Umhlaba wezogesi wenze inqubekelaphambili enkulu emashumini eminyaka amuva nje, futhi ngemuva kwazo zonke izimangaliso ze-elekthronikhi kukhona ibhodi lesifunda eliphrintiwe (PCB). Lezi zingxenye ezincane kodwa ezibalulekile ziwumgogodla cishe wazo zonke izisetshenziswa zikagesi. Izinhlobo ezahlukene zama-PCB zihlangabezana nezidingo ezahlukene, uhlobo olulodwa i-ENIG PCB.Kule bhulogi, sizocubungula imininingwane ye-ENIG PCB, siveze izici zayo, ukusetshenziswa kwayo nokuthi ihluke kanjani kwezinye izinhlobo zama-PCB.

1.Kuyini ukucwiliswa kwegolide PCB?

Lapha sizohlinzeka ngokubheka okujulile kwama-PCB e-ENIG, okuhlanganisa izingxenye zawo, ukwakhiwa, kanye nenqubo yegolide yokucwiliswa kwe-nickel engenagesi esetshenziselwa ukukhiqiza. Abafundi bazoqonda ngokucacile izici ezihlukile ezenza ama-ENIG PCB agqame.

I-ENIG isifinyezo se-electroless nickel immersion gold plating, okuyindlela evame ukusetshenziswa yokwelapha ngaphezulu ekukhiqizeni i-PCB.Ihlinzeka ngesisombululo esithembekile nesingabizi kakhulu sokuqinisekisa impilo ende nokusebenza kwemishini kagesi. Ama-PCB e-ENIG asetshenziswa kakhulu ezimbonini ezifana nezokuxhumana, i-aerospace, ugesi wabathengi, kanye namadivayisi wezokwelapha.

Ama-PCB e-ENIG akhiwe izingxenye ezintathu eziyinhloko: i-nickel, igolide, kanye nesendlalelo sokuvimbela.Isendlalelo sokuvimbela ngokuvamile senziwe ngongqimba oluncane lwe-nickel engena-electro efakwe phezu kwemikhondo yethusi namaphedi e-PCB. Lesi singqimba se-nickel sisebenza njengesivimbeli sokusabalalisa, esivimbela ithusi ukuthi lingathutheleki ongqimbeni lwegolide ngesikhathi sokubekwa kwegolide. Ngemva kokufaka ungqimba lwe-nickel, ungqimba oluncane lwegolide lufakwa phezulu. Isendlalelo segolide sihlinzeka nge-conductivity enhle kakhulu, ukuqina nokumelana nokugqwala. Iphinde inikeze izinga lokuvikela ngokumelene ne-oxidation, iqinisekisa ukusebenza kwe-PCB yesikhathi eside nokuthembeka.

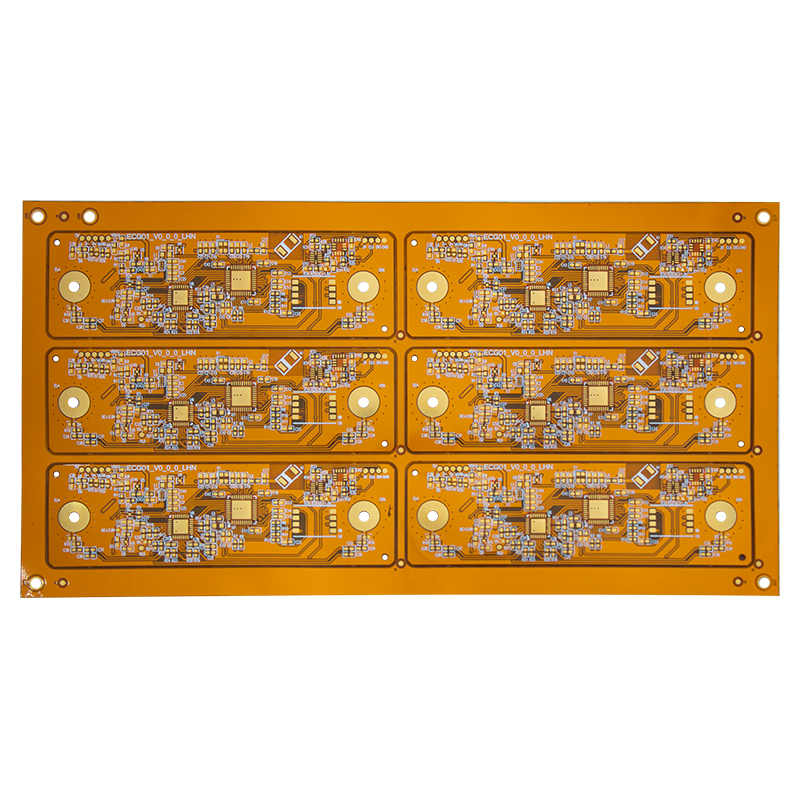

Inqubo yokukhiqiza ye-ENIG PCB ibandakanya izinyathelo ezimbalwa. Okokuqala, i-PCB iyaphathwa futhi ihlanzwe ukuze isuse ukungcola nama-oxide endaweni yethusi. I-PCB ibe isicwiliswa kubhavu wokucwenga we-nickel ongena-electroless, lapho ukusabela kwamakhemikhali kubeka ungqimba lwe-nickel emithonjeni yethusi namaphedi. Ngemuva kokuthi i-nickel ifakiwe, hlambulula futhi uhlanze i-PCB futhi ukuze ususe noma imaphi amakhemikhali asele. Ekugcineni, i-PCB icwiliswa kubhavu wegolide futhi ungqimba oluncane lwegolide lunamekwe endaweni ye-nickel ngokusabela kokusuka. Ubukhulu bongqimba lwegolide bungahluka kuye ngohlelo oluthile kanye nezidingo. I-ENIG PCB inikeza izinzuzo ezimbalwa ngaphezu kwezinye izindlela zokwelapha ezingaphezulu. Enye yezinzuzo eziyinhloko indawo yayo eyisicaba futhi efanayo, eqinisekisa ukudayiswa okuhle kakhulu futhi iyenze ifanelekele izinqubo zokuhlanganisa i-Surface Mount Technology (SMT). Izindawo zegolide nazo zimelana kakhulu ne-oxidation, zisiza ukugcina ukuxhumana okuthembekile kukagesi ngokuhamba kwesikhathi.

Enye inzuzo ye-ENIG PCBs yikhono lokuhlinzeka ngamajoyinti asoda azinzile futhi angaguquki.Indawo eyisicaba futhi ebushelelezi yongqimba lwegolide ikhuthaza ukumanzisa okuhle nokunamathela ngesikhathi senqubo yokuhlanganisa, okuholela ekuhlanganiseni okuqinile nokuthembekile kwe-solder.

Ama-ENIG PCB ayaziwa nangokusebenza kwawo okuphakeme kagesi kanye nobuqotho besignali.Ungqimba lwe-nickel lusebenza njengesithiyo, luvimbele ithusi ukuthi lingasakazeki ongqimbeni lwegolide nokugcina izici zikagesi zesekethe. Ngakolunye uhlangothi, ungqimba lwegolide lunokumelana okuphansi kokuxhumana kanye nokuhamba kahle kagesi, okuqinisekisa ukudluliswa kwesignali okuthembekile.

2.Izinzuzo ze-ENIG PCB

Lapha sibheka izinzuzo ze-ENIG PCBs ezifana nokuthengiselana okuphezulu, ukuqina, ukumelana nokugqwala kanye nokuhamba kukagesi. Lezi zinzuzo zenza i-ENIG PCB ilungele uhla olubanzi lwezinhlelo zokusebenza

I-ENIG PCB noma i-Electroless Nickel Immersion Gold PCB inikezela ngezinzuzo ezimbalwa ngaphezu kwezinye izindlela zokwelapha ezingaphezulu, ikwenze ifanelekele uhla olubanzi lwezinhlelo zokusebenza embonini yezogesi. Ake sihlole ezinye zalezi zinzuzo ngokuningiliziwe.

I-solderability enhle kakhulu:

Ama-ENIG PCB anokuthengiselana okuhle kakhulu, okuwenza alungele izinqubo zokuhlanganisa i-Surface Mount Technology (SMT). Isendlalelo segolide esingaphezulu kwesivimbeli se-nickel sinikeza indawo eyisicaba futhi efanayo, ekhuthaza ukumanzisa okuhle nokunamathela ngesikhathi sokusoda. Lokhu kubangela ukuhlangana okuqinile, okuthembekile kwe-solder, okuqinisekisa ubuqotho kanye nokusebenza komhlangano we-PCB.

Ukuqina:

Ama-ENIG PCB aziwa ngokuqina kwawo nokuphila isikhathi eside. Isendlalelo segolide sisebenza njengesivikelo esivikelayo, sinikeza izinga lokuvikela ngokumelene ne-oxidation kanye nokugqwala. Lokhu kuqinisekisa ukuthi i-PCB ingakwazi ukumelana nezimo zemvelo ezinzima, okuhlanganisa umswakama ophezulu, ukushintsha kwezinga lokushisa kanye nokuchayeka kumakhemikhali. Ukuqina kwama-ENIG PCB kusho ukwethembeka okukhulu nempilo ende, okuwenza afanelekele izinhlelo zokusebenza ezidinga ukusebenza kwesikhathi eside.

