukuqinisekisa ukuthi ibhodi lilingana nosayizi futhi libekwe ukuze livumelane nokuguquguquka okulindelekile noma ukugoba ngaphandle kokuphazamisa ubuqotho bengxenye. Futhi, ukusebenzisa i-copper trace reinforcement endaweni yokugoba kusiza ukwandisa ukuqina kwebhodi nokuvimbela umonakalo. Ukwenziwa okungaguquguquki nezindlela zokuhlanganisa ezinembile zibalulekile ekugcineni ukuguquguquka kwama-PCB aqinile-flex ngisho nangemva kwemijikelezo eminingi yokugoba. Lokhu kuhlanganisa ukunaka imininingwane ekuthengiseni, ukubekwa kwezingxenye kanye nokubambelela kumazinga emboni kanye nezindlela ezihamba phambili.

Kubalulekile ukuqaphela ukuthi ukuqina kwamabhodi aqinile-flex kungase kuhluke kuye ngokuthi isicelo esithile.Izimboni ezifana ne-aerospace noma ezokwelashwa ngokuvamile zidinga ukuguquguquka okuqhubekayo noma okwedlulele futhi zingadinga ukucatshangelwa kwedizayini okuqinile ukuze kuqinisekiswe ukwethembeka nokuqina kwesikhathi eside. Ezimweni ezinjalo, izinyathelo ezengeziwe zingathathwa, njengokwengeza ukuqinisa okwengeziwe ezindaweni ezibucayi noma ukukhetha izinto ezinezici zokugoba ezithuthukisiwe.

Izici Zemvelo:

Ukuqina kwebhodi eliguquguqukayo eliqinile kuthonywa kakhulu amandla ayo okumelana nezinto ezizungezile ezifana nokushintsha kwezinga lokushisa, umswakama, nokudlidliza—zonke izimo ezivamile zemishini kagesi.

Ukuhamba ngebhayisikili izinga lokushisa ukuhlola okujwayelekile kokwethembeka okwenziwa kuma-PCB aguquguqukayo ukuze kuhlolwe ukumelana kwawo nokwehla kwezinga lokushisa okudlulele.Ngalezi zivivinyo, abakhiqizi bangakwazi ukubona ubuthakathaka obungaba khona ekwakhiweni kwebhodi noma ukukhetha izinto ezingase ziholele ekuhlulekeni ngaphansi kwezimo ezithile zokushisa.

Umswakamo ungaphinda uthinte ukuqina kwamabhodi aguquguqukayo. Ukuze kuthuthukiswe ukumelana kwabo, abakhiqizi bavame ukusebenzisa i-coatings ekhethekile noma i-conformal coatings ehlinzeka ngesendlalelo esengeziwe sokuvikela.Lezi zembatho zivimbela ukungena komswakama futhi zivikele i-PCB ekugqwaleni, inwebe impilo yayo yonke.

Esinye isici esibalulekile semvelo esithinta ukuqina kwe-rigid-flex ukudlidliza.Ukudlidliza kungacindezela ngokuzenzakalelayo ibhodi nezingxenye zalo, kubangele ukwehluleka kwamalungu e-solder noma ukuhlukaniswa kwengxenye. Ukunciphisa imithelela yokudlidliza, abakhiqizi bangasebenzisa amasu afana nezimbambo, izinto ezinamathelayo noma okokukhweza kwemishini ukuze kuvikeleke izingxenye kanye nokunciphisa imiphumela yokudlidliza.

Ukwengeza, uthuli, ukungcola, nokunye ukungcola kungathinta ukusebenza nokuphila isikhathi eside kwamabhodi aqinile-flex.Uma lokhu kungcola kufakwe phezu kwebhodi lesifunda, kungase kubangele amasekhethi amafushane, ukugqwala noma ukuwohloka kwe-insulation. Ukubekwa uphawu nokuvikelwa okufanele kwamabhodi esifunda, kanye nokuhlanza nokugcinwa njalo, kubalulekile ekuvimbeleni lezi zinkinga.

Ukwengeza, i-electromagnetic interference (EMI) ingathinta ukusebenza kwamabhodi aqinile-flex, ikakhulukazi ezinhlelweni lapho izingxenye ezibucayi noma amasignali amaza aphezulu ekhona.Amasu okuvikela njengezindiza eziphansi noma izimbotshana ezivikelayo zisiza ukunciphisa i-EMI futhi ziqinisekise ubuqotho bokudluliswa kwesignali ebhodini.

Umthelela wamandla angaphandle (njengomthelela noma umthelela) kumaphaneli e-rigid-flex kumele nawo ucatshangelwe.Izisetshenziswa ezingaphansi kokuphathwa kabi noma ukuthuthwa zingase zibe sengozini yokulimala ngokomzimba. Ngakho-ke, ukupakishwa okufanele, izinto ezibamba ukushaqeka, nezivalo zokuvikela kubalulekile ekugcineni ukuqina kwebhodi.

