Isingeniso:

Amasekhethi e-Rigid-flex athole ukuduma kwe-elekthronikhi ngenxa yokuhlanganiswa kwawo okukhethekile kokuguquguquka nokuqina. Lawa masekhethi aqukethe ingxenye eguquguqukayo ekwazi ukuqondisa kanye nengxenye eqinile enikeza ukuzinza nokusekelwa. Nakuba ama-circuits aqinile asetshenziswa kabanzi kuzinhlelo zokusebenza ezihlukahlukene, umbuzo owodwa ocindezelayo usasele - ingabe angasetshenziswa ngokuphumelelayo ezimweni zamandla aphezulu? Inhloso yalesi sihloko ukuhlola izici nokucatshangelwa kokuhlanganisa amasekhethi e-rigid-flex kuzinhlelo zokusebenza zamandla aphezulu, ukuhlola okuhle nokubi, nokuhlola ezinye izindlela lapho kudingekile. Ngokuqonda amakhono kanye nemikhawulo yamasekhethi aqinile-aguquguqukayo ezinhlelweni zamandla aphezulu, ochwepheshe bezogesi kanye nabantu ngabanye bangenza izinqumo ezinolwazi futhi bakhethe izixazululo zezidingo zabo ezithile.

UkuqondaIzifunda Eziqinile-Flex:

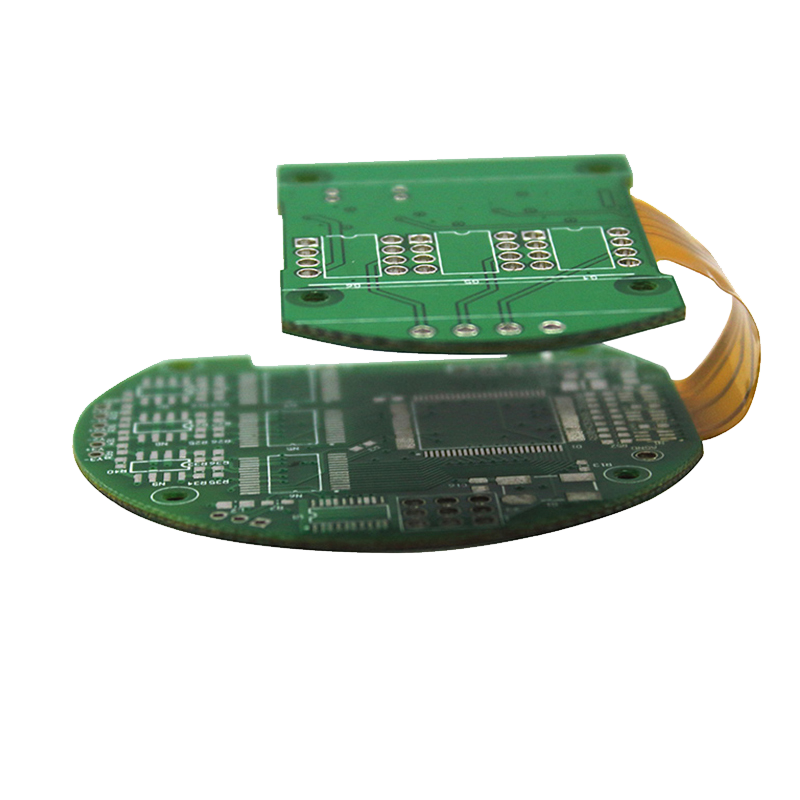

Ukuze ubambe ukusebenza kokusetshenziswa kwamasekhethi e-rigid-flex kuzinhlelo zokusebenza zamandla aphezulu, umuntu kufanele aqale aqonde ukwakhiwa nokwakheka kwalawa mabhodi. Amasekhethi aguquguqukayo aqinile ngokuvamile ahlanganisa izendlalelo eziguqukayo neziqinile, eziwavumela ukuthi agobe noma ahambisane nokuma kwedivayisi agxunyekwe kuwo. Lezi zingqimba zixhunywe izixhumi eziguquguqukayo, okuvumela ukugeleza kwezimpawu zikagesi phakathi kwezingxenye ezahlukene.

Ama-Rigid-flex circuits aklanyelwe ukuba nazo zombili izigaba eziqinile neziguquguqukayo, ukuhlanganisa izinzuzo zazo zombili izinhlobo zamasekhethi. Lezi zifunda ngokuvamile zenziwe ngokushintshanisa izingqimba zezinto eziguquguqukayo neziqinile ndawonye ukuze zakhe ibhodi lesifunda elilodwa.

Isendlalelo esivumelana nezimo ngokuvamile senziwe nge-polyimide noma into efanayo engamelana nokugoba okuphindaphindiwe nokugoba ngaphandle kokulimala. Izendlalelo ziguquguquka kakhulu futhi zingakhiwa zibe izimo ezihlukene, okuvumela isekethe ukuthi ingene ezindaweni ezihlukile noma eziqinile. Isendlalelo esiguquguqukayo futhi sinokumelana okuhle kakhulu nokucindezeleka kwemishini nokudlidliza, okuyenza ifaneleke izinhlelo zokusebenza lapho amasekethe angase abe ngaphansi kokunyakaza noma ukucindezeleka ngokomzimba.

Ngokuphambene, izingqimba eziqinile zenziwe ngezinto ezifana ne-FR-4 noma i-epoxy-based laminates ehlinzeka ngokuzinza nokuqina kumjikelezo. Lezi zingqimba zibalulekile ekusekeleni ingxenye, ukunikeza amandla emishini kanye nokugcina ubuqotho besakhiwo jikelele besifunda. Isigaba esiqinile siphinde siqinisekise ukuthi izingxenye ezibalulekile kanye nokuxhumana kugcinwe endaweni ngokuphephile, kunciphisa ubungozi bokulimala noma ukwehluleka.

Ukuxhuma izingqimba eziguquguqukayo neziqinile, izixhumi eziguquguqukayo zisetshenziswa. Ezaziwa nangokuthi izixhumi eziguqukayo zibe ziqinile, lezi zixhumi zingathwala amasignali kagesi phakathi kwezingxenye ezihlukahlukene ezendlalelo ezahlukene. Idizayinelwe ukuguquguquka futhi iqine, lezi zixhumi zivumela amasekhethi ukuthi aguquguquke futhi aguquguquke ngaphandle kokubeka engcupheni ubuqotho boxhumano lukagesi.

Amasekhethi e-Rigid-flex anikela ngezinzuzo ezimbalwa ezinhlelweni zamandla aphezulu. Ukuguquguquka kwesekethe kuvumela ukuthi ingene ezindaweni eziqinile, iqinisekise ukusetshenziswa kahle kwendawo etholakalayo. Ikhono lokuhambisana nokuma kwedivayisi liphinde linciphise isidingo sezintambo ezengeziwe nezixhumi, ukwenza idizayini ibe lula futhi kunciphise ubungozi bokulahleka kwesignali noma ukuphazamiseka.

Kodwa-ke, kunokucatshangelwa okuthile lapho usebenzisa ama-rigid-flex circuits kuzinhlelo zokusebenza zamandla aphezulu. Amazinga wamandla anyusiwe akhiqiza ukushisa, okungase kuthinte ukusebenza kwesifunda nokuthembeka. Amasu afanele okulawula okushisayo, njengokusetshenziswa kwamasinki okushisa noma i-thermal vias, kufanele asetshenziswe ukuze kukhishwe ukushisa ngokuphumelelayo futhi kuvimbele ukushisa ngokweqile.

Izinzuzo kanye nezinzuzo zamasekethe e-Rigid-Flex:

I-Rigid-flex circuits inezinzuzo eziningi ezibenza bathandeke ezinhlobonhlobo zezinhlelo zokusebenza. Izingxenye zabo eziguquguqukayo zinikeza ukuguquguquka komklamo okuthuthukisiwe, okuvumela ukwakheka kwesekethe okuhlangene nokuyinkimbinkimbi. Ukwengeza, ikhono lokugoba noma ukugoba liqinisekisa ukuthi inani lezixhumi ezidingekayo liyancishiswa, okwandisa ukwethembeka nokuqina. Amasekhethi e-Rigid-flex aphinde anikeze ukonga isisindo okubalulekile uma kuqhathaniswa nama-PCB endabuko aqinile, okuwenza afanelekele okokusebenza okuphathekayo, okungasindi.

Ukuvumelana nezimo komklamo okuthuthukisiwe:Ingxenye eguquguqukayo yesekethe eguquguqukayo eguquguqukayo inikeza abaklami ngesakhiwo esikhulu sesifunda kanye nokuguquguquka kokuklama. Ikhono lesekhethi lokugoba liyivumela ukuthi ingene ezindaweni ezihlukile noma eziqinile, okuvumela amathuba amaningi okuklama nokuphumelela. Lokhu kuvumelana nezimo kubaluleke kakhulu ezinhlelweni zokusebenza ezivimbelwe isikhala, njengamadivayisi agqokekayo, amasistimu omkhathi noma izigxivizo zezokwelapha.