Ukumelana Nokugqwala:

I-electroless nickel layer ku-ENIG PCB idala umgoqo phakathi kwemikhondo yethusi nongqimba lwegolide. Lo mgoqo uvimbela ithusi ukuthi lingafuduki liye egolideni ngesikhathi sokubekwa kwegolide. Ngakho-ke, i-ENIG PCB ikhombisa ukumelana nokugqwala okuhle kakhulu nasezindaweni ezigqwalile. Lokhu kuwenza alungele izinhlelo zokusebenza lapho ama-PCB engase echayeke kumswakama, amakhemikhali noma ezinye izinto ezilimazayo.

I-Conductivity:

I-ENIG PCB ibonga kakhulu ngesendlalelo sayo segolide. Igolide liyi-conductor kagesi elihle kakhulu futhi lingadlulisela amasignali kahle kuma-PCB. Indawo yegolide efanayo iphinde iqinisekise ukumelana nokuxhumana okuphansi, inciphisa noma yikuphi ukulahleka kwesignali okungaba khona noma ukuwohloka. Lokhu kwenza i-ENIG PCB ilungele izinhlelo zokusebenza ezidinga ukudluliswa kwesignali yesivinini esikhulu kanye nemvamisa ephezulu, njengokuxhumana ngocingo, i-aerospace kanye nogesi wabathengi.

I-Surface Flatness:

Ama-PCB e-ENIG anendawo eyisicaba futhi efanayo, ebaluleke kakhulu enqubweni yokuhlanganisa engaguquki nethembekile. Indawo eyisicaba iqinisekisa nokusatshalaliswa kwe-solder paste ngesikhathi sokuphrinta i-stencil, ngaleyo ndlela ithuthukise ikhwalithi ehlangene ye-solder. Iphinde yenze kube lula ukubekwa okunembayo kwezingxenye zokukhweza ngaphezulu, kwehlise ubungozi bokungaqondani kahle noma amasekhethi amafushane. Ukucaba komhlaba kwama-PCB we-ENIG kukhulisa ukusebenza kahle kwawo wonke ukukhiqiza futhi kuholela emibuthanweni yekhwalithi ephezulu ye-PCB.

Ukuhambelana kwe-Wire Bonding:

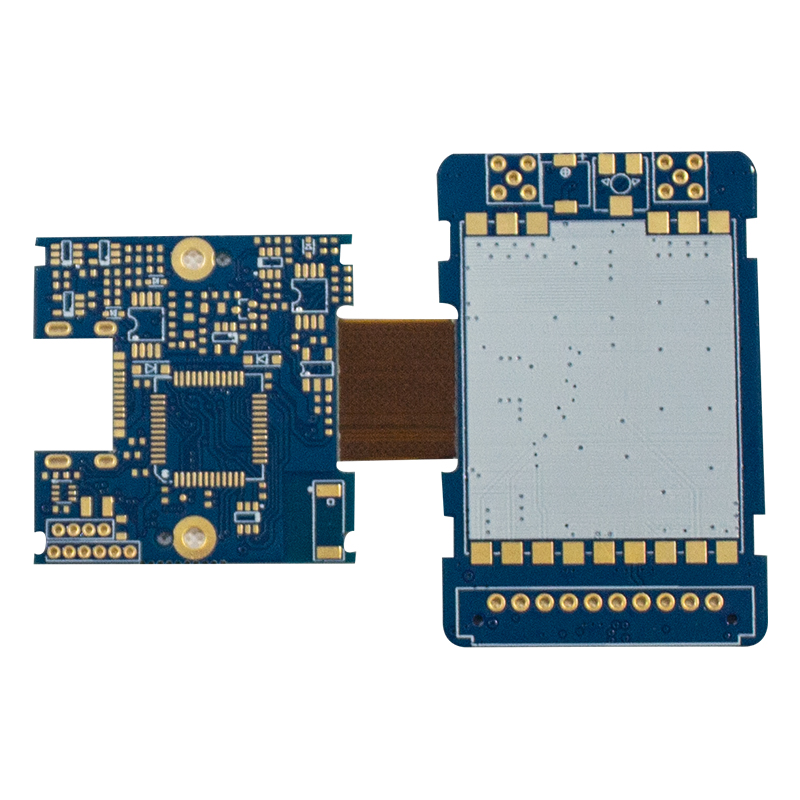

Ama-ENIG PCB aphinde ahambisane nenqubo yokubopha izintambo, lapho izintambo ezithambile ziboshelwa ku-PCB ukuze zenze ukuxhumana kukagesi. Isendlalelo segolide sinikeza indawo efanelekile kakhulu yokubopha ucingo, iqinisekisa isibopho socingo esiqinile nesithembekile. Lokhu kwenza ama-PCB e-ENIG abe yisinqumo esihle kakhulu sezinhlelo zokusebenza ezidinga i-wire bonding, njenge-microelectronics, ugesi wezimoto kanye nemishini yezokwelapha.

Ukuhambisana ne-RoHS:

Ama-ENIG PCB anobungani bemvelo futhi athobela isiyalo Sokuvinjelwa Kwezinto Eziyingozi (RoHS). Inqubo yokubeka i-ENIG ayibandakanyi noma yiziphi izinto eziyingozi, okuyenza ibe ngenye indlela ephephile futhi enobungani nemvelo kwezinye izindlela zokwelapha ezingaphezulu ezingaqukatha izinto ezinobuthi.

3.ENIG PCB vs. nezinye izinhlobo PCB

Ukuqhathanisa okuphelele nezinye izinhlobo ze-PCB ezivamile ezifana ne-FR-4, OSP, HASL kanye ne-Immersion Silver PCB kuzogqamisa izimfanelo eziyingqayizivele, izinzuzo kanye nokubi kwe-PCB ngayinye.

I-FR-4 PCB:I-FR-4 (I-Flame Retardant 4) isetshenziswa kabanzi nge-PCB substrate material. Kuyi-epoxy resin eqiniswe ngemicu yengilazi elukiwe futhi yaziwa ngezici zayo ezinhle zokuvikela ugesi. I-FR-4 PCB inezici ezilandelayo:

inzuzo:

Amandla amahle emishini kanye nokuqina

I-insulation kagesi enhle kakhulu

Ibiza ngempumelelo futhi itholakala kabanzi

ukushiyeka:

Ayilungele ukusetshenziswa kwefrikhwensi ephezulu ngenxa yokulahleka okuphezulu kwe-dielectric

I-thermal conductivity elinganiselwe

Imunca kalula umswakama ngokuhamba kwesikhathi, ibangele izinguquko ze-impedance kanye nokunciphisa isignali

Kuzinhlelo zokusebenza ezidinga ukudluliswa kwesignali yemvamisa ephezulu, i-ENIG PCB ikhethwa kune-FR-4 PCB ngoba i-ENIG inikeza ukusebenza okungcono kagesi nokulahlekelwa kwesignali okuphansi.

I-OSP PCB:I-OSP (i-Organic Solderability Preservative) iwukwelapha okungaphezulu okusetshenziswa kuma-PCB ukuvikela imikhondo yethusi ekufakweni kwe-oxidation. I-OSP PCB inezici ezilandelayo:

inzuzo:

Ivumelana nemvelo futhi iyahambisana ne-RoHS

Izindleko eziphansi uma ziqhathaniswa nezinye izindlela zokwelapha ezingaphezulu

Ilungele ukushelela nokulula

ukushiyeka:

Impilo yeshelufu ephansi uma kuqhathaniswa; ungqimba oluvikelayo luyancipha ngokuhamba kwesikhathi

Ukumelana okulinganiselwe kumswakama kanye nezindawo ezinokhahlo

Ukumelana nokushisa okulinganiselwe

Uma ukumelana nokugqwala, ukuqina kanye nempilo eyandisiwe yesevisi kubalulekile, i-ENIG PCB ikhethwa kune-OSP PCB ngenxa ye-oxidation ephakeme ye-ENIG nokuvikela ukugqwala.

Fafaza i-PCB:I-HASL (Hot Air Solder Leveling) iyindlela yokwelapha engaphezulu lapho i-

I-PCB icwiliswa ku-solder encibilikisiwe bese ihlelwa ngomoya oshisayo. I-HASL PCB inezici ezilandelayo:

inzuzo:Ibiza ngempumelelo futhi itholakala kabanzi

I-solderability enhle kanye ne-coplanarity

Ifanele ngokusebenzisa izingxenye zembobo

ukushiyeka:

Ingaphezulu alilingani futhi kunezinkinga ezingaba khona zokuhlangana

Izembatho eziwugqinsi zingase zingahambelani nezingxenye zephimbo elihle

Ingenwa ukushaqeka okushisayo kanye ne-oxidation ngesikhathi sokuphinda kufakwe i-solder

Ama-PCB we-ENIG akhethwa ngaphezu kwe-HASL PCB yezinhlelo zokusebenza ezidinga ukuthengiselana okuhle kakhulu, izindawo eziyisicaba, ukuhlangana okungcono, nokuhambisana nezingxenye zephimbo elihle.

