Gxumela emhlabeni wezibani zemoto futhi uhlole ubuchwepheshe be-PCB ngemuva kwawo:

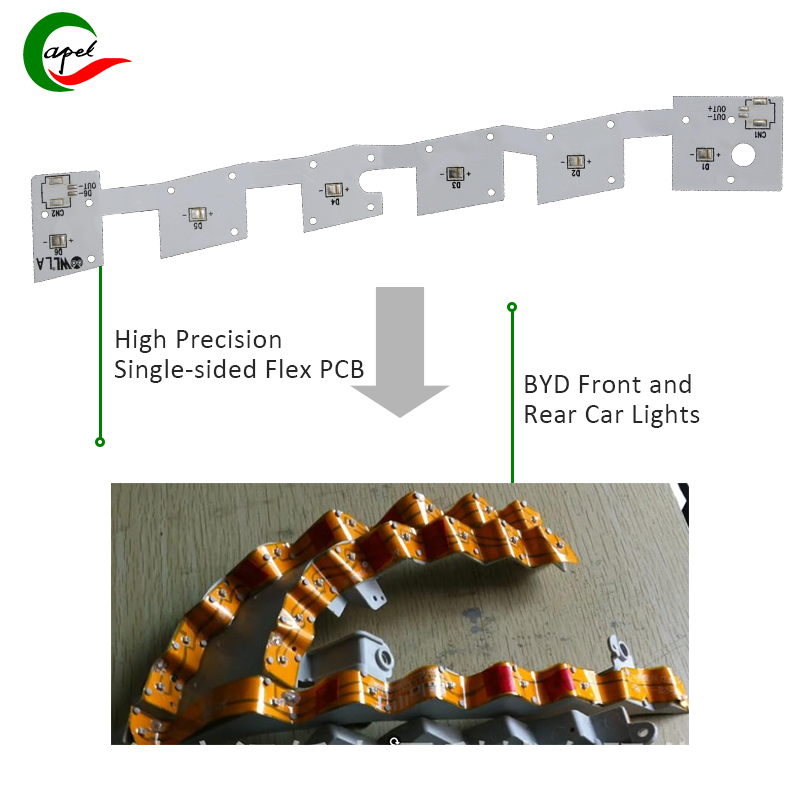

Ingabe ukhangwa ukukhanya okukhangayo kwamalambu ezimoto? Wake wazibuza mayelana nobuchwepheshe ngemuva kwalezi zimangaliso ezimangalisayo? Manje yisikhathi sokuveza umlingo wama-PCB aguquguqukayo anohlangothi olulodwa kanye nendima yawo ekuthuthukiseni ukusebenza kwezibani zezimoto zangaphambili nangemuva. Kule bhulogi, sizohlinzeka ngokuhlaziywa okujulile kwama-PCB avumelana nezimo ohlangothini olulodwa, izici zawo nokuthi angahlanganiswa kanjani ngokuphelele ohlelweni lokukhanyisa imoto, ikakhulukazi imoto ye-BYD.

Imiqondo Eyisisekelo, Ukucatshangelwa Kwedizayini, Izinzuzo kanye Nezicelo Zebhodi Lesifunda Eliphrintiwe Elinohlangothi Olulodwa:

Ngaphambi kokuthi sicwilise, ake sihlole izinto eziyisisekelo. Ama-PCB anohlangothi olulodwa avumelana nezimo, aziwa nangokuthi amabhodi esekethe aphrintiwe avumelana nohlangothi olulodwa, ayinketho ethandwayo ezinhlelweni eziningi ngenxa yokuguquguquka kwawo kanye nokwakheka okuhlangene. Zenziwe nge-polyimide encane noma i-mylar ehlanganiswe nongqimba oluncane lwethusi ohlangothini olulodwa. Lolu ngqimba lwethusi lusebenza njengomkhondo wokuhambisa, okuvumela amasignali kagesi ukuthi ageleze kumjikelezo.

