I-HDI (High Density Interconnect) ama-PCB aguquguqukayo aqinile amelela isiqongo sobuchwepheshe bebhodi lesifunda eliphrintiwe elithuthukisiwe, elihlanganisa izinzuzo zamakhono ezintambo ezixhumene kakhulu nokuguquguquka kwamabhodi aguquguqukayo aqinile.Le ndatshana ihlose ukucacisa inqubo yokukhiqiza ye-HDI rigid-flex PCB futhi inikeze imininingwane ebalulekile ngesakhiwo sayo, izinto zokwakha kanye nezinyathelo ezibalulekile zokukhiqiza.Ngokuqonda izinto eziyinkimbinkimbi ezihilelekile, onjiniyela nabaklami bangathuthukisa imiklamo yabo futhi basebenzisane ngempumelelo nabakhiqizi ukuze baguqule imibono yabo emisha ibe ngokoqobo.

1. QondaI-HDI eqinile ye-PCB eguquguqukayo:

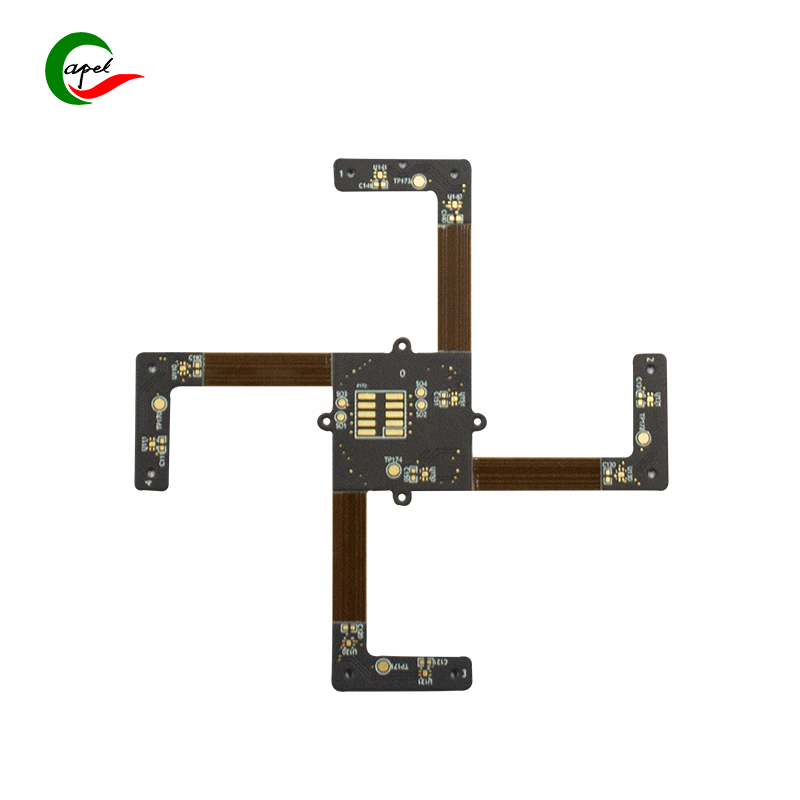

I-HDI (High Density Interconnect) i-rigid-flex PCB iwuhlobo oluthuthukisiwe lwebhodi lesifunda eliphrintiwe elihlanganisa izinzuzo zokuxhumanisa okuphezulu nokuguquguquka.Le nhlanganisela eyingqayizivele ibenza bafaneleke ngokufanelekile ukuhlangabezana nezidingo zemishini yesimanje kagesi.

Uxhumano oluphakeme kakhulu lubhekisela emandleni okuzuza izingxenye eziminyana kakhulu kanye nomzila wesignali ngaphakathi kwesikhala esilinganiselwe sebhodi.Njengoba isidingo samadivaysi amancane, ahlangene aqhubeka nokukhula, ubuchwepheshe be-HDI buvumela ukuklama nokukhiqizwa kwamasekhethi ayinkimbinkimbi ezintweni ezincane zamafomu. Ukuminyana kwe-interconnect eyengeziwe kuvumela ukusebenza okwengeziwe ukuthi kuhlanganiswe kumadivayisi amancane, okuwenza asebenze kahle futhi abe namandla.

