Kulokhu okuthunyelwe kwebhulogi, sizohlola ukufaneleka kwama-PCB aguquguqukayo ezimweni zokushisa okuphezulu futhi sikunikeze imininingwane yokukusiza wenze isinqumo unolwazi.

Uma kukhulunywa ngezinto zikagesi kanye nezingxenye zazo, esinye sezici ezibalulekile okufanele zicatshangelwe izinga lokushisa kwazo lokusebenza. Izimo ezihlukene zingase zilethe izinselele ezihlukene, futhi indawo enezinga lokushisa eliphezulu ingase idinge kakhulu.

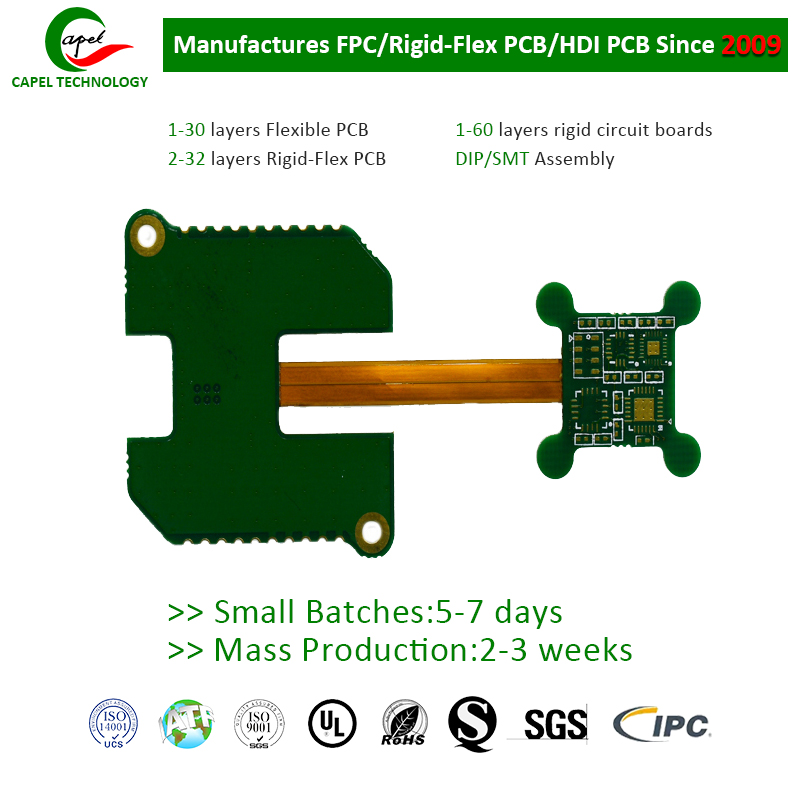

Eminyakeni yamuva nje, kuye kwaba nesithakazelo esikhulayo ekusetshenzisweni kwama-PCB aqinile-flex ezinhlelweni ezihlukahlukene zokusebenza. Lawa ma-PCB anikezela ngezinzuzo eziyingqayizivele njengokonga isikhala, ukwethembeka okukhulisiwe kanye nobuqotho besignali engcono. Kodwa-ke, ngaphambi kokuwafaka ekwakhiweni kwakho, kuyadingeka ukwazi ukuthi angakwazi yini ukumelana nezimo ezishisa kakhulu.

Qonda isakhiwo se-PCB esiqinile

Okokuqala, ake sixoxe kafushane ukuthi ayini ama-PCB aqinile futhi akhiwa kanjani.I-Rigid-flex PCBs amabhodi esekethe ayingxube ahlanganisa ama-substrates aqinile futhi aguquguqukayo abe yiyunithi eyodwa. Ahlanganisa izinzuzo zazo zombili izinhlobo zama-PCB, awenze abe nezinto ezihlukahlukene futhi akwazi ukuhlangabezana nezidingo zedizayini eziyinkimbinkimbi.

I-PCB evamile eqinile eguquguqukayo iqukethe izendlalelo eziningi zezinto eziqinile ezixhunywe izendlalelo eziguqukayo.Izendlalelo eziqinile zinikeza ukusimama kwesakhiwo, kuyilapho izingqimba eziguquguqukayo zivumela ibhodi ukugoba noma ukugoqa njengoba kudingeka. Lesi sakhiwo esiyingqayizivele senza ama-PCB asetshenziswe ezinhlelweni lapho isikhala sinqunyelwe noma ibhodi lidinga ukuhambisana nokuma okuthile.

Hlaziya imiphumela yamazinga okushisa aphezulu ku-PCB eguquguqukayo eqinile

Kunezici ezimbalwa ezisebenzayo lapho kuhlolwa ukufaneleka kwama-PCB aguquguqukayo ukuze asetshenziswe ezindaweni ezinezinga lokushisa eliphezulu.Ukucatshangelwa okubaluleke kakhulu umphumela wokushisa ezintweni ezisetshenziswa ekwakhiweni kwe-PCB.

Izendlalelo eziqinile zamabhodi e-rigid-flex ngokuvamile enziwa ngezinto ezifana ne-FR-4, ezaziwa ngokuzinza kwazo okushisayo kanye nokuncipha komlilo.Lezi zinto zingakwazi ukumelana namazinga okushisa afinyelela ku-130-140°C. Nokho, ungqimba oluguquguqukayo lwe-PCB ngokuvamile lwenziwa nge-polyimide noma izinto ezifanayo, ezinokumelana nokushisa okuphansi.

Izinto ze-Polyimide ezivame ukusetshenziswa kuma-PCB avumelana nezimo zingamelana nezinga lokushisa elifinyelela ku-250-300°C.Kodwa-ke, ukuchayeka isikhathi eside kumazinga okushisa anjalo aphezulu kungabangela ukuwohloka kwezinto, kunciphise impilo yonke kanye nokusebenza kwe-PCB. Ngakho-ke, izidingo ezithile zokushisa zezicelo zokushisa okuphezulu kufanele zicatshangelwe futhi kukhethwe izinto ezifanele ngokufanele.

Amasu Okunciphisa Izimo Zezinga Lokushisa Eziphakeme ebhodi lesifunda eliphrintiwe eliqinile

Nakuba ama-PCB aguquguqukayo angase abe nemikhawulo ezindaweni ezishisa kakhulu, akhona amasu amaningana okunciphisa imiphumela nokuthuthukisa ukusebenza kwawo.

1. Ukukhetha okubalulekile:Ukukhetha izinto ezinokumelana nokushisa okuphezulu kongqimba oluguquguqukayo kungathuthukisa kakhulu ukumelana nezinga lokushisa kwe-PCB. Izinto ze-Polyimide ezinezakhiwo ezithuthukisiwe ezishisayo, ezifana ne-Tg ephezulu (izinga lokushisa lokushintsha kwengilazi), zingasetshenziswa engxenyeni eguquguqukayo ukuze kukhuliswe ikhono le-PCB lokumelana nezinga lokushisa eliphezulu.

2. Isisindo sethusi nobubanzi bokulandelela:Ukwenyusa isisindo sethusi kanye nobubanzi bokulandelela ku-PCB kusiza ukuqeda ukushisa ngempumelelo kakhulu, ngaleyo ndlela kunciphisa ubungozi bokushisa okweqile kwendawo. Ukulandelela ithusi eliwugqinsi nezendlalelo zethusi ezinzima kakhulu, kanye nezingxenye eziphambanayo zekhondatha ezinkudlwana, zithuthukisa ikhono lebhodi lokuqeda ukushisