Yethula:

Emhlabeni wanamuhla oqhutshwa ubuchwepheshe, isidingo samabhodi esekethe aphrintiwe ayinkimbinkimbi navumelana nezimo (PCBs) sikhula ngokushesha. Kusukela kumasistimu ekhompuyutha asebenza kahle kakhulu kuye ezintweni ezigqokwayo kanye nemishini yezokwelapha, lawa ma-PCB athuthukile abe yingxenye ebalulekile yezinto zikagesi zesimanje. Kodwa-ke, njengoba izidingo eziyinkimbinkimbi kanye nokuvumelana nezimo zanda, siyanda nesidingo sobuchwepheshe bokukhiqiza obusezingeni eliphezulu obungakwazi ukuhlangabezana nalezi zidingo eziyingqayizivele.Kule bhulogi, sizohlola isimo esithuthukayo sokukhiqizwa kwe-PCB futhi sixoxe ngokuthi iyakwazi yini ukuhlangabezana nezidingo zama-PCB ayinkimbinkimbi navumelana nezimo.

Funda mayelana nama-PCB ayinkimbinkimbi navumelana nezimo:

Ama-PCB ayinkimbinkimbi abonakala ngemiklamo eyinkimbinkimbi ehlanganisa imisebenzi eminingi ngaphakathi kwesikhala esilinganiselwe. Lokhu kufaka phakathi ama-PCB anezingqimba eziningi, amabhodi e-high-density interconnect (HDI), kanye nama-PCB anama-via angaboni futhi agqitshwe. Ama-PCB aguqukayo, ngakolunye uhlangothi, aklanyelwe ukugoba noma ukusonteka ngaphandle kokulimaza ukujikeleza, awenze alungele izinhlelo zokusebenza lapho ukuguquguquka nokusebenza kwendawo kubalulekile. Lawa ma-PCB ngokuvamile asebenzisa ama-substrates avumelana nezimo njenge-polyimide noma i-polyester.

Ukunyuka kobuchwepheshe bokukhiqiza obuphambili:

Izindlela zokukhiqiza ze-PCB zendabuko, ezifana ne-etching, lamination, njll., azanele ukuhlangabezana nezidingo zama-PCB ayinkimbinkimbi, aguquguqukayo. Lokhu kuye kwaholela ekuthuthukisweni kobuchwepheshe obuhlukahlukene bokukhiqiza obunikeza ukunemba okukhulu, ukuguquguquka nokusebenza kahle.

1. I-Laser Direct Imaging (LDI):Ubuchwepheshe be-LDI busebenzisa ama-laser ukuveza ngokuqondile ama-substrates e-PCB, okuqeda isidingo samaski ezithombe adla isikhathi kanye namaphutha. Ubuchwepheshe buvumela ukukhiqizwa kwamasekhethi amahle kakhulu, imikhondo emincane kanye nama-vias amancane, abalulekile kuma-PCB ayinkimbinkimbi.

2. Ukukhiqiza Okungeziwe:Ukukhiqiza okungeziwe noma ukuphrinta kwe-3D kuguqule ukukhiqizwa kwama-PCB ayinkimbinkimbi futhi aguquguqukayo. Kwenza kube lula ukwakha imiklamo eyinkimbinkimbi, ikakhulukazi yama-prototypes nokukhiqizwa kwevolumu ephansi. Ukukhiqiza okungeziwe kuvumela ukuphindaphinda okusheshayo nokwenza ngokwezifiso, kusiza abaklami nabakhiqizi bahlangabezane nezidingo eziyingqayizivele zama-PCB ayinkimbinkimbi naguquguqukayo.