Ukuvumelana nezimo kungenye imfanelo ebalulekile ye-HDI rigid-flex PCBs. Lokhu kuvumelana nezimo kuvumela ibhodi ukuthi ligotshwe, ligoqwe noma lisonte ngaphandle kokuphazamisa ukusebenza noma ukwethembeka.Ukuvumelana nezimo kunenzuzo ikakhulukazi kumishini kagesi edinga imiklamo ebonakalayo eyinkimbinkimbi noma edinga ukumelana nokudlidliza, ukushaqeka, noma izindawo ezidlulele. Iphinde inikeze amandla ukuhlanganiswa okungenamthungo kwezingxenye ze-elekthronikhi ezivela ezingxenyeni zebhodi lesifunda ezihlukene, kuqede isidingo sezixhumi ezengeziwe noma izintambo.

Ukusebenzisa ubuchwepheshe be-HDI kunikeza izinzuzo ezimbalwa.Okokuqala, kuthuthukisa kakhulu ubuqotho besignali ngokunciphisa ibanga phakathi kwezingxenye nezixhumi, kunciphise ukulahlekelwa kwesignali, ukuphambana kwe-crosstalk kanye nokuphazanyiswa kwe-electromagnetic. Lokhu kuthuthukisa ukusebenza nokuthembeka kwezinhlelo zokusebenza zedijithali ne-RF ezinesivinini esikhulu. Okwesibili, i-HDI rigid-flex PCB inganciphisa kakhulu usayizi nesisindo semishini kagesi. Ubuchwepheshe be-HDI buqeda isidingo sezixhumi ezengeziwe, izintambo, nokuxhumeka kwebhodi kuya ebhodini, okuvumela imiklamo ehlangene, engasindi. Lokhu kubaluleke kakhulu ezimbonini ezifana ne-aerospace kanye nezinto zikagesi eziphathwayo zabathengi, lapho kubaluleke kakhulu ukonga isisindo nendawo. Ngaphezu kwalokho, ubuchwepheshe be-HDI buphinde buthuthukise ukuthembeka kwemishini kagesi. Ngokunciphisa inani lezixhumanisi, ama-PCB aqinile e-HDI anciphisa ingozi yokwehluleka ngenxa yokuxhumeka okuxekethile noma ukukhathala okuhlangene kwe-solder. Lokhu kuthuthukisa ikhwalithi yomkhiqizo futhi kukhulisa ukuthembeka kwesikhathi eside.

Izinhlelo zokusebenza ze-HDI rigid-flex zitholakala ezimbonini ezihlukahlukene, okuhlanganisa i-aerospace, izinsiza zezokwelapha, ezokuxhumana kanye nogesi wabathengi.Embonini ye-aerospace, ama-PCB e-HDI aqinile asetshenziswa ezinhlelweni zokulawula indiza, ama-avionics, nezinhlelo zokuxhumana ngenxa yobukhulu bawo obuhlangene, isisindo esilula, nekhono lokumelana nezimo ezimbi kakhulu. Emkhakheni wezokwelapha, asetshenziswa emishinini efana nezihlinzeki zenhliziyo, amasistimu wokuthwebula izithombe zezokwelapha, namadivayisi afakelwayo. Ezokuxhumana kanye nezinto zikagesi zabathengi ziyazuza kusukela kusayizi oncishisiwe kanye nokusebenza okuthuthukisiwe kwama-PCB e-HDI rigid-flex kuma-smartphone, amaphilisi, okugqokekayo, namanye amadivayisi aphathekayo.

2.Inqubo yokukhiqiza ye-PCB eqinile ye-HDI: Igxathu emvakwe gxathu

A. Dizayina imikhawulo futhi ulungise amafayela e-CAD:

Isinyathelo sokuqala senqubo yokukhiqiza ye-HDI eqinile-eguquguqukayo ye-PCB ukucabangela izithiyo zokuklama nokulungisa amafayela e-CAD. Izithiyo zedizayini zidlala indima ebalulekile ekunqumeni ukusebenza kwe-PCB, ukwethembeka, kanye nokwenziwa. Ezinye izithiyo zedizayini ezibalulekile okufanele zicatshangelwe yilezi:

Imikhawulo kasayizi:

Usayizi we-PCB uncike ezidingweni zedivayisi lapho isetshenziswa khona. Kuyadingeka ukuqinisekisa ukuthi i-PCB ingena esikhaleni esimisiwe ngaphandle kokuthikameze ukusebenza noma ukwethembeka.