I-PCB yesiliva yokucwiliswa:Isiliva lokucwiliswa kuyindlela yokwelapha engaphezulu lapho i-PCB icwiliswa kubhavu oyisiliva, idale ungqimba oluncane lwesiliva phezu kwemikhondo yethusi. I-Immersion Silver PCB inezici ezilandelayo:

inzuzo:

Excellent conductivity kagesi kanye solderability

I-flatness enhle kanye ne-coplanarity

Ifanele izingxenye zephimbo elihle

ukushiyeka:

Impilo yeshelufu enomkhawulo ngenxa yokonakala ngokuhamba kwesikhathi

Kuyazwela ekuphathweni nasekungcolisweni ngesikhathi sokuhlanganisa

Ayifanele ukusetshenziswa kwezinga lokushisa eliphezulu

Lapho ukuqina, ukumelana nokugqwala kanye nempilo yeshalofu eyandisiwe kuyadingeka, i-ENIG PCB ikhethwa kune-PCB yesiliva yokucwiliswa ngoba i-ENIG inokumelana okuphezulu nokonakala nokuhambisana kangcono nezicelo zokushisa okuphezulu.

4.Ukusetshenziswa kwe-ENIG PCB

I-ENIG PCB (okungukuthi i-Electroless Nickel Immersion Gold PCB) isetshenziswa kakhulu ezimbonini ezihlukahlukene ngenxa yezinzuzo zayo ezihlukahlukene ngaphezu kwezinye izinhlobo ze-PCB.Lesi sigaba sihlola izimboni ezihlukahlukene ezisebenzisa i-ENIG PCBs, sigcizelela ukubaluleka kwazo kuma-electronics abathengi, i-aerospace kanye nokuzivikela, imishini yezokwelapha. , kanye ne-automation yezimboni.

Imikhiqizo kagesi yabathengi:

Ama-PCB e-ENIG adlala indima ebalulekile ku-elekthronikhi yabathengi lapho usayizi ohlangene, ukusebenza kwesivinini esikhulu nokwethembeka kubalulekile. Asetshenziswa kuma-smartphones, amaphilisi, ama-laptops, ama-game consoles, namanye amadivaysi kagesi. Ukusebenza okuhle kakhulu kwe-ENIG nokulahlekelwa kokufaka okuphansi kuyenza ilungele izinhlelo zokusebenza zemvamisa ephezulu, okuvumela amazinga okudlulisa idatha asheshe, ubuqotho besignali, kanye nokuncipha kokuphazamiseka kazibuthe kagesi. Ngaphezu kwalokho, ama-ENIG PCB ahlinzeka ngokuthengiswa okuhle, okubalulekile ngesikhathi sokuhlanganiswa kwezingxenye ze-elekthronikhi eziyinkimbinkimbi.

I-Aerospace nokuvikela:

Imboni ye-aerospace neyezokuvikela inezidingo eziqinile zezinhlelo ze-elekthronikhi ngenxa yezimo zokusebenza ezinzima, amazinga okushisa aphezulu kanye namazinga aphezulu okuthembeka. Ama-PCB e-ENIG asetshenziswa kakhulu kuma-avionics, izinhlelo zesathelayithi, imishini ye-radar kanye ne-electronics yebanga lezempi. Ukumelana nokugqwala okukhethekile kwe-ENIG kuyenza ifanelekele impilo enwetshiwe yesevisi ezindaweni eziyinselele. Ukwengeza, ubukhulu bayo obufanayo kanye nokucaba kuqinisekisa ukusebenza okungaguquki nokuthembeka.

