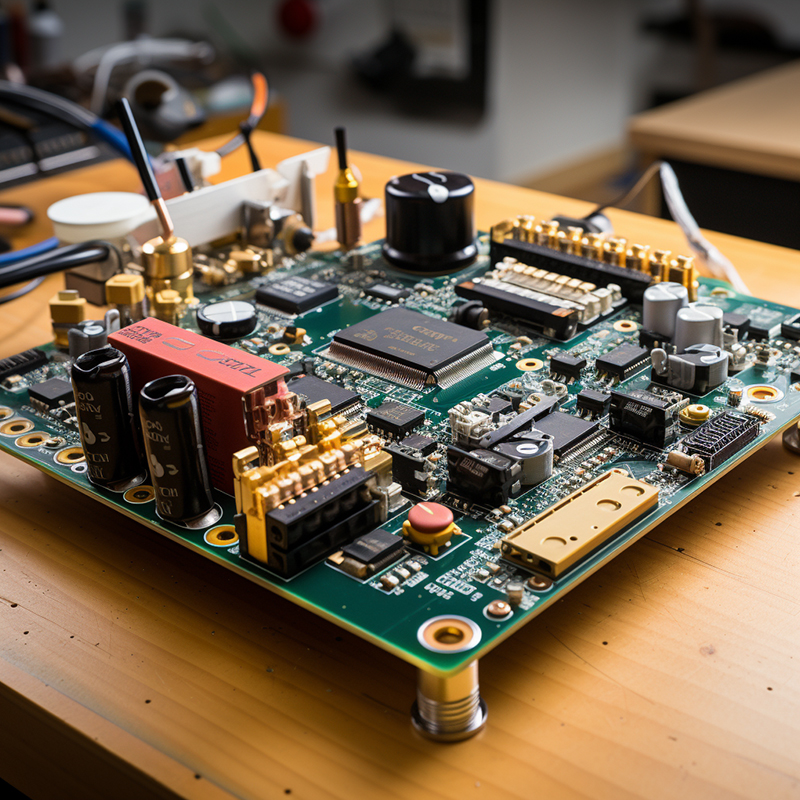

Lapho uklama i-PCB eguquguqukayo eqinile (ibhodi lesifunda eliphrintiwe), kuneziqondiso ezimbalwa eziyisisekelo okufanele zilandelwe. Le mihlahlandlela iqinisekisa ukuthi ama-PCB aqinile, ayasebenza, futhi anokwethenjelwa.Kulokhu okuthunyelwe kwebhulogi, sizobhekisisa imihlahlandlela yedizayini evamile yama-PCB aguquguqukayo futhi siqonde ukubaluleka kwawo ekufezeni ukusebenza kahle. Ngakho-ke, ake siqale!

1. Hlela isakhiwo sebhodi lakho:

Ukuhlela ngokucophelela ukwakheka kwebhodi kubalulekile kuma-PCB aguquguqukayo. Ukunquma indawo yezingxenye eziqinile nezivumelana nezimo, ukubekwa kwengxenye nezindlela zomzila kubalulekile. Isakhiwo kufanele sithuthukiswe ukuze kuncishiswe ingcindezi kanye nobunzima ezindaweni eziguquguqukayo ngesikhathi sokuhlanganisa nokusebenza.

2. Gwema ukugoba okubukhali kanye nengcindezi:

Enye yezindlela eziyinhloko zokuklama ukugwema ukugoba okubukhali nokucindezeleka ngokweqile ezindaweni eziguqukayo. Ukugoba okubukhali kungabangela umonakalo ezintweni eziguquguqukayo, okuholela ekuncipheni kwempilo yesevisi kanye nokwehluleka okungenzeka. Abaqambi kufanele baqinisekise ukugoba kancane kancane futhi basebenzise imikhondo egobile ukuvimbela ukugxila kwengcindezi.

3. Nciphisa inani lezinguquko eziguquguqukayo ukuya kweziqinile:

Ukushintsha okuningi phakathi kwezindawo eziguquguqukayo neziqinile kufanele kugcinwe kuncane. Iphuzu ngalinye loshintsho lidala ukugxilisana kokucindezeleka komshini okwenza buthaka ubuqotho buphelele bebhodi. Ukukhawulela lezi zinguquko kusiza ukuthuthukisa ukuthembeka nokuqina.