Ukwethembeka:

Idizayini ye-PCB kufanele ithembeke futhi ikwazi ukumelana nezimo zokusebenza ezilindelekile. Izinto ezifana nezinga lokushisa, umswakama, ukudlidliza kanye nokucindezeleka komshini zidinga ukucatshangelwa phakathi nenqubo yokuklama.

Ubuqotho Besiginali:

Amadizayini kufanele acabangele ubuqotho besignali ukuze kuncishiswe ubungozi bokuncishiswa kwesignali, umsindo, noma ukuphazamiseka. Amasiginali wedijithali anesivinini esikhulu kanye ne-RF adinga umzila ngokucophelela nokulawula okuvimbayo.

Ukuphatha Okushisayo:

Ukuphathwa kwe-thermal kubalulekile ekuvimbeleni ukushisa nokuqinisekisa ukusebenza kahle kwezingxenye ze-elekthronikhi. Ukukhishwa kokushisa kungafinyelelwa ngokubekwa ngendlela efanele kwe-thermal vias, osinki okushisa, namaphedi ashisayo. Isofthiwe ye-CAD isetshenziselwa ukudala amafayela esakhiwo se-PCB. Ivumela abaklami ukuthi bachaze ukupakishwa kwesendlalelo, ukubekwa kwengxenye kanye nomzila wokulandelela wethusi. Isofthiwe ye-CAD ihlinzeka ngamathuluzi namandla okumela ngokunembile nokubona imiklamo, okwenza kube lula ukuhlonza nokulungisa noma yiziphi izinkinga ezingaba khona ngaphambi kokukhiqiza.

B. Ukukhethwa Kwezinto Ezibalulekile Nokwakheka Kwesakhiwo:

Ngemva kokulungisa amafayela e-CAD, isinyathelo esilandelayo ukukhetha impahla kanye nomklamo wokuhlanganisa. Ukukhetha izinto ezifanele kubalulekile ukuze kuqinisekiswe ukuthi ama-PCB e-HDI aqinile afinyelela ukusebenza kukagesi okudingekile, ukuphathwa kwezimo ezishisayo, nobuqotho bemishini. Izinto zongqimba eziqinile, njenge-FR-4 noma ama-laminates asebenza kahle kakhulu, zinikeza ukusekela komshini nokuzinza. Isendlalelo esiguquguqukayo ngokuvamile senziwe ngefilimu ye-polyimide noma i-polyester ukuze kube nokuguquguquka nokuqina. Inqubo yokuklama isitaki ihlanganisa ukunquma ukuhlelwa kwezingqimba ezihlukene, okuhlanganisa izendlalelo eziqinile neziguquguqukayo, ukujiya kwethusi, nezinto ze-dielectric. Idizayini yesitaki kufanele icabangele izici ezifana nobuqotho besignali, isilawuli se-impedance, nokusabalalisa amandla. Ukubekwa kahle kwesendlalelo nokukhethwa kwezinto kusiza ukuqinisekisa ukudluliswa kwesignali okuphumelelayo, ukunciphisa i-crosstalk futhi kunikeze ukuguquguquka okudingekayo.

C. I-Laser drilling kanye nokwakheka kwe-microhole:

Ukubhoboza i-laser kuyisinyathelo esibalulekile ekudaleni ama-microvia omzila asondelene kakhulu kuma-HDI PCB. Ama-Microvias ayizimbobo ezincane ezisetshenziselwa ukuxhuma izingqimba ezihlukene ze-PCB, okuvumela ukuxhumana okuphezulu kokuminyana. Ukubhola nge-laser kunikeza izinzuzo ezimbalwa kunezindlela zendabuko zokumba imishini. Ivumela izimbobo ezincane, okuvumela ukuminyana okuphezulu kwemizila kanye nemiklamo ehlangene. I-Laser drilling iphinde inikeze ukunemba okukhulu nokulawula, kunciphisa ubungozi bokungahambi kahle noma ukulimala kwezinto ezizungezile. Enqubweni yokumba i-laser, i-laser beam egxilile isetshenziselwa ukukhipha izinto ezibonakalayo, ukudala izimbobo ezincane. Izimbobo zibe sezenziwe ngensimbi ukuze zinikeze ukuguquguquka phakathi kwezingqimba, okuvumela ukudluliswa okuphumelelayo kwamasignali.