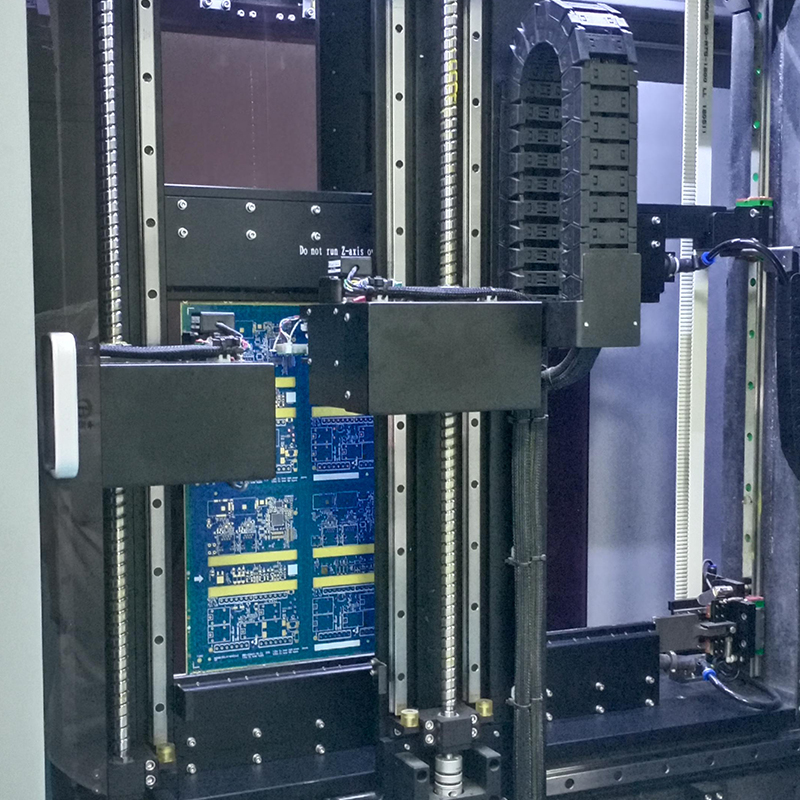

3. Ukuphatha i-substrate eguquguqukayo:Ngokwesiko, ama-PCB aqinile ayeyinto evamile, ekhawulela amathuba okuklama futhi enciphisa ukuguquguquka kwezinhlelo ze-elekthronikhi. Kodwa-ke, ukuthuthuka kwezinto ezisetshenziswayo kanye nobuchwepheshe bokucubungula kuye kwavula izindlela ezintsha zokukhiqiza amabhodi wesifunda aphrintiwe aguquguqukayo. Abakhiqizi manje sebehlonyiswe ngemishini ekhethekile eqinisekisa ukuphathwa ngendlela efanele kanye nokuhambisana kwama-substrates aguquguqukayo, okunciphisa ubungozi bokulimala ngesikhathi sokukhiqiza.

Izinselelo nezisombululo:

Nakuba ubuchwepheshe bokukhiqiza obuthuthukisiwe buqhubeka buthuthuka, izinselele zisadinga ukunqotshwa ukuze kuhlangatshezwane ngokugcwele nezidingo zokukhiqiza zama-PCB ayinkimbinkimbi, aguquguqukayo.

1. Izindleko:Ukusebenzisa ubuchwepheshe bokukhiqiza obuthuthukisiwe ngokuvamile kudinga izindleko eziphezulu. Lokhu kungase kubangelwe ekutshalweni kwezimali kokuqala okudingekayo kumishini, ukuqeqeshwa kanye nezinsizakusebenza ezikhethekile. Kodwa-ke, njengoba lobu buchwepheshe busakazeka kakhulu futhi isidingo sikhuphuka, umnotho wesilinganiso kulindeleke ukuthi wehlise izindleko.

2. Amakhono nokuqeqeshwa:Ukwamukela ubuchwepheshe obusha bokukhiqiza kudinga ochwepheshe abanekhono ekusebenzeni nasekugcineni imishini ethuthukisiwe. Izinkampani zidinga ukutshala izimali ezinhlelweni zokuqeqesha eziqhubekayo futhi zihehe ithalente ukuze ziqinisekise ukuguquguquka okushelelayo kulobu buchwepheshe obusha.

3. Amazinga nokulawulwa kwekhwalithi:Njengoba ubuchwepheshe be-PCB buqhubeka buthuthuka, sekubalulekile ukusungula amazinga embonini nokusebenzisa izinyathelo eziqinile zokulawula ikhwalithi. Abakhiqizi, abalawuli kanye nezinhlangano zezimboni kudingeka basebenzisane ukuze kuqinisekiswe ukwethembeka nokuphepha kwama-PCB ayinkimbinkimbi navumelana nezimo.

Ngokufigqiwe:

Iqhutshwa yizidingo ezikhulayo zezinhlelo zesimanje ze-elekthronikhi, izidingo zokukhiqiza zama-PCB ayinkimbinkimbi futhi aguquguqukayo zihlala zishintsha.Nakuba ubuchwepheshe bokukhiqiza obuthuthukisiwe obufana ne-laser imaging eqondile kanye nokukhiqiza okungeziwe kuthuthukise kakhulu amakhono okukhiqiza e-PCB, kusenezinselele okufanele sizinqobe mayelana nezindleko, amakhono kanye nokulawulwa kwekhwalithi. Kodwa-ke, ngemizamo eqhubekayo kanye nezinhlelo zokusebenzisana, indawo yokukhiqiza isilungele ukuhlangabezana futhi idlule izidingo zama-PCB ayinkimbinkimbi navumelana nezimo. Njengoba ubuchwepheshe buqhubeka buthuthuka, singalindela ukuqamba okusha okuqhubekayo ezinqubweni zokukhiqiza ukuze kuqinisekiswe ukuhlanganiswa okungenamthungo kwama-PCB kuzinhlelo zokusebenza ze-elekthronikhi ezihamba phambili.

Isikhathi sokuthumela: Oct-30-2023

Emuva