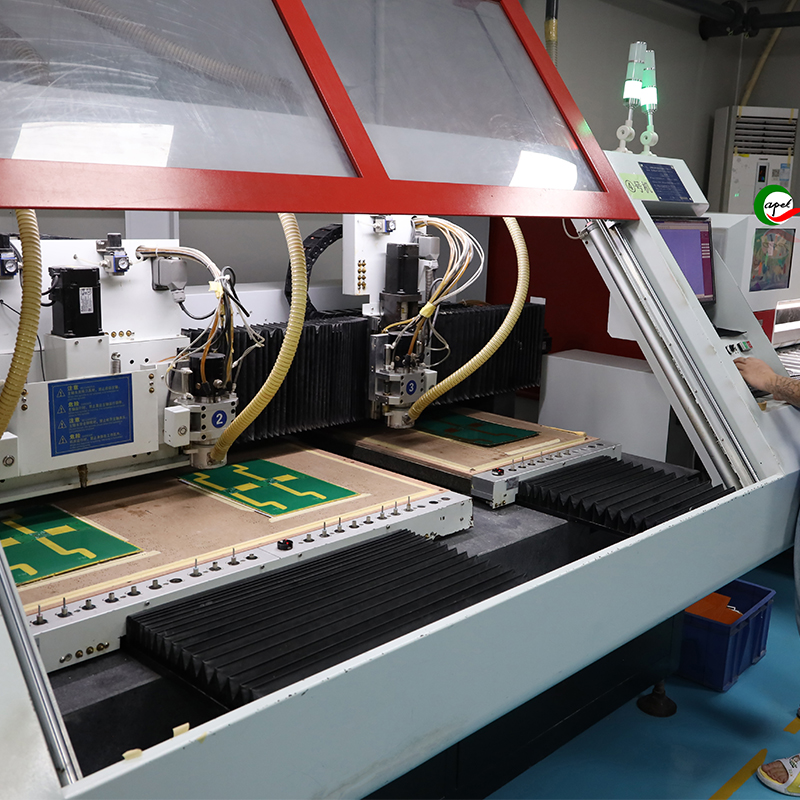

Lapho baklama i-PCB eguquguqukayo yohlangothi olulodwa, onjiniyela kufanele bacabangele izici ezifana nezidingo zemishini yohlelo lokusebenza, ukusebenza kukagesi okufiswayo, kanye nenqubo yokukhiqiza. Ukwengeza, i-insulating efanelekile kanye ne-coatings evikelayo ingasetshenziswa kumasekhethi ukuze kuthuthukiswe ukuqina nokuthembeka.

Ukuvumelana nezimo kwama-PCB aguquguqukayo anohlangothi olulodwa kwenza imiklamo eyinkimbinkimbi futhi ehlangene, iyenze ibe ilungele izinhlelo zokusebenza ezinesikhala lapho ama-PCB endabuko eqinile engakwazi khona. Lokhu kuvumelana nezimo futhi kuvumela i-PCB ukuthi igotshwe, igoqwe noma isonte ngaphandle kokulimaza i-circuitry, iyenze ifanelekele izinhlelo zokusebenza ezidinga ukumelana nokunyakaza noma ukudlidliza.

Ama-PCB aguquguqukayo anohlangothi olulodwa avame ukusetshenziswa ezimbonini ezahlukahlukene ezihlanganisa ezezimoto, i-aerospace, imishini yezokwelapha, izinto zikagesi zabathengi, nokunye. Ukuguquguquka kwabo nokuklama okuhlangene kubenza bafanelekele izinhlelo zokusebenza ezifana nezinto ezigqokwayo, omakhalekhukhwini, amakhamera, izinzwa kanye nezinye izinto zikagesi lapho ubukhulu, isisindo kanye nokuguquguquka kuwukucatshangelwa okubalulekile.

Qinisekisa Ukudluliswa Kwamandla Okuphumelelayo Nobuqotho Besiginali Ngobubanzi Nezikhala Ezikhethiwe:

Isici esibalulekile ekuqinisekiseni ukusebenza kahle kwama-PCB aguquguqukayo anohlangothi olulodwa ububanzi bomugqa kanye nesikhala somugqa. Ububanzi bomugqa busho ukujiya noma ububanzi bokulandela umkhondo ku-PCB, kanti iphimbo libhekisela ebangeni eliphakathi kwamathrekhi aseduze. Ukugcina ububanzi obufanele bokulandela kanye nesikhala kubalulekile ekuthuthukiseni ukuxhumana nokunciphisa ukuphazamiseka kwesignali kulawa mabhodi.

Kulolu hlelo lokusebenza lwe-PCB ye-Capel eguquguqukayo yohlangothi olulodwa, inhlanganisela yobubanzi bomugqa nesikhala sokuhamba kahle ngu-1.8 mm no-0.5 mm, ngokulandelanayo. Lawa manani anqunywa ngokucophelela ngokusekelwe ezicini ezifana nohlobo lwesekhethi, amandla okuphatha amanje, kanye nezidingo zesiginali yobuqotho yohlelo lokusebenza oluthile.