D. I-Chemical copper Plating:

I-electroless copper plating iyisinyathelo esibalulekile enqubweni yokukhiqiza yamabhodi e-HDI aqinile-flex. Inqubo ihlanganisa ukufaka ungqimba oluncane lwethusi ngaphakathi kwama-micropores nangaphezulu kwe-PCB. Ukubaluleka kwe-electroless copper plating kusemandleni ayo okuqinisekisa ukuxhumana okuthembekile kukagesi kanye nokudluliswa kwesignali okuhle. Isendlalelo sethusi sigcwalisa ama-microvias futhi sixhuma izingqimba ezihlukene ze-PCB, senze indlela yokuqondisa yamasignali. Iphinde inikeze indawo ethengiswayo yokunamathiselwe kwengxenye. Inqubo ye-electroless copper plating ibandakanya izinyathelo ezimbalwa, okuhlanganisa ukulungiswa kwendawo, ukwenza kusebenze kanye nokubeka. I-PCB iqala ukuhlanzwa futhi isebenze ukuze ikhuthaze ukunamathela. Ukusabela kwamakhemikhali kusetshenziswa isixazululo esiqukethe ama-ion ethusi endaweni ye-PCB, kufakwa ungqimba oluncane lwethusi.

E. Ukudluliswa Kwesithombe kanye Nokwakheka Kwezinto:

Ukudluliswa kwesithombe kanye ne-photolithography yizingxenye zenqubo yokukhiqiza ye-HDI eqinile eguquguqukayo ye-PCB. Lezi zinyathelo zihlanganisa ukusebenzisa okokusebenza kwe-photoresist ukuze udale iphethini yesifunda endaweni ye-PCB futhi uyiveze ekukhanyeni kwe-UV ngokusebenzisa imaski enephethini. Phakathi nenqubo yokudlulisa isithombe, okokusebenza kwe-photoresist kusetshenziswa endaweni ye-PCB. Izinto ze-Photoresist zizwela ukukhanya kwe-UV futhi zingavezwa ngokukhetha. I-PCB ibe isiqondaniswa ne-photomask enephethini futhi ukukhanya kwe-UV kudluliselwa ezindaweni ezicacile ze-photomask ukuze kuvezwe i-photoresist. Ngemva kokuchayeka, i-PCB ithuthukiswa ukuze isuse i-photoresist engaveziwe, ishiye iphethini yesifunda oyifunayo. Lawa maphethini asebenza njengezendlalelo ezivikelayo ezinqubweni ezilandelayo. Ukwakha imikhondo yesifunda, amakhemikhali e-etching asetshenziselwa ukususa ithusi elingafuneki. Izindawo ezingahlanganiswa ne-photoresist zivezwa ku-etchant, esusa ngokukhetha ithusi, ishiya imikhondo yesifunda oyifunayo.

F. Inqubo ye-Etching kanye ne-electroplating:

Injongo yenqubo yokufaka iwukuba ukususa ithusi eliningi nokudala imikhondo yesekethe ku-HDI rigid-flex PCB. I-Etching ihlanganisa ukusebenzisa i-etchant, ngokuvamile i-asidi noma isixazululo samakhemikhali, ukuze ukhethe ngokukhetha ithusi elingafunwa. I-etching ilawulwa isendlalelo se-photoresist esivikelayo esivimbela i-etchant ekuhlaseleni imikhondo yesekethe edingekayo. Lawula ngokucophelela ubude besikhathi nokugxila kwe-etchant ukuze ufinyelele ububanzi bokulandelela obufunekayo nokujula. Ngemuva kokufakwa, i-photoresist esele iyakhumulwa ukuze kuvezwe imikhondo yesekethe. Inqubo yokuhlubula ihilela ukusebenzisa izincibilikisi ukuze incibilike futhi isuse i-photoresist, ishiye imikhondo yesifunda ehlanzekile futhi echazwe kahle. Ukuqinisa ukulandelana kwesifunda nokuqinisekisa ukuqhutshwa okufanele, inqubo yokucwenga iyadingeka. Lokhu kuhilela ukufaka ungqimba olwengeziwe lwethusi kumkhondo wesekethe ngenqubo yokucwenga i-electroplating noma engenawo ugesi. Ugqinsi kanye nokufana kwe-copper plating kubalulekile ekuzuzeni uxhumano oluthembekile lukagesi.