Imishini yezokwelapha:

Emkhakheni wezokwelapha, ama-PCB e-ENIG asetshenziswa ezinhlobonhlobo zezicelo, okuhlanganisa izinhlelo zokuqapha isiguli, imishini yokuxilonga, imishini yokuthwebula izithombe, izinsimbi zokuhlinza kanye namadivayisi afakelwayo. I-biocompatibility ye-ENIG kanye nokumelana nokugqwala kuyenza ifaneleke izinto zezokwelapha ezihlangana noketshezi lomzimba noma ezibhekana nezinqubo zokuvala inzalo. Ngaphezu kwalokho, ubuso obushelelezi be-ENIG kanye nokuthengiselana kuvumela ukuxhumana okunembile kanye nokuhlanganiswa kwezingxenye ze-elekthronikhi eziyinkimbinkimbi emishinini yezokwelapha. imboni ezenzakalelayo:

Ama-PCB e-ENIG asetshenziswa kakhulu ezinhlelweni ezishintshayo zezimboni, okubandakanya izinhlelo zokulawula inqubo, amarobhothi, amadrayivu ezimoto, izinsiza zikagesi, nezinzwa. Ukuthembeka nokungaguquguquki kwe-ENIG kuyenza ibe ukukhetha okuhle kakhulu kwezicelo zezimboni ezidinga ukusebenza okuqhubekayo kanye nokumelana nezindawo ezinokhahlo. I-solderability enhle kakhulu ye-ENIG iqinisekisa ukuxhumana okuthembekile kumandla aphezulu kanye nezicelo zokushisa okuphezulu, okuhlinzeka ukuqina okudingekile nokuzinza kwezinhlelo ezishintshayo zezimboni.

Ukwengeza, ama-PCB e-ENIG asetshenziswa kwezinye izimboni ezinjengezezimoto, ezokuxhumana, zamandla, kanye namadivayisi we-IoT (I-inthanethi Yezinto).Imboni yezimoto isebenzisa ama-PCB e-ENIG kugesi wezimoto, amayunithi okulawula injini, izinhlelo zokuphepha nezinhlelo zokuzijabulisa. Amanethiwekhi eTelecom athembele kuma-PCB e-ENIG ukuze akhe iziteshi eziyisisekelo, amarutha, amaswishi kanye nemishini yezokuxhumana. Emkhakheni wezamandla, ama-ENIG PCB asetshenziswa ekukhiqizeni amandla, ezinhlelweni zokusabalalisa kanye nezinhlelo zamandla avuselelekayo. Ukwengeza, ama-PCB e-ENIG ayingxenye ebalulekile yamadivayisi e-IoT, axhuma amadivaysi ahlukahlukene futhi anike amandla ukushintshana kwedatha nokuzenzakalelayo.

5.ENIG PCB Manufacturing and Design Ukucatshangelwa

Lapho uklama futhi ukhiqiza ama-ENIG PCB, kunezici ezimbalwa ezibalulekile okufanele zicatshangelwe ukuze kuqinisekiswe ukusebenza kahle nokuthembeka. Nansi eminye imihlahlandlela ebalulekile yokuklama nezinqubo zokukhiqiza eziqondene nama-ENIG PCBs:

Idizayini yephedi:

Idizayini yephedi ye-ENIG PCB ibalulekile ukuze kuqinisekiswe ukuthi i-soldering efanele kanye nokwethembeka kokuxhumana. Amaphedi kufanele aklanywe ngobukhulu obufanele, okuhlanganisa ububanzi, ubude, nesikhala, ukuze ahambisane nengxenye yomthofu kanye nokunamathisela kwe-solder. I-pad surface finish kufanele ibe bushelelezi futhi ihlanzeke ukuvumela ukumanzisa okufanele ngesikhathi senqubo yokuhlanganisa.

Landelela ububanzi nesikhala:

Ububanzi bokulandelela nesikhala kufanele kuthobelane namazinga omkhakha kanye nezidingo eziqondile ze-PCB. Ukuqinisekisa ubukhulu obufanele kungavimbela izinkinga ezinjengokuphazamiseka kwesignali, amasekhethi amafushane, nokungaqini kahle kukagesi.

Ubukhulu bebhodi nokufana:

I-ENIG PCB iqukethe ungqimba lwe-nickel engena-electroless kanye nongqimba lwegolide olucwilisiwe. Ukujiya kwamapulangwe kufanele kulawulwe ngaphakathi kokubekezelelana okuthile ukuze kuqinisekiswe ukumbozwa okufanayo kwendawo yonke ye-PCB. Ubukhulu be-plating obufanayo bubalulekile ekusebenzeni okungaguquki kukagesi kanye namajoyinti e-solder athembekile.

Isicelo se-mask solder:

Ukusebenzisa kahle imaskhi ye-solder kubalulekile ekuvikeleni iminonjana ye-PCB nokuvimbela amabhuloho athengiswayo. Imaski ye-solder kufanele isetshenziswe ngokulinganayo futhi ngokunembile ukuze kuqinisekiswe ukuthi iphedi eveziwe inesikhala esidingekayo sokuvula imaski yezingxenye zokunamathisela.