Isakhiwo Sengxenye Nokulandelela:

Isakhiwo sengxenye kanye nokulandela umkhondo ebhodini eliguquguqukayo libalulekile ukuze kuqinisekiswe ukuqina kwalo.Isici esisodwa okufanele sicatshangelwe indawo eguqukayo yebhodi. Amabhodi e-Rigid-flex enzelwe ukugoba nokugoba, kodwa ukugoba ngokweqile ezindaweni ezithile kungabeka ukucindezeleka okungadingekile ezingxenyeni nasezintweni, okuholela ekuhlulekeni kwemishini. Ngokuhlela ngokucophelela izingxenye, abaklami banganciphisa ingozi yokucindezeleka kwemishini noma ukulimala.

Izingxenye kufanele zigcinwe kude nezindawo lapho ukugoba okunzima kwenzeka khona.Ukuwabeka ezindaweni eziqinile noma ezinzile ebhodini kungasiza ekuvikeleni ekucindezelekeni okungafuneki. Futhi, kubalulekile ukucabangela ubukhulu nesisindo sezingxenye. Izingxenye ezinkulu noma ezisindayo kufanele zibekwe ezindaweni okungenzeka ukuthi zingahlangabezana nokuguquguquka ngokweqile.

I-traces kanye ne-vias yizindlela ze-conductive ebhodini ezidinga ukubekwa ngamasu.Kufanele zibekwe ezindaweni lapho mancane amathuba okuba zibe ngaphansi kwengcindezi yokugoba. Ngokugwema izindawo zokugoba ezibucayi, unciphisa ingozi yokulimala komkhondo kanye nethuba lokuvula noma izikhindi.

Ukuze kuthuthukiswe ukuqina kwamaphaneli, ama-adhesive angasetshenziswa ukubopha nokuqinisa izimbambo.Izimbambo ziyimicu emincane yezinto efakwe phakathi kwe-plies ukunikeza ukusekelwa kwesakhiwo. Ngokuhlanganisa izingxenye kanye nokulandela lezi zimbambo, ikhono lazo lokumelana nokugoba nokugoba liyathuthukiswa. I-adhesive isebenza njengesendlalelo sokuzivikela, inciphisa amathuba okuba nezingxenye ezilimazayo kanye nemikhondo ngesikhathi sokugoba.

Amazinga Wokuhlola Nezitifiketi:

Mayelana nokuhlola kanye nesitifiketi, amabhodi aqinile-flex adlula ezinqubweni ezihlukahlukene ukuze ahlole ukuqina nokuthembeka kwawo. Lezi zivivinyo zibalulekile ekuqinisekiseni ukuthi ibhodi liyahlangabezana nekhwalithi edingekayo kanye namazinga okusebenza.

I-IPC-6013 iyindinganiso ebalulekile elawula ukuhlolwa kwe-rigid-flex, eshicilelwe i-Printed Circuits Council (IPC).Izinga linikeza izidingo ezithile kanye nemibandela yokuhlola lawa mabhodi. Ukuthobela i-IPC-6013 kuqinisekisa ukuthi amabhodi ahlangabezana nemihlahlandlela eyamukelwa yimboni yekhwalithi nokuqina.

Ukuhlolwa kwe-Rigid-flex ngokuvamile kufaka phakathi ukuhlolwa kwemishini nogesi.Ukuhlola okomshini kuhlola amandla ebhodi lesifunda lokumelana nokugoba, ukugoba, nokunye ukucindezeleka komshini elingase libhekane nakho phakathi nokuphila kwalo okusebenzisekayo. Lokhu kuhlola kungase kuhlanganise ukugoba, ukusonta nokudlidliza ibhodi ukuze lilingise izimo zomhlaba wangempela. Linganisa ukumelana kwebhodi nalezi zingcindezi bese ubhala noma yikuphi ukwehluleka noma umonakalo.

Ukuhlolwa kukagesi kuhlola ukusebenza kukagesi nobuqotho bebhodi eliqinile eliguquguqukayo.Lokhu kuhlola kungase kuhlanganise ukuhlola ama-opens, izikhindi, izilinganiso ze-impedance, ubuqotho besignali, nokuhlola kwe-voltage/kwamanje. Ngokwenza lezi zivivinyo zikagesi, kunganqunywa ukuthi ibhodi lihlangabezana nezimfuneko zikagesi ezidingekayo futhi lisebenza kahle.

Ngaphezu kokuhlolwa kwemishini nogesi, okunye ukuhlola kungenziwa ukuze kuhlolwe izici ezithile noma izidingo zamabhodi aqinile-flex.Lokhu kungafaka ukuhlolwa kokusebenza okushisayo, ukubambezeleka komlilo, ukumelana namakhemikhali, ukumelana nomswakama kanye nokwethembeka ngaphansi kwezimo zemvelo ezinzima.