4. Sebenzisa ububanzi bekhondatha obanele:

Ububanzi bekhondatha budlala indima ebalulekile ekwehliseni ukumelana nemiphumela yokushisa. Kunconywa ukuthi kusetshenziswe imikhondo ebanzi ezindaweni eziqinile ukuze kuthwale imisinga ephakeme kanye nemikhondo emincane ezindaweni eziguquguqukayo ukuze kuncishiswe ingcindezi. Ububanzi be-conductor obanele bubuye buvumele ubuqotho besignali engcono nokulawulwa kwe-impedance.

5. Gcina ukujiya kwethusi okwanele:

Ukuqinisekisa ukuqhutshwa kahle kukagesi kanye nokuchithwa kokushisa, kubalulekile ukugcina ukushuba okwanele kwethusi kuzo zombili izindawo eziqinile neziguquguqukayo. Isendlalelo sethusi esiwugqinsi sikhulisa amandla emishini futhi sinciphise ukumelana nogesi, ngaleyo ndlela sithuthukise ukusebenza kukonke kwe-PCB.

6. Kuhlanganiswe ne-impedance elawulwayo:

Kuzinhlelo zokusebenza ezinesivinini esikhulu, i-impedance elawulwayo ibalulekile. Abaqambi kufanele abale ngokucophelela ububanzi bokulandelela kanye nogqinsi lwe-dielectric ukuze bafinyelele i-impedance edingekayo. Ukufanisa okunembile kwe-impedance kusiza ukuvimbela ukubonakaliswa kwesignali nokuqinisekisa ukusebenza okuthembekile.

7. Landela imihlahlandlela yokuzinza kwe-dimensional:

Ukunwetshwa kwe-thermal nokufinyela kungathinta kakhulu ukusebenza kwama-PCB aguquguqukayo. Abaqambi kufanele banake kakhulu ukuzinza kwe-dimensional kwezinto ezisetshenziswayo. Ukukhetha izinto ezinama-coefficients afanayo okwandisa ukushisa kungasiza ekunciphiseni ingozi yokwehluleka ngenxa yokucindezeleka ngokweqile.

8. Qiniseka ukuthi izingxenye zibekwe ngendlela efanele:

Izingxenye ezibekwe ngamasu zibalulekile ekulawuleni okushisayo kanye nokunciphisa ingozi yokucindezeleka kwemishini. Kungcono kakhulu ukubeka izingxenye ezisindayo eduze nezindawo eziqinile ukuvimbela izingxenye eziguquguqukayo ekuguquguqukeni ngokweqile nasekucindezelekeni. Ukubeka ngokucophelela futhi kusiza emzileni osebenzayo kanye nesiginali yobuqotho.

9. Hlola futhi uqinisekise umklamo:

Ukuhlolwa okubanzi nokuqinisekiswa kwemiklamo ye-PCB eguquguqukayo kubalulekile ngaphambi kokungena ekukhiqizeni. I-Prototyping kanye nokuhlola okuphelele kusiza ukukhomba noma yimaphi amaphutha edizayini angaba khona, izinkinga zokusebenza, noma izinkinga zokukhiqiza. Ukuqinisekisa okuphindaphindiwe kuqinisekisa ukuthi umklamo wokugcina uhlangabezana nazo zonke izicaciso ezidingekayo.

10. Sebenza nabakhiqizi abanolwazi:

Ukusebenza nomkhiqizi we-PCB onolwazi olunzulu ngobuchwepheshe be-rigid-flex kubalulekile. Ubuchwepheshe babo nolwazi kungasiza kakhulu ekuthuthukiseni imiklamo, kuqinisekise ukukhiqiza okulungile nokuhlangabezana namazinga omkhakha. Bangakwazi futhi ukuqondisa abaklami ekukhetheni izinto ezifanele kanye nezinqubo zokuhlanganisa ngempumelelo kwe-PCB.

Ekuphetheni:

Kubalulekile ukunamathela kule mihlahlandlela yokuklama evamile lapho uklama ama-PCB aguquguqukayo. Ukuhlela okuphelele, ukucatshangelwa kwezakhiwo ezibonakalayo, umzila olawulwayo, nokuhlolwa okufanele konke kuyizici ezibalulekile ekuzuzeni ama-PCB anokwethenjelwa, asebenza kahle aqinile aguquguqukayo. Ngokulandela lezi ziqondiso nokusebenza nomkhiqizi onolwazi, abaklami bangaqinisekisa impumelelo yamaphrojekthi abo e-PCB aguquguqukayo.

Isikhathi sokuthumela: Sep-18-2023

Emuva