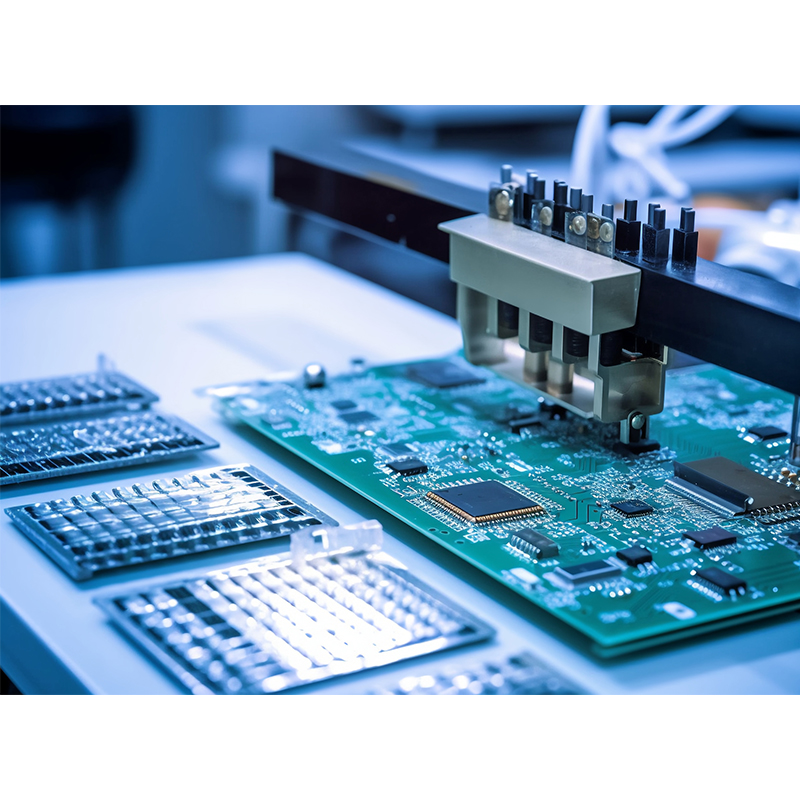

Idizayini Yesifanekiso Se-Solder Namathisela:

Lapho ubuchwepheshe be-surface mount (SMT) busetshenziselwa ukuhlanganiswa kwezingxenye, ama-solder paste stencil asetshenziselwa ukufaka ngokunembile ukunamathisela kwe-solder kumaphedi e-PCB. Idizayini ye-stencil kufanele ihambisane kahle nesakhiwo sephedi futhi ivumele ukubekwa okunembile kwe-solder paste ukuze kuqinisekiswe ukwakheka okuhlangene kwe-solder ngesikhathi sokugeleza kabusha.

Ukuhlola Ukulawula Ikhwalithi:

Phakathi nenqubo yokukhiqiza, kubalulekile ukwenza ukuhlola kokulawula izinga ukuze kuqinisekiswe ukuthi i-ENIG PCB ihlangabezana nemibandela edingekayo. Lokhu kuhlola kungase kuhlanganise ukuhlolwa okubonakalayo, ukuhlolwa kukagesi kanye nokuhlaziywa okuhlangene kwe-solder. Ukuhlolwa kokulawulwa kwekhwalithi kusiza ukuhlonza noma yiziphi izinkinga phakathi nenqubo yokukhiqiza nokuqinisekisa ukuthi i-PCB eqediwe ihlangabezana namazinga adingekayo.

Ukuhambisana komhlangano:

Kubalulekile ukucabangela ukuhambisana kwe-ENIG surface finishes ngezinqubo ezahlukene zokuhlanganisa. I-solderability kanye nezici zokugeleza kabusha kwe-ENIG kufanele zihambisane nenqubo ethile yokuhlanganisa esetshenzisiwe. Lokhu kufaka phakathi ukucatshangelwa okufana nokukhetha kokunamathisela kwe-solder, ukulungiselelwa kabusha kwephrofayela ye-reflow, nokuhambisana nezinqubo zokudambisa ezingenamthofu (uma zikhona).

Ngokulandela le mihlahlandlela yokuklama kanye nezinqubo zokukhiqiza ze-ENIG PCBs, abakhiqizi bangaqinisekisa ukuthi umkhiqizo wokugcina uhlangabezana nezindinganiso ezidingekayo zokusebenza nokuthembeka. Kubalulekile ukusebenzisana eduze nabakhiqizi be-PCB nozakwethu bomhlangano ukuze kuhlangatshezwane nezidingo ezithile futhi kuqinisekiswe impumelelo yokukhiqiza nokuhlanganisa inqubo.