G. Isicelo semaski ye-Solder kanye nokuhlanganiswa kwengxenye:

Isicelo semaski ye-Solder kanye nokuhlanganiswa kwengxenye kuyizinyathelo ezibalulekile kunqubo yokukhiqiza ye-HDI eqinile-flex PCB. Sebenzisa imaski ye-solder ukuvikela iminonjana yethusi futhi unikeze ukwahlukanisa phakathi kwazo. Imaski ye-Solder yenza ungqimba oluvikelayo phezu kwayo yonke indawo ye-PCB, ngaphandle kwezindawo ezidinga ukusoda, njengamaphedi ezingxenye nama-vias. Lokhu kusiza ukuvimbela ibhuloho le-solder kanye nezikhindi ngesikhathi sokuhlanganiswa. Ukuhlanganiswa kwezingxenye kuhilela ukubeka izinto ze-elekthronikhi ku-PCB futhi zihlanganiswe endaweni yazo. Izingxenye zibekwe ngokucophelela futhi ziqondaniswe nephedi lokumisa ukuze kuqinisekiswe ukuxhumana kahle kukagesi. Sebenzisa amasu e-soldering afana nokugeleza kabusha noma i-wave soldering kuye ngohlobo lwengxenye kanye nezidingo zokuhlanganisa. Inqubo ye-reflow soldering ihlanganisa ukushisisa i-PCB kuzinga lokushisa elithile elibangela ukuthi i-solder incibilike futhi yakhe ukuxhumana okuhlala njalo phakathi komkhondo wengxenye namaphedi e-PCB. I-Wave soldering ijwayele ukusetshenziselwa izingxenye zembobo, lapho i-PCB idlula igagasi le-solder elincibilikisiwe ukuze yakhe uxhumano.

H. Ukuhlola Nokulawula Ikhwalithi:

Isinyathelo sokugcina senqubo yokukhiqiza ye-HDI eqinile-eguquguqukayo ye-PCB ukuhlola nokulawula ikhwalithi. Ukuhlola okuqinile kubalulekile ukuze kuqinisekiswe ukusebenza kwe-PCB, ukwethembeka nokusebenza. Yenza izivivinyo zikagesi ukuze uhlole izikhindi, ukuvuleka, nokuqhubeka. Lokhu kuhilela ukusebenzisa ama-voltage athile nama-currents ku-PCB kanye nokulinganisa impendulo kusetshenziswa okokusebenza kokuhlola okuzenzakalelayo. Ukuhlolwa okubonakalayo kuyenziwa futhi ukuze kuqinisekiswe ikhwalithi ehlanganyelwe ye-solder, ukubekwa kwengxenye, kanye nokuhlanzeka sekukonke kwe-PCB. Isiza ukukhomba noma ikuphi ukonakala okungaba khona njengezingxenye ezingaqondani kahle, amabhuloho e-solder, noma ukungcola. Ngaphezu kwalokho, ukuhlaziywa kwengcindezi yokushisa kungenziwa ukuze kuhlolwe ikhono le-PCB lokumelana nokuhamba ngebhayisikili kwezinga lokushisa noma ukushaqeka okushisayo. Lokhu kubaluleke kakhulu ezinhlelweni zokusebenza lapho i-PCB ichayekile ekushintsheni kwezinga lokushisa elidlulele. Ngesikhathi nangemva kwesinyathelo ngasinye senqubo yokukhiqiza, izinyathelo zokulawula ikhwalithi ziyasetshenziswa ukuze kuqinisekiswe ukuthi i-PCB ihlangabezana nemibandela edingekayo kanye namazinga. Lokhu kufaka phakathi amapharamitha enqubo yokuqapha, ukulawulwa kwenqubo yezibalo (SPC), kanye nokwenza ukucwaninga ngezikhathi ezithile ukuze kuhlonzwe futhi kulungiswe noma yikuphi ukuchezuka noma okudidayo.

3.Izinselelo ezibhekene nokukhiqiza amabhodi e-HDI aqinile-flex:

Ukukhiqiza amabhodi aqinile e-HDI kuveza ubunkimbinkimbi nezinselele okumelwe ziphathwe ngokucophelela ukuze kuqinisekiswe umkhiqizo wokugcina wekhwalithi ephezulu.Lezi zinselelo zizungeza izindawo ezintathu ezibalulekile: ukuqondanisa okunembile, ukukhubazeka kwendawo, kanye nezinguquko ze-impedance ngesikhathi sokugcoba.

