Yethula:

Emkhakheni wezogesi, Amabhodi Esifunda Aphrintiwe (ama-PCB) adlala indima ebalulekile ekuqinisekiseni ukusebenza okungenazihibe kwamadivayisi ahlukahlukene. Ukuqinisekisa amazinga aphezulu ekhwalithi nokuthembeka, kubalulekile ukuthi abakhiqizi be-PCB basebenzise izindlela zokuhlola eziqinile kuyo yonke inqubo yokukhiqiza.Kule bhulogi, sizohlola izindlela zokuhlola ikhwalithi ezisetshenziswa enqubweni yokukhiqiza ye-PCB yenkampani yethu, sigxile ekutholeni kwethu izitifiketi kanye namalungelo obunikazi abonisa ukuzibophezela kwethu ekwenzeni okuhle.

Izitifiketi Nokugunyazwa:

Njengomkhiqizi we-PCB ohlonishwayo, siphethe izitifiketi eziningi ezifakazela ukuthi sithobela izindinganiso eziphakeme kakhulu zomkhakha. Inkampani yethu isiphumelele i-ISO 14001:2015, ISO 9001:2015 kanye nesitifiketi se-IATF16949:2016. Lezi zitifiketi ziqinisekisa ukuzinikela kwethu ekuphathweni kwemvelo, ukuphathwa kwekhwalithi kanye nezinhlelo zokuphatha ikhwalithi yezimoto ngokulandelanayo.

Ngaphezu kwalokho, siyaziqhenya ngokuzuza Amamaki e-UL nawe-ROHS, siphinde sigcizelele ukuzibophezela kwethu ekuthobeleni izindinganiso zokuphepha nemikhawulo ezintweni eziyingozi. Ukuqashelwa nguhulumeni “njengokuthobela inkontileka nokwethembeka” kanye “nebhizinisi likazwelonke lobuchwepheshe obuphezulu” kusho isibopho sethu nokusungula izinto ezintsha embonini.

Ilungelo lobunikazi lokusungula:

Enkampanini yethu, sikholelwa ekubeni phambili entuthukweni yezobuchwepheshe. Sithole isamba samagunya obunikazi angamamodeli angu-16 kanye namalungelo obunikazi okusungulwa, okubonisa imizamo yethu eqhubekayo yokuthuthukisa ikhwalithi nokusebenza kwama-PCB. Lawa malungelo obunikazi awubufakazi bolwazi lwethu nokuzinikela kwethu ekusunguleni izinto ezintsha, okuqinisekisa ukuthi izinqubo zethu zokukhiqiza zithuthukiswa ukuze zisebenze kahle.

Izinyathelo zokuhlola ikhwalithi yangaphambi kokukhiqiza:

Ukulawulwa kwekhwalithi kuqala ekuqaleni kwenqubo yokukhiqiza ye-PCB. Ukuqinisekisa izindinganiso eziphakeme kakhulu, siqale sibuyekeze ngokucophelela imininingwane nezimfuneko zamaklayenti ethu. Ithimba lethu lonjiniyela abanokuhlangenwe nakho lihlaziya ngokucophelela imibhalo yokuklama futhi lixhumane namakhasimende ukuze licacise noma yikuphi ukungaqondakali ngaphambi kokuqhubekela phambili.

Uma umklamo usugunyaziwe, sihlola ngokucophelela futhi sikhethe izinto ezingavuthiwe zekhwalithi ephezulu, okuhlanganisa i-substrate, i-copper foil, noyinki wemaski we-solder. Izinto zethu ezisetshenziswayo zithola ukuhlolwa kwekhwalithi okuqinile ukuze kuqinisekiswe ukuthobelana namazinga omkhakha afana ne-IPC-A-600 ne-IPC-4101.

Phakathi nesigaba sangaphambi kokukhiqiza, senza ukuhlaziywa kwe-design for manufacturability (DFM) ukuze sihlonze noma yiziphi izinkinga ezingaba khona zokukhiqiza futhi siqinisekise isivuno esihle nokwethembeka. Lesi sinyathelo futhi sisivumela ukuthi sinikeze impendulo ebalulekile kumakhasimende ethu, sithuthukise ukuthuthukiswa kwedizayini nokunciphisa izinkinga zekhwalithi ezingaba khona.

Izinyathelo zokuhlola ikhwalithi yenqubo:

Kuyo yonke inqubo yokukhiqiza, sisebenzisa izindlela ezihlukahlukene zokuhlola ikhwalithi ukuze siqinisekise ikhwalithi engaguquki nokwethembeka. Lezi zinyathelo zihlanganisa:

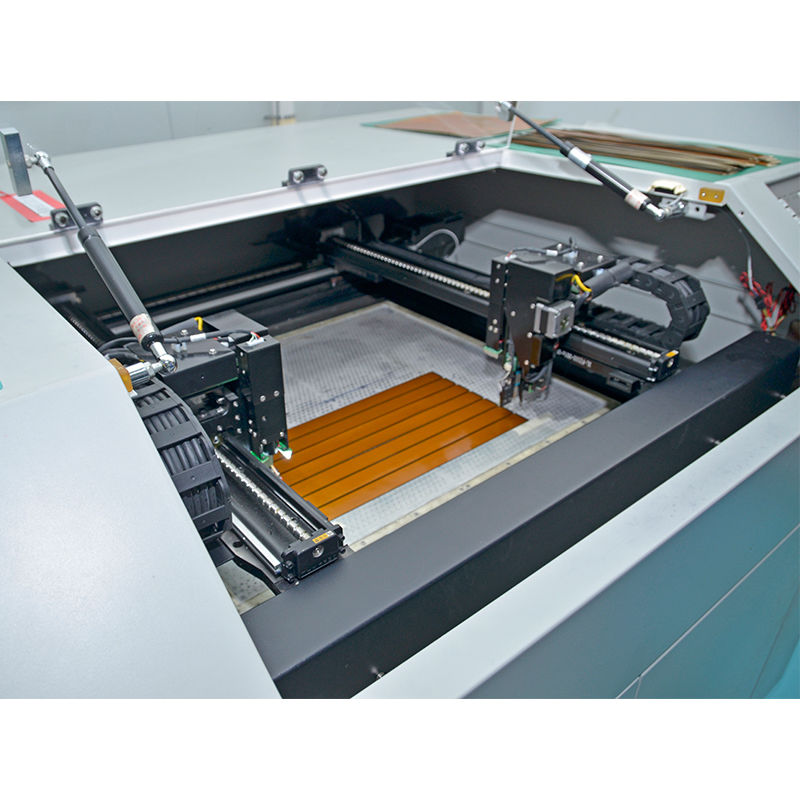

1. Ukuhlola Okuzenzakalelayo Kwe-Optical (AOI): Sisebenzisa amasistimu e-AOI athuthukile, senza ukuhlola okunembile kwama-PCB ezigabeni ezibalulekile, njengangemuva kokufakwa kwe-solder paste, ukubekwa kwengxenye nokusoda. I-AOI isivumela ukuthi sihlonze amaphutha afana nezinkinga zokushisela, izingxenye ezingekho kanye nokungaqondani kahle ngokunemba okuphezulu nokusebenza kahle.

2. Ukuhlolwa kwe-X-ray: Kuma-PCB anezakhiwo eziyinkimbinkimbi nokuminyana okuphezulu, ukuhlolwa kwe-X-ray kusetshenziswa ukuze kutholwe amaphutha afihlekile angenakutholwa ngeso lenyama. Lobu buchwepheshe bokuhlola obungonakali busivumela ukuthi sihlole amajoyinti e-solder, i-vias kanye nezingqimba zangaphakathi ukuze kubonakale ukukhubazeka okufana nokuvula, izikhindi nama-voids.

3. Ukuhlolwa kukagesi: Ngaphambi kokuhlanganiswa kokugcina, senza ukuhlolwa kukagesi okuphelele ukuze siqinisekise ukusebenza nokuthembeka kwe-PCB. Lokhu kuhlola, okuhlanganisa ukuhlolwa kwe-In-Circuit Test (ICT) nokuhlola ukusebenza, kusisiza ukuthi sihlonze noma yiziphi izinkinga zikagesi noma ezisebenzayo ukuze zilungiswe ngokushesha.

4. Ukuhlolwa kwemvelo: Ukuqinisekisa ukuqina kwama-PCB ethu ngaphansi kwezimo ezihlukahlukene zokusebenza, siwafaka ekuhlolweni kwemvelo okuqinile. Lokhu kufaka phakathi ukuhamba ngebhayisikili okushisayo, ukuhlola umswakama, ukuhlolwa kwesifutho sikasawoti, nokunye. Ngalokhu kuhlolwa, sihlola ukusebenza kwe-PCB kumazinga okushisa adlulele, umswakamo, nezimo ezibolayo.

Izinyathelo zokuhlola izinga langemva kokubeletha:

Uma inqubo yokukhiqiza isiqediwe, siyaqhubeka nokuthatha izinyathelo zokuhlola ikhwalithi ukuze siqinisekise ukuthi ama-PCB ekhwalithi ephezulu kuphela afinyelela amakhasimende ethu. Lezi zinyathelo zihlanganisa:

1. Ukuhlola Okubonwayo: Ithimba lethu elinolwazi lokulawula ikhwalithi lihlola ngokucophelela ukuze libone noma yiziphi izinkinga zezimonyo ezifana nokuklwebheka, amabala, noma amaphutha okuphrinta. Lokhu kuqinisekisa ukuthi umkhiqizo wokugcina nawo uhlangabezana nezindinganiso zobuhle.

2. Ukuhlola okusebenzayo: Ukuze siqinisekise ukusebenza okugcwele kwe-PCB, sisebenzisa amathuluzi okuhlola akhethekile kanye nesofthiwe ukwenza ukuhlola okuqinile kokusebenza. Lokhu kusivumela ukuthi siqinisekise ukusebenza kwe-PCB ngaphansi kwezimo zomhlaba wangempela futhi sihlangabezane nezimfuneko eziqondile zamakhasimende ethu.

Ekuphetheni:

Kusukela esigabeni sokuqala sokuklama ukuya emkhiqizweni wokugcina, inkampani yethu iqinisekisa izindlela zokulawula ikhwalithi ezingenakuqhathaniswa kuyo yonke inqubo yokukhiqiza ye-PCB. Izitifiketi zethu, okuhlanganisa i-ISO 14001:2015, ISO 9001:2015 ne-IATF16949:2016, kanye namamaki e-UL ne-ROHS, kugcizelela ukuzibophezela kwethu ekusimameni kwemvelo, ukuphathwa kwekhwalithi nokuhambisana nemithetho yezokuphepha.

Ngaphezu kwalokho, sinamagunya obunikazi angamamodeli angu-16 kanye namalungelo obunikazi okusungula, abonisa ukuphikelela kwethu emisha nasekuthuthukiseni okuqhubekayo. Ngokusebenzisa izindlela zokuhlola ezisezingeni eliphezulu ezifana ne-AOI, ukuhlolwa kwe-X-ray, ukuhlolwa kukagesi, nokuhlola indawo ezungezile, siqinisekisa ukukhiqizwa kwama-PCB asezingeni eliphezulu, athembekile.

Sikhethe njengomkhiqizi wakho othembekile we-PCB futhi uthole isiqinisekiso sokulawulwa kwekhwalithi okungayekethisi kanye nesevisi yamakhasimende ehlukile.

Isikhathi sokuthumela: Oct-30-2023

Emuva