Yethula:

Ekwenziweni kwezinto zikagesi, ukuhlanganisa nokuhlolwa kwe-PCB kuyizinyathelo ezibalulekile zokuqinisekisa ukusebenza kahle nokuthembeka kwamabhodi esekethe aphrintiwe (ama-PCB). Ngeminyaka engu-15 yokuhlangenwe nakho kokukhiqiza ibhodi lesifunda, i-Capel yinkampani eyaziwayo ehlinzeka ngokusekela okuphelele kwenqubo yokuhlanganisa nokuhlolwa kwe-PCB.Kule bhulogi, sizojula ngobungcweti buka-Capel kulezi zindawo, sihlole amakhono abo nokuthi asiza kanjani ukunika amandla inqubo yokukhiqiza ye-PCB engenamthungo.

Qonda inqubo yokuhlanganisa i-PCB:

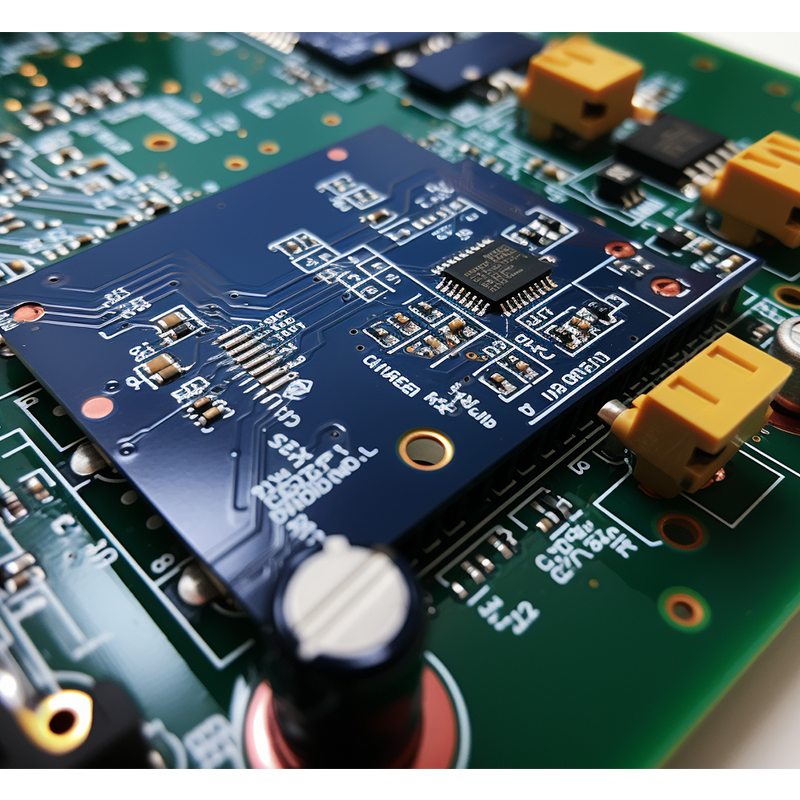

Ukuhlanganiswa kwe-PCB kuyinqubo eyinkimbinkimbi ehlanganisa ukuhlanganisa izingxenye ze-elekthronikhi ebhodini lesifunda eliphrintiwe ukuze kwakhiwe idivayisi esebenzayo. U-Capel uyabuqonda ubunkimbinkimbi bale nqubo futhi unamakhono nemishini edingekayo ukuze isingathe ngobuchwepheshe. Umgomo wabo uwukuthuthukisa inqubo yokuhlanganisa nokuletha ikhwalithi ephezulu kanye nokusebenza okungenazihibe kuyilapho unamathela ezindinganisweni zomkhakha nezindlela ezihamba phambili.

Ukuthengwa kwengxenye:

Esinye sezici ezibalulekile zokuhlangana kwe-PCB ukuthola izingxenye ezifanele. I-Capel iqinisekisa ukuthi izingxenye zangempela nezisezingeni eliphezulu kuphela ezisetshenziselwa ukuhlanganiswa. Inethiwekhi yabo ebanzi yabahlinzeki bempahla ibavumela ukuthi bathole izingxenye kubakhiqizi abathenjwayo, benciphisa ubungozi bezingxenye zomgunyathi noma ezingekho ezingeni. Ukuthola ingxenye esebenzayo akuqinisekisi ukwethembeka kuphela, kodwa futhi kuthuthukisa ukusebenza okuphelele nokuphila isikhathi eside kwe-PCB.

I-Surface Mount Technology (SMT) Assembly:

I-Capel igxile kakhulu ekuhlanganiseni i-Surface Mount Technology (SMT), indlela esetshenziswa kabanzi nephumelelayo yokukhweza izingxenye ze-elekthronikhi kuma-PCB. I-SMT inikeza izinzuzo eziningi, okuhlanganisa ukuminyana okuphezulu kwengxenye, ukwethembeka okukhulu, nezindleko eziphansi zokukhiqiza. Amakhono e-Capel asezingeni eliphezulu okuhlanganisa i-SMT ehlangene nochwepheshe bawo abanamakhono aqinisekisa ukubekwa okunembile, ukudayiswa okunembile kanye nekhwalithi ehlangene efanele, okuholela kuma-PCB athembekile nasebenza kakhulu.