Ukuqondanisa okunembayo kubalulekile kumabhodi e-HDI aguquguqukayo aqinile ngoba afaka izendlalelo eziningi nezinto okufanele zibekwe ngendlela enembile. Ukufinyelela ukuqondanisa okunembayo kudinga ukuphathwa ngokucophelela nokubeka izendlalelo ezihlukene ukuqinisekisa ukuthi i-vias nezinye izingxenye ziqondaniswe kahle. Noma yikuphi ukungaqondi kahle kungabangela izinkinga ezinkulu njengokulahlekelwa kwesignali, izikhindi, noma amakhefu. Abakhiqizi kufanele batshale imali kumishini ethuthukisiwe nobuchwepheshe ukuze baqinisekise ukuqondanisa okunembayo kuyo yonke inqubo yokukhiqiza.

Ukugwema izinkinga ezingaphezulu kungenye inselele enkulu. Phakathi nenqubo yokukhiqiza, ukonakala kwendawo okufana nokuklwebheka, ukubola, noma ukungcola kungase kwenzeke, kuthinte ukusebenza nokuthembeka kwamabhodi e-HDI aqinile-flex.Lezi zinkinga zingaphazamisa ukuxhumana kukagesi, zithinte ubuqotho besignali, noma zenze ibhodi lihluleke ngokuphelele. Ukuze uvimbele ukonakala kwendawo, izinyathelo eziqinile zokulawula izinga kufanele zithathwe, okuhlanganisa ukuphathwa ngokucophelela, ukuhlolwa njalo, kanye nokusetshenziswa kwendawo ehlanzekile ngesikhathi sokukhiqiza.

Ukunciphisa izinguquko ze-impedance phakathi ne-lamination kubalulekile ekugcineni ukusebenza kukagesi kwamabhodi we-HDI rigid-flex board.I-Lamination ihlanganisa ukusebenzisa ukushisa nokucindezela ukuhlanganisa izingqimba ezihlukene ndawonye. Kodwa-ke, le nqubo ingase ibangele izinguquko kububanzi obungaguquki be-dielectric kanye nobubanzi be-conductor, okuholela ekushintsheni okungathandeki kwe-impedance. Ukulawula inqubo ye-lamination ukuze kuncishiswe lezi zinguquko kudinga ukulawula okunembile kwezinga lokushisa, ingcindezi, nesikhathi, kanye nokunamathela ngokuqinile emibhalweni yokuklama. Ngaphezu kwalokho, kungasetshenziswa izindlela ezithuthukile zokuhlola nokuqinisekisa ukuze kuqinisekiswe ukuthi kugcinwa i-impedance edingekayo.

Ukunqoba lezi zinselele ekukhiqizeni amabhodi e-HDI flex kudinga abaklami nabakhiqizi ukuthi basebenzisane eduze kuyo yonke inqubo.Abaqambi kudingeka bacabangele ngokucophelela izingqinamba zokukhiqiza futhi bazidlulisele ngempumelelo kubakhiqizi. Ngakolunye uhlangothi, abakhiqizi kufanele baqonde izidingo zokuklama kanye nemingcele ukuze basebenzise inqubo yokukhiqiza efanele. Ukuhlanganyela kusiza ukubhekana nezinkinga ezingase zibe khona ekuqaleni kwesigaba sokuklama futhi kuqinisekisa ukuthi inqubo yokukhiqiza ithuthukiselwa amabhodi ekhwalithi ephezulu we-HDI rigid-flex.

Isiphetho:

Inqubo yokukhiqiza ye-HDI rigid-flex PCB iwuchungechunge lwezinyathelo eziyinkimbinkimbi kodwa ezibucayi ezidinga ubuchwepheshe obunekhono, obunembayo nobuthembekile.Ukuqonda isigaba ngasinye senqubo kwenza i-Capel ikwazi ukuthuthukisa ikhono layo lokuletha okukhiphayo okuvelele phakathi nezikhathi ezimisiwe eziqinile. Ngokubeka phambili imizamo yokubambisana yokuklama, ukuzenzekelayo kanye nokuthuthukiswa kwenqubo eqhubekayo, i-Capel ingahlala ihamba phambili ekukhiqizeni i-HDI rigid-flex PCB futhi ihlangabezane nesidingo esikhulayo samabhodi anemisebenzi eminingi kanye nokusebenza okuphezulu kuzo zonke izimboni.

Isikhathi sokuthumela: Sep-15-2023

Emuva