Ububanzi bomugqa ongu-1.8mm buhlinzeka ngomthamo owanele wokuthwala wamanje ukuze kuqinisekiswe ukudluliswa kwamandla okuphumelelayo kuyo yonke i-PCB eguquguqukayo yohlangothi olulodwa. Inika amandla i-PCB ukuthi iphathe umthwalo kagesi odingekayo ngenkathi inciphisa ukulahlekelwa okuphikisayo. Lokhu kubaluleke kakhulu ezinhlelweni zokusebenza ezinezidingo zamandla aphezulu uma kuqhathaniswa, njengezinhlelo zokulawula izinjini noma amasekhethi okuphakela amandla.

Ngakolunye uhlangothi, i-pitch engu-0.5mm inikeza imvume edingekayo phakathi kokulandela ukuvimbela ukuphazamiseka kwesignali kanye ne-crosstalk. Isiza ukunciphisa umsindo kagesi kanye nethuba lokungcoliswa kwesignali, iqinisekise ukudluliswa kwedatha okuthembekile nokugcina ubuqotho besignali obufanele. Lokhu kubalulekile ezinhlelweni ezibandakanya amasignali amaza aphezulu, njengamathuluzi okuxhumana angenantambo noma amasekhethi edijithali anesivinini esikhulu.

Ngokugcina inhlanganisela elinganiselayo yobubanzi bomugqa nesikhala somugqa, ama-PCB aguquguqukayo anohlangothi olulodwa angakwazi ukuzuza ukuhanjiswa kukagesi okuhle kakhulu ukuze kuxhumeke kahle futhi okuthembekile kagesi. Lokhu akugcini nje ukuthuthukisa ukusebenza kwemishini kagesi, kodwa futhi kuqinisekisa ukuphila kwabo isikhathi eside nokuqina.

Sengiphetha, ukukhethwa kobubanzi bomugqa kanye nesikhala somugqa kuyisici esibalulekile sokuqinisekisa ukuqhutshwa okuhle kwe-PCB yohlangothi olulodwa oluvumelana nezimo. Ububanzi bomugqa ongu-1.8mm buhlinzeka ngomthamo owanele wokuthwala wamanje, futhi isikhala somugqa ongu-0.5mm sisiza ukwehlisa ukuphazamiseka kwesignali kanye ne-crosstalk. Ukucatshangelwa ngokucophelela kwale mingcele kuqinisekisa ukuthi okokusebenza kwe-elekthronikhi kusebenza ngokwethembeka nangempumelelo ezinhlelweni ezihlukene.

Iphrofayela Ephansi kanye Nezinzuzo Ezivumelana Nezimo Ze-Single-Sided Flex PCB Yezicelo Zezimoto:

Ibhodi le-PCB eliguquguqukayo elinohlangothi olulodwa lingu-0.15mm ubukhulu, futhi ubukhulu buphelele bungu-1.15mm. Le phrofayili emincane ibenza babe lula, okuzuzisa izinhlelo zokusebenza zezimoto lapho ukunciphisa isisindo kuvame ukuhamba phambili. Ukuvumelana nezimo kwalawa ma-PCB kuzivumela ukuthi zivumelane nezimo nezakhiwo ezihlukene, okuvumela ukusetshenziswa kahle kwesikhala ngaphakathi kwemoto.

Ngaphezu kwalokho, ukujiya kwefilimu okungu-50μm kukhulisa ukuqina nokuqina kwalawa ma-PCB. Ifilimu isebenza njengesendlalelo esivikelayo, evikela ukujikeleza ezinseleleni zemvelo ezingaba khona njengothuli, umswakama, ukudlidliza kanye nokushintshashintsha kwezinga lokushisa. Ukuqina okuthuthukile kuqinisekisa ukuphila isikhathi eside kwe-PCB nokwethembeka ezindaweni ezinokhahlo zezimoto.

Ezinhlelweni zezimoto, lapho ama-PCB echayeka ezimeni ezinzima ezifana nokushintsha kwezinga lokushisa, ukudlidliza, nokuphazamiseka kazibuthe kagesi, amajikijolo efilimu elincanyana engeza ungqimba olwengeziwe lwesivikelo kumjikelezo. Kuyasiza ukuvimbela ukulimala kokulandela umkhondo nezingxenye zethusi, ukuqinisekisa ukuthi i-PCB ingakwazi ukumelana nemvelo yokusebenza eyinselele yemoto.

Ukuqina nokuguquguquka kwalawa ma-PCB aguquguqukayo anohlangothi olulodwa kuwenza alungele izinhlelo zokusebenza ezihlukahlukene zezimoto. Zisetshenziswa ezinhlelweni zokulawula, izinzwa, ukukhanyisa, amasistimu omsindo nezinye izingxenye ze-elekthronikhi emotweni. Imvelo engasindi yalawa ma-PCB iphinde ibe negalelo ekuthuthukisweni kokusebenza kahle kukaphethiloli kanye nokwehliswa kwesisindo sisonke, izici ezibalulekile ekwakhiweni kwezimoto zesimanje.

Sekukonke, inhlanganisela yephrofayili emincane, idizayini engasindi, kanye nembobo yefilimu evikelayo yenza lawa ma-PCB aguqukayo anohlangothi olulodwa alungele izinhlelo zokusebenza zezimoto. Ziqinile, ziyakwazi ukumelana nezimo futhi ziyavumelana nezimo, ziqinisekisa ukusebenza okuthembekile nokuphila isikhathi eside ezindaweni eziyinselele.

Ukubaluleka Kokusebenzisa Ama-PCB Okuziphatha Okushisayo Okuphezulu Ezinhlelweni Zokukhanyisa Zezimoto Ukuvimbela Izinkinga Ezihlobene Nokushisa:

Ukusebenza okushisayo kuyisici esibalulekile ezinhlelweni zikagesi, ikakhulukazi ezinhlelweni ezikhiqiza ukushisa okuningi, njengezinhlelo zokukhanyisa izimoto. Kulo mongo, ama-PCB aguquguqukayo anohlangothi olulodwa aziwa ngokusebenza kwawo okushisayo okuhle kakhulu.

Isici esibalulekile ekusebenzeni okushisayo okuphezulu kwama-PCB aguquguqukayo ohlangothini olulodwa ukuqhutshwa kwawo okushisayo. Lolu hlelo lokusebenza lwama-PCB e-Capel lucaciswe nge-thermal conductivity ye-3.00, okubonisa amandla abo okudlulisa ukushisa kahle.

Amanani aphezulu wokusebenza okushisayo akhombisa ukuthi impahla ye-PCB ingaqhuba futhi isuse ukushisa kude nezinto ezikhiqiza ukushisa. Ngokwenza kanjalo, kusiza ukugcina izinga lokushisa eliphezulu lokusebenza kwezingxenye zokukhanyisa ezithambile, ukuvimbela noma yimuphi umonakalo ovela ekukhiqizeni ukushisa okukhulu.

Amasistimu okukhanyisa izimoto, ikakhulukazi lawo asebenzisa ubuchwepheshe be-LED, akhiqiza ukushisa okukhulu ngesikhathi sokusebenza. Isibonelo, izibani ze-LED zikhiqiza ukushisa njengoba zisebenzisa ugesi. Ngaphandle kokukhishwa kokushisa okufanele, lokhu kushisa kungabangela ukuwohloka kokusebenza, ukwehluleka kwengxenye ngaphambi kwesikhathi, kanye nezinkinga zokuphepha.

Ngokuhlanganisa ama-PCB aguquguqukayo ohlangothini olulodwa ane-conductivity ephezulu yokushisa ezinhlelweni zokukhanyisa zezimoto, abakhiqizi bangaqinisekisa ukuchithwa kokushisa okuphumelelayo. Ngakho-ke, lawa ma-PCB adlala indima ebalulekile ekuvimbeleni umonakalo ohlobene nokushisa nokugcina ukwethembeka okuphelele nokuhlala isikhathi eside kwesistimu yokukhanyisa.

Ukwengeza, ukuguquguquka kwe-PCB eguquguqukayo yohlangothi olulodwa ibenza bakwazi ukulolongwa futhi baklanyelwe ukuhlangabezana nezidingo ezithile zezinhlelo zokukhanyisa izimoto. Lokhu kuvumelana nezimo kuqinisekisa ukudluliswa kokushisa okuphumelelayo ngisho nasezikhaleni ezivalekile noma izakhiwo zezintambo eziyinkimbinkimbi. Ngokuvumelana nedizayini yesistimu, i-PCB eguquguqukayo yohlangothi olulodwa ingakhulisa ukusebenza kahle kokupholisa kanye nokuphatha okushisayo.

Lawa ma-PCB e-Capel ane-thermal conductivity engu-3.00 ukuze akhiphe kahle ukushisa futhi avikele izingxenye zokukhanyisa ezintekenteke. Ukusetshenziswa kwabo ezinhlelweni zokukhanyisa izimoto kubalulekile ukuze kuqinisekiswe impilo ende nokuthembeka ngokuvimbela umonakalo ekushiseni ngokweqile.

Indlela Ama-PCB Avumelana Ngayo Ohlangothi Olulodwa Angathuthukisa Ngayo Ukuqina, Ukumelana Nokugqwala Nokuthuthukisa Ukusebenza :

ENIG Qeda: I-PCB inesiphetho se-ENIG (Electroless Nickel Immersion Gold) enogqinsi luka-2-3uin (amayintshi amancane). I-ENIG iyindlela yokwelapha esezingeni eliphezulu embonini ye-elekthronikhi ngenxa yokumelana nokugqwala kwayo okuhle kakhulu kanye nokuqina kwayo. Isendlalelo segolide esincanyana, esilinganayo sinikeza umgoqo ovikelayo ngokumelene ne-oxidation, iqinisekisa ukuqina kwe-PCB nokuvimbela ukonakala kokusebenza okungaba khona ngokuhamba kwesikhathi.

I-1OZ Ukuqina Kwethusi: I-PCB inogqinsi lwethusi oluyi-1OZ (ounce). Lokhu kubhekisela ongqimbeni lwethusi olunesisindo esingu-1 ngonyawo lwesikwele ngasinye. Ukuqina kongqimba lwethusi, kuyancipha ukumelana futhi kungcono ukuqhutshwa kwe-conductivity. Ugqinsi lwethusi lwe-1OZ lubonisa ukuthi i-PCB eguquguqukayo yohlangothi olulodwa ingaqhuba ngempumelelo amasignali kagesi namandla, inciphise ukwehla kwamandla kagesi kanye nokunciphisa isignali okungenzeka ngezendlalelo zethusi ezizacile.

Ukuqina nokuhlanganiswa nepuleti le-aluminium: Ukuhlanganiswa kwe-PCB eguquguqukayo yohlangothi olulodwa nepuleti le-aluminium engu-1.0mm kunomthelela ekuqineni kwayo. Ipuleti le-aluminium liyadwetshwa futhi liboshwe ngeglue ehambisa ukushisa, ethuthukisa ukwakheka okuphelele kwe-PCB. Ukuqina okuhlinzekwa ukuhlanganiswa nepuleti ye-aluminium kubalulekile ekugcineni ukuma kwe-PCB nokuvimbela ukugoba noma ukugoba ngokweqile. Lokhu kubaluleke kakhulu ezinhlelweni zokusebenza lapho i-PCB ingase ibe ngaphansi kokucindezeleka komshini noma ukugobeka njalo, okufana nemishini egqokekayo noma izibonisi eziguquguqukayo.

Ukukhishwa kokushisa okungcono: Ishidi le-aluminium elihlanganiswe ne-adhesive conductive eshisayo aligcini nje ngokuqinisa isakhiwo, kodwa futhi linomphumela ongcono wokushisa ukushisa. I-Aluminium iyikhondatha yokushisa enhle kakhulu, ngakho ukukuhlanganisa kumhlangano we-PCB kungadlulisa ngempumelelo ukushisa kude nezinto eziphehla ukushisa. Amandla athuthukisiwe okususa ukushisa kwama-PCB aguquguqukayo anohlangothi olulodwa abalulekile ezinhlelweni zokusebenza lapho ukuphathwa kwe-thermal kubaluleke kakhulu, okufana nogesi wamandla, ukukhanya kwe-LED, noma amasistimu ezimoto. Kuyasiza ukuvimbela ukushisa ngokweqile futhi iqinisekise ukusebenza okuthembekile kwezingxenye, ekugcineni ithuthukise ukusebenza okuphelele nokuthembeka kwe-PCB.

Ukwelashwa kwe-ENIG 2-3uin ebusweni, ukujiya kwethusi okungu-1OZ, ukuhlanganiswa nepuleti le-aluminium elingu-1.0mm, kanye nokusetshenziswa kosizo lwe-adhesive conductive thermally ukuze kuthuthukiswe ukuqina, ukumelana nokugqwala, ukuguquguquka kukagesi, ukuqina, kanye nokukhipha ukushisa. I-PCB eguquguqukayo yohlangothi olulodwa. Lezi zici ziyenza ifanelekele izinhlelo zokusebenza ezihlukahlukene ezidinga ukusebenza okuthembekile nokuqinile ezindaweni eziyinselele.

Hlola Izinzuzo Zobuchwepheshe Zama-PCB Avumelana Nohlangothi Olulodwa Ezinhlelweni Zokukhanyisa Zezimoto:

Manje njengoba sesizizwisisile izici zama-PCB anohlangothi olulodwa oluvumelana nezimo, ake sihlole ukusetshenziswa kwawo kumalambu angaphambili nangemuva ezimoto, ikakhulukazi izimoto ze-BYD. I-BYD, umkhiqizi wezimoto zikagesi ohamba phambili, ubehamba phambili ekuhlanganiseni nobuchwepheshe besimanje ezimotweni zayo. Ukuhlanganiswa kwe-PCB enohlangothi olulodwa eguquguqukayo ohlelweni lokukhanyisa izimoto lwe-BYD nakanjani kuwushintsho lomdlalo.

Amalambu emoto ngaphambili nangemuva adlala indima ebalulekile ekuqinisekiseni ukuphepha emgwaqeni. Lezi zibani zithuthukisa ukubonakala, zivumela abashayeli ukuthi bezwe indawo ebazungezile futhi basabele ngokufanele. Ukusetshenziswa kwama-PCB aguquguqukayo anohlangothi olulodwa kulawa kuguqule imboni yezimoto ngokuthuthukisa ukusebenza nokusebenza kohlelo lokukhanyisa.

Imvelo engasindi futhi eguquguqukayo yama-PCB aguquguquka ohlangothini olulodwa yenza onjiniyela bakwazi ukuklama amasistimu okukhanyisa ahlangene ngaphandle kokufaka engozini ukusebenza. Ngokusebenzisa lezi zici ze-PCB zokonga isikhala, izimoto ze-BYD zifakwe amalambu angemuva asesitayeleni namahle namalambu. Umphumela awukona nje kuphela ubuhle obuthuthukisiwe kodwa futhi nokuphepha komgwaqo okuthuthukisiwe.

Ngaphezu kwalokho, i-thermal conductivity enhle kakhulu ye-PCB eguquguqukayo yohlangothi olulodwa isiza ukwandisa isikhathi sokuphila nokusebenza kahle kwesistimu yokukhanyisa. Lawa ma-PCB ahlakaza kahle ukushisa okukhiqizwa ama-bulb, avimbele noma yiziphi izinkinga zokushisa ngokweqile. Lokhu kuqinisekisa ukuthi izibani zangaphambili nangemuva zihlala zisebenza isikhathi eside, ngisho nangaphansi kwezimo ezinzima.

Ukuhlanganiswa kwe-PCB eguquguqukayo yohlangothi olulodwa futhi kunika amandla ukulawula okungenamthungo nokwenza ngokwezifiso imiphumela yokukhanyisa. Onjiniyela bangahlela amaphethini okukhanyisa ahlukene kanye nokulandelana kwakhe ukuze bakhe isitayela esiyingqayizivele sezimoto ze-BYD. Lokhu ngokwezifiso kwengeza ukuthinta komuntu siqu ezimotweni, kuzenze zigqame emgwaqeni.

Isifinyezo:

Kafushane, ukuhlaziywa kwama-PCB aguquguqukayo anohlangothi olulodwa lwezinhlelo zokusebenza zokukhanya kwezimoto ngaphambili nangemuva kuveza indima ebalulekile abayidlalayo ekuthuthukiseni ukusebenza nokusebenza kwezinhlelo zokukhanyisa izimoto. Ayisindi, aguquguqukayo, ane-thermal conductivity enhle kakhulu, futhi ahlanganiswe nokwelashwa okungaphezulu namaphaneli e-aluminium, okuwenza alungele izimoto ze-BYD nezinye izinhlelo zokusebenza zezimoto.

Umlingo ongemuva kokukhanya okumangalisayo kwezibani zezimoto usekuklameni okuhle nokuhlanganisa kwe-PCB eguquguqukayo yohlangothi olulodwa. Lawa mabhodi esekethe aphrintiwe anika amandla onjiniyela ukuthi baqhube imingcele yokuqanjwa kabusha ukuze balethe izimoto eziphephile, ezinesitayela esiningi emakethe. Noma ngabe uhamba emigwaqweni yedolobha noma uthatha uhambo olude, ungathemba ukusebenza okuphezulu kwamabhodi e-PCB aguquguqukayo e-Capel ukuze akubonise indlela.

Isikhathi sokuthumela: Aug-19-2023

Emuva