Ngokuhlanganisa imbobo:

Nakuba i-SMT iyindlela ekhethwayo yokuhlanganisa i-PCB, ezinye izingxenye nezinhlelo zokusebenza zidinga ukuhlanganisa ngembobo. I-Capel ihlangabezana nezidingo ezinjalo ngokunikela ngezinsizakalo zokuhlanganisa ngaphandle kwemigodi. Le nqubo ihilela ukufaka umkhondo wengxenye ye-elekthronikhi embotsheni ebhoboziwe ku-PCB bese uwasondezela ngakolunye uhlangothi. Ubungcweti buka-Capel ekuhlanganiseni kwe- through-hole buqinisekisa ukuthi inqubo ayinasici, okuholela ekuxhumekeni okuphephile ngisho nasezicelweni eziyisidingo kakhulu.

Izinqubo zokuhlola ezinzima:

Ku-Capel, ukuhlanganiswa kwe-PCB akugcini ngokubeka ingxenye nokuhlanganisa. Bayabona ukubaluleka kokuhlolwa okuphelele ukuze kutholakale noma yimaphi amaphutha okungenzeka noma amaphutha. Izinqubo zokuhlola zika-Capel zihlanganisa izinhlobonhlobo zezindlela, okuhlanganisa ukuhlola okusebenzayo, ukuhlola kwesifunda (ICT) nokuhlola ukushiswa. Lezi zinqubo zokuhlola eziqinile ziklanyelwe ukuqinisekisa ubuqotho be-PCB ehlanganisiwe, ukuqinisekisa ukuthi ingxenye ngayinye isebenza njengoba kulindelekile nokuthi lonke uhlelo luhlangabezana nokucaciswa okudingekayo.

Ukuhlola okusebenzayo nokuqinisekiswa kwekhwalithi:

Ukuzibophezela kukaCapel kukhwalithi kudlulela ngalé kokuhlolwa kwengxenye ngayinye. Benza ukuhlola okusebenzayo okuphelele ukuze bahlole ukusebenza okuphelele kwe-PCB ehlanganisiwe. Ngokulingisa izimo ezingokoqobo, u-Capel angakwazi ukuhlonza noma yikuphi ukungqubuzana noma izinkinga, enze kube lula ukulungisa okufika ngesikhathi futhi anciphise ukwehluleka kwesikhathi esizayo. Ukugcizelela kwabo ekuqinisekiseni ikhwalithi kuqinisekisa ukuthi ama-PCB agculisayo kuphela alethwa kumakhasimende, ngaleyo ndlela andise ukwaneliseka kwamakhasimende futhi kwehliswe ingozi yokwehluleka kokukhiqiza sekwephuzile.

Ukuthuthukiswa okuqhubekayo nocwaningo nokuthuthukiswa:

Ulwazi lukaCapel ekukhiqizeni ibhodi lesifunda lukhuthaza isiko lokuthuthuka okuqhubekayo nokucwaninga nokuthuthukiswa (R&D). Balwela ngokuqhubekayo ukuthuthukisa ukuhlanganiswa kwe-PCB nezinqubo zokuhlola futhi bahambisane nobuchwepheshe obuguqukayo kanye nezimo zemboni. Lokhu kuzinikela ekusungulweni kwezinto ezintsha kuqinisekisa ukuthi uCapel uhlala ehamba phambili embonini, ehlinzeka amakhasimende ngezixazululo ezisezingeni eliphezulu nokuhlala phambili emqhudelwaneni.

Ekuphetheni:

Ulwazi oluningi luka-Capel ekukhiqizeni ibhodi lesifunda, oluhambisana nobuchwepheshe babo ekuhlanganiseni nasekuhloleni izinqubo ze-PCB, lubenza babe abalingani abathembekile kubakhiqizi bezinto zikagesi emhlabeni wonke. Ngokubeka phambili ukutholakala kwezingxenye, ukusebenzisa amasu okuhlanganisa athuthukile, ukwenza ukuhlolwa okuqinile, nokuhlakulela isiko lokuthuthuka okuqhubekayo, u-Capel usethe isilinganiso esisha ekukhiqizeni i-PCB. Ngokuzibophezela okungaguquki kukhwalithi nokwaneliseka kwamakhasimende, i-Capel ifakazele ukuthi iyinsiza yokuya kuyo ukuze uthole ukwesekwa kwenqubo okuphelele okuhlobene nokuhlanganisa nokuhlolwa kwe-PCB.

Isikhathi sokuthumela: Nov-01-2023

Emuva