6.ENIG PCB FAQ

Iyini i-ENIG PCB? Imeleni?

I-ENIG PCB imele i-Electroless Nickel Immersion Gold Printed Circuit Board. Kuyindlela yokwelapha yangaphezulu esetshenziswa kakhulu kuma-PCB futhi ihlinzeka ngokumelana nokugqwala, ukucaba kanye nokuqina okuhle.

Yiziphi izinzuzo zokusebenzisa i-ENIG PCB?

Ama-ENIG PCB anikela ngezinzuzo ezimbalwa, okuhlanganisa ukuthengiswa okuhle kakhulu, ukuguquguquka kukagesi okuphezulu kanye nokumelana nokugqwala. Ukuqedwa kwegolide kunikeza isendlalelo sokuvikela, okuyenza ifaneleke izinhlelo zokusebenza lapho ukwethembeka kubalulekile khona.

Ingabe i-ENIG PCB iyabiza?

Ama-ENIG PCB avame ukubiza kancane uma kuqhathaniswa nezinye izindlela zokwelapha ezingaphezulu. Izindleko ezengeziwe zingenxa yegolide elisetshenziswe enqubweni yokucwiliswa emanzini. Kodwa-ke, izinzuzo nokuthembeka okunikezwa yi-ENIG kuyenza ibe yinketho yokuqala yezinhlelo zokusebenza eziningi, ithethelela izindleko zayo eziphakeme kancane.

Ingabe ikhona imikhawulo ekusebenziseni i-ENIG PCB?

Ngenkathi ama-ENIG PCB anezinzuzo eziningi, futhi anemikhawulo ethile. Isibonelo, izindawo ezisagolide zingaguga kalula uma zingaphansi kwengcindezi eyeqile yemishini noma ukuguga. Ukwengeza, i-ENIG ingase ingafaneleki izicelo ezinezidingo zokushisa okuphezulu noma lapho kusetshenziswa amakhemikhali athile anokhahlo.

Ingabe i-ENIG PCB kulula ukuyithenga?

Yebo, ama-ENIG PCB atholakala kabanzi kubakhiqizi nabahlinzeki be-PCB abahlukahlukene. Ziyizinketho ezijwayelekile zokuqeda futhi zingatholakala kalula ukuze zivumelane nezidingo ezahlukene zephrojekthi. Kunconywa ukuthi uhlole ukutholakala nezikhathi zokulethwa nomkhiqizi noma umphakeli othile.

Ngingakwazi ukusebenza kabusha noma ukulungisa i-ENIG PCB?

Yebo, ama-ENIG PCB angasetshenzwa kabusha noma alungiswe. Kodwa-ke, inqubo yokusebenza kabusha neyokulungisa ye-ENIG ingadinga ukucatshangelwa okukhethekile namasu uma kuqhathaniswa nezinye izindlela zokwelapha ezingaphezulu. Kunconywa ukuthi uthintane nochwepheshe bomsebenzi kabusha we-PCB onolwazi ukuze uqinisekise ukuphathwa ngendlela efanele futhi ugweme ukufaka engozini ubuqotho bendawo yegolide.

Ingabe i-ENIG ingasetshenziselwa ukusoda okunomthofu nokungenamthofu?

Yebo, i-ENIG ingasetshenziswa ngezinqubo zokudambisa ezinomthofu nezingenamthofu. Kodwa-ke, kubalulekile ukuqinisekisa ukuhambisana ne-solder ethile yokunamathisela kanye nephrofayili yokugeleza kabusha esetshenzisiwe. Ukuze kuzuzwe amajoyinti e-solder athembekile ngesikhathi sokuhlanganiswa, imingcele ye-welding kufanele ilungiswe ngokufanele.

Inqubo ye-ENIG iyisixazululo esithembekile nesingabizi kakhulu kubakhiqizi nabathanda izinto zikagesi. Inhlanganisela yesivimbo se-nickel esincanyana, esifakwe ngokulinganayo kanye nongqimba lwangaphezulu olusagolide kunikeza indawo efanelekile yokuqeda ukuze kuqinisekiswe impilo ende nokusebenza kwamadivayisi kagesi. Kungakhathaliseki ukuthi kwezokuxhumana ngezingcingo, i-aerospace noma izinto zikagesi zabathengi, ama-ENIG PCB ayaqhubeka nokudlala indima ebalulekile ekuthuthukisweni kobuchwepheshe nasekulolongeni ikusasa lezinto zikagesi.

Isikhathi sokuthumela: Sep-13-2023

Emuva