Ukuqinisekisa kuyisici esibalulekile senqubo yokuhlola eguquguqukayo.Uma amabhodi esephumelele ngempumelelo zonke izivivinyo ezidingekayo, angagunyazwa njengokuthobela izindinganiso ezichazwe ku-IPC-6013 noma amanye amazinga afanele embonini. Lesi sitifiketi siqinisekisa amakhasimende nabasebenzisi ukuthi ibhodi ngelekhwalithi ephezulu, lithembekile futhi liqinile.

Ukuqina kwamabhodi e-PCB aqinile aguquguqukayo kuwumphumela wokuklama ngokucophelela, ukukhethwa kwezinto ezibonakalayo, nokucatshangelwa kokukhiqiza.Ngokusebenzisa izinto ezisezingeni eliphezulu, ukusebenzisa izindlela ezifanele zokuguquguquka, ukubhekana nezinselelo zemvelo, kanye nokubeka amasu izingxenye nemikhondo, abakhiqizi bangaqinisekisa ukuthi lawa mabhodi azohlangabezana nezidingo zezicelo ezahlukahlukene. Nakuba ama-PCB aguquguqukayo aqinile enikeza ukuqina okukhethekile, kubalulekile ukusebenza nabaklami abanolwazi nabakhiqizi ukuze uqinisekise ukuthi izidingo ezithile zohlelo lokusebenza ngalunye ziyahlangatshezwa. Ngokunamathela ezindinganisweni zemboni kanye nokwenza ukuhlola okuphelele, abakhiqizi bangaqinisekisa ukuthi ama-PCB abo aguquguqukayo azoba nokuqina nempilo ende edingekayo emishinini kagesi yanamuhla.

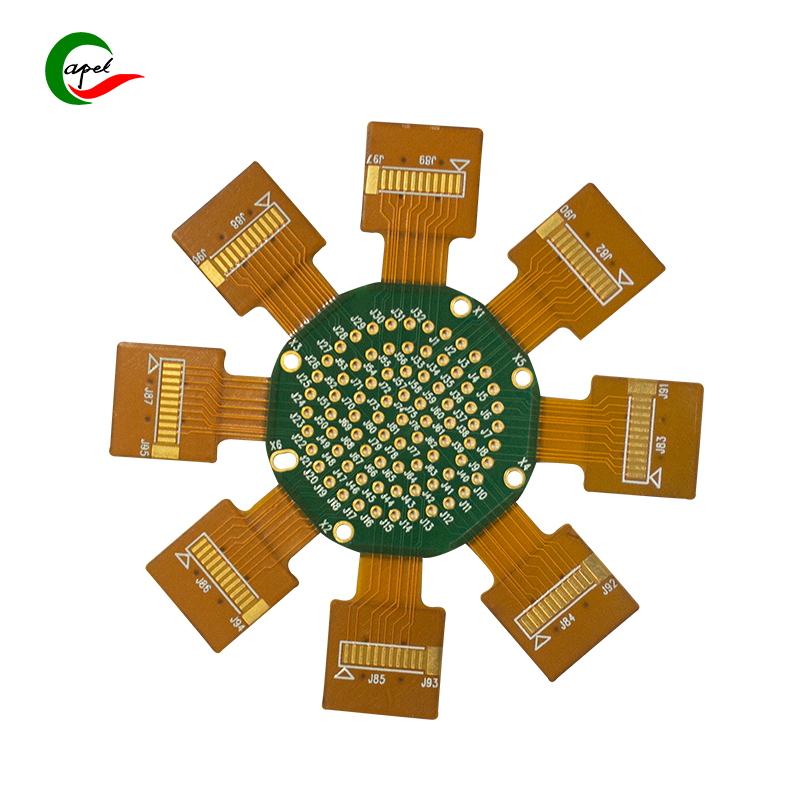

I-Shenzhen Capel Technology Co., Ltd.isungule imboni yayo eqinile ye-pcb ngo-2009 futhi ingumkhiqizi we-Flex Rigid Pcb ochwepheshe. Iminyaka engu-15 yesipiliyoni sephrojekthi esicebile, ukugeleza kwenqubo okuqinile, amakhono obuchwepheshe asezingeni eliphezulu, okokusebenza okuzenzakalelayo okuthuthukisiwe, uhlelo oluphelele lokulawula ikhwalithi, futhi uCapel unethimba lochwepheshe lochwepheshe ukuze anikeze amakhasimende omhlaba ukunemba okuphezulu, ikhwalithi ephezulu ye-1-32 layer rigid flex board, i-hdi Rigid Flex Pcb Fabrication, i-rigid Flex Pcb Fabrication, i-rigid-px-flex pcb prototypes.Izinsizakalo zethu zobuchwepheshe ezisabelayo zangaphambi kokuthengisa kanye nangemuva kokuthengisa kanye nokulethwa okufika ngesikhathi kwenza amakhasimende ethu abambe ngokushesha amathuba emakethe amaphrojekthi awo.

Isikhathi sokuthumela: Aug-28-2023

Emuva