Izixhumi ezincishisiwe:Ama-Rigid-flex circuits angaqeda noma anciphise kakhulu isidingo sezixhumi, okungaba iphuzu lokwehluleka kuma-PCB endabuko aqinile. Ngokuhlanganisa isigaba sesifunda se-flex, izixhumi zingancishiswa, zithuthukise ukwethembeka nokuqina. Ngezixhumi ezimbalwa, kunengozi encane yokuxhuma okuxekethile noma ukungasebenzi kahle kukagesi, okuholela kumasekhethi aqinile futhi athembekile.

Isisindo esincishisiwe:Amasekhethi e-Rigid-flex ahlinzeka ngokonga kwesisindo okubalulekile uma kuqhathaniswa nama-PCB endabuko aqinile. Isisindo esiphelele sesifunda sincishiswa ngokuqeda isidingo sezintambo ezengeziwe nezixhumi. Lokhu kwehliswa kwesisindo kunenzuzo ikakhulukazi ezinhlelweni ezidinga izisetshenziswa ezingasindi neziphathwayo, ezifana nogesi wabathengi, amasistimu ezimoto, noma izimoto zasemoyeni ezingenamuntu (ama-UAV).

Ukonga isikhala:Imvelo ehlangene futhi eguquguqukayo yamasekhethi aqinile angakwazi ukonga isikhala kumishini kagesi. Lezi zisekhethi zingalolongwa noma zibunjwe ukuze zilingane nendawo etholakalayo, kusetshenziswe kahle indawo etholakalayo. Kuzinhlelo zokusebenza lapho usayizi kanye nesici sefomu kubaluleke kakhulu, ukuncipha kosayizi wesekethe kubalulekile.

Ukuthembeka Okuthuthukisiwe:Ngenxa yokuklama kwayo, amasekhethi aqinile-aguquguqukayo anokwethenjelwa ngokwemvelo kunama-PCB endabuko aqinile. Ukungabikho kwezixhumi kunciphisa ingozi yokuhluleka kokuxhumeka, kuyilapho izinto eziguquguqukayo ezisetshenziswa ekwakhiweni kwesifunda zinikeza ukumelana okuhle kakhulu nokucindezeleka kwemishini, ukudlidliza kanye nokuhamba ngebhayisikili okushisayo. Lokhu kuqina okuthuthukisiwe nokuthembeka kwenza amasekhethi aqinile aguquguqukayo alungele izinhlelo zokusebenza ezinyakaziswa njalo noma ezichayeke endaweni enzima.

Ukonga izindleko:Ngenkathi izindleko zangaphambili zokukhiqiza amasekhethi aqinile-flex zingase zibe phezulu uma kuqhathaniswa nama-PCB endabuko aqinile, zingonga imali ngokuhamba kwesikhathi. Isidingo esincishisiwe sezixhumi, izintambo, nezingxenye zezengezo kusiza ukwenza lula inqubo yokukhiqiza kanye nezindleko eziphansi zokuhlanganisa. Ukwengeza, ukwethembeka okuthuthukisiwe nokuqina kwamasekhethi aqinile anganciphisa ukwehluleka kwenkundla kanye nezimangalo zewaranti, okuholela ekongeni kwezindleko ngaphezu komjikelezo wokuphila womkhiqizo.

Ukucatshangelwa kwezicelo zamandla aphezulu uma usebenzisa ama-rigid-flex circuits:

Uma usebenzisa ama-rigid-flex circuits kuzicelo zamandla aphezulu, kunezici ezimbalwa okufanele zicatshangelwe:

Into yokuqala okufanele icatshangelwe ukuchithwa kokushisa. Izinhlelo zokusebenza zamandla aphezulu zikhiqiza ukushisa okuningi, okungaba nomthelela omubi ekusebenzeni nokuthembeka kwamasekhethi aguquguqukayo aqinile. Ngenxa yokuklama kwawo, ama-rigid-flex circuits ane-conductivity elinganiselwe ye-thermal ngakho-ke awafaneleki kangako izinhlelo zokusebenza ezidinga ukuchithwa kokushisa okuphumelelayo. Kubalulekile ukusebenzisa amasu okulawula ukushisa ukuze unciphise ukunqwabelana kokushisa noma ukuhlola ezinye izixazululo ezifana nokuhlanganisa osinki bokushisa ekwakhiweni.

Esinye isici esibalulekile amandla amanje okuthwala amasekhethi aqinile-flex. Izinhlelo zokusebenza zamandla aphezulu zidinga amandla okuphatha amanani amakhulu wamanje ngaphandle kokubangela ukwehla kwamandla kagesi noma eminye imiphumela emibi. Nakuba amasekhethi e-rigid-flex-flex ngokuvamile engakwazi ukuphatha ama-currents amaphakathi, amandla awo okuthwala amanje angase akhawulelwe uma kuqhathaniswa nama-PCB endabuko aqinile. Isilinganiso samandla esidingekayo kufanele sicatshangelwe ngokucophelela, futhi ukuhlolwa okuphelele kufanele kwenziwe ukuze kuqinisekiswe ukuthi isifunda esiguquguqukayo esikhethiwe singakwazi ukuphatha umthwalo wamanje olindelekile ngaphandle kokuwohloka noma ukwehluleka.

Futhi, ekusetshenzisweni kwamandla aphezulu, ukukhethwa kwezinto ezisetshenziselwa ukwakha ama-rigid-flex circuits kufanele kuhlolwe ngokucophelela. Ukunakwa ngokukhethekile kufanele kukhokhwe ekukhethweni kwezinto zokuqhuba kanye ne-insulating zokulandelela nezixhumi. Izicelo zamandla aphezulu zingaphansi kokucindezeleka okukhulu nezinga lokushisa, ngakho-ke ukukhetha izinto ezinokumelana nezinga lokushisa eliphezulu kanye nokuhamba kahle kukagesi kubalulekile ekugcineni ukusebenza kahle nokuthembeka.

Futhi, cabangela ukucindezelwa kwemishini nokudlidliza okungase kube nakho amasekhethi aqinile-flex ezinhlelweni zokusebenza zamandla aphezulu. Ukuvumelana nezimo kwamasekhethi kungenza ukuthi abe sengozini yokukhathala noma ukwehluleka ngokuhamba kwesikhathi. Umklamo oqinile wemishini, izakhiwo ezifanele zokusekela, nokuhlaziywa kwengcindezi kufanele kusetshenziselwe ukuqinisekisa ukuthi umjikelezo ungamelana nokucindezeleka komshini kanye nokudlidliza kohlelo lokusebenza.

Okokugcina, ukuhlolwa kufanele kwenziwe ukuze kuhlolwe ukusebenza nokuthembeka kwamasekhethi aqinile-flex kuzinhlelo zokusebenza zamandla aphezulu. Lokhu kuhlanganisa ukuhlola ukusebenza okushisayo, umthamo wamanje wokuthwala, ukuqina komshini kanye nanoma yimiphi eminye imingcele efanele. Ukuhlola okuphelele kuzosiza ukukhomba noma yibuphi ubuthakathaka obungase bube noma imikhawulo yesekethe ye-rigid-flex futhi kuvumele ukulungiswa okudingekayo ukuthi kwenziwe noma kusetshenziswe ezinye izixazululo.

Ezinye izindlela zezicelo zamandla aphezulu:

Kwezinye izimo lapho ukushabalala okushisayo noma amandla okuthwala amandla aphezulu kuyinto eyinhloko, enye isixazululo.

kungaba ukukhetha okufanele kakhulu.

Ezimeni lapho ukunqanyulwa kokushisa noma amandla aphezulu okuthwala kwamanje kubaluleke kakhulu, kuyatuseka ukuhlola ezinye izixazululo kunokuthembela kuphela kumasekhethi aguquguqukayo aqinile. Okunye okunganikeza ukusebenza okungcono nokuthembeka kwezinhlelo zokusebenza ezinezidingo zamandla ahlukahlukene i-PCB eqinile yendabuko enezinyathelo ezanele zokuphatha ukushisa.

Ama-PCB endabuko aqinile anokusebenza okuhle kakhulu kokushisayo ngenxa yesakhiwo nokusetshenziswa kwezinto ezifana nethusi. Ama-PCB aqinile avumela amasu okuphatha okushisayo ahlukahlukene ukuthi asetshenziswe, okuhlanganisa nokuthela ithusi noma izindiza zokusabalalisa ukushisa okuphumelelayo. I-Copper iyi-conductor enhle kakhulu yokushisa, ekhipha ukushisa ngokuphumelelayo futhi inciphisa ingozi yokushisa ngokweqile ekusetshenzisweni kwamandla aphezulu.

Ukuze kuthuthukiswe ukuphathwa kwe-thermal kuzinhlelo zokusebenza zamandla aphezulu, usinki wokushisa wangokwezifiso ungahlanganiswa ekwakhiweni. Amasinki okushisa aklanyelwe ukudonsa ukushisa kude nezingxenye futhi akukhiphe endaweni ezungezile, ukuvimbela ukushisa ngokweqile. Isiphephetha-moya esipholile singabuye sengezwe ukuze kuthuthukiswe ukugeleza komoya nokuthuthukisa ukupholisa. Ezimweni ezimbi kakhulu, amasistimu okupholisa uketshezi angasetshenziswa ukunikeza ukuphathwa okushisayo okukhulu. Izinhlelo zokusebenza zamandla aphezulu zingazuza ekusebenzeni okuthuthukisiwe nokuthembeka ngokukhetha i-PCB eqinile yendabuko enezinyathelo ezifanele zokuphatha okushisayo. Lezi zindlela ezihlukile zibhekana kangcono nezinkinga ezihlobene nokunqanyulwa kokushisa, okuvumela izingxenye ukuthi zisebenze ngaphakathi kwebanga lokushisa elilungile.

Kuyaphawuleka ukuthi ezinhlelweni zokusebenza zamandla aphezulu, ukukhetha phakathi kwamasekhethi aqinile-aguquguqukayo kanye nama-PCB endabuko aqinile kufanele kusekelwe ekuhlolweni okuphelele kwezidingo zephrojekthi, okuhlanganisa izidingo zamandla, izidingo ezishisayo, izithiyo zesikhala, nezinye izici ezifanele. Inketho ngayinye inezinzuzo zayo kanye nokulinganiselwa kwayo, futhi ukukhetha isisombululo esifanele kuncike kuhlelo lokusebenza oluthile oluseduze.

Isiphetho:

Nakuba ama-rigid-flex circuits enikeza izinzuzo eziningi, ukufaneleka kwawo kwezicelo zamandla aphezulu kuncike ezintweni ezimbalwa. Nakuba zingase zanele ekusetshenzisweni kwamandla aphansi ukuya kwamaphakathi, ukuhlola ngokucophelela nokucatshangelwa kokunqanyulwa kokushisa namandla okuthwala amanje kubalulekile ezidingweni zamandla aphezulu. Uma lawa mabhodi engase angabi inketho engcono kakhulu, ezinye izixazululo ezifana nama-PCB endabuko aqinile anokuphathwa okuthuthukisiwe okushisayo nezindlela zokupholisa kufanele zihlolwe. Njengoba ubuchwepheshe buqhubeka buthuthuka, ukuthuthukiswa okuqhubekayo ekwakhiweni kwesekethe eqinile-flex kanye nezinto zokwakha kungase kugcine kukwenze kulunge kakhulu ekusetshenzisweni kwamandla aphezulu. Hlala uthintana nochwepheshe onolwazi futhi wenze ukuhlola okuphelele ngaphambi kokwenza isinqumo sokugcina sokuthi ingabe isifunda esiqinile esivumelana ne-flex ifanele isicelo esithile samandla aphezulu. Ekugcineni, izinqumo kufanele zisekelwe ekuqondeni okuphelele kwezidingo zephrojekthi, okuhlanganisa izidingo zamandla, ukupholisa izidingo, nezinye izici ezifanele. Ngokucubungula lezi zici ngokucophelela futhi uhlole ezinye izixazululo, ungaqinisekisa ukukhetha okufanele kakhulu kohlelo lwakho lokusebenza lwamandla aphezulu.

I-Shenzhen Capel Technology Co., Ltd.isungule imboni yayo eqinile ye-pcb ngo-2009 futhi ingumkhiqizi we-Flex Rigid Pcb ochwepheshe. Iminyaka engu-15 yokuhlangenwe nakho kwephrojekthi ecebile, ukugeleza kwenqubo okuqinile, amakhono angcono kakhulu ezobuchwepheshe, imishini ethuthukisiwe ethuthukisiwe, uhlelo oluphelele lokulawula ikhwalithi, futhi uCapel unethimba lochwepheshe abaqeqeshiwe ukuhlinzeka amakhasimende omhlaba ngebhodi eliguquguqukayo elinembayo eliphezulu, eliqinile, i-hdi Rigid. I-Flex Pcb, i-Rigid Flex Pcb Fabrication, i-rigid-flex pcb assembly,i-fast turn rigid flex pcb,i-prototypes esheshayo yokuvula i-pcb.Izinsizakalo zethu zobuchwepheshe ezisabelayo zangaphambi kokuthengisa kanye nangemuva kokuthengisa kanye nokulethwa okufika ngesikhathi kuvumela amakhasimende ethu ukuthi abambe ngokushesha amathuba emakethe amaphrojekthi awo. .

Isikhathi sokuthumela: Aug-26-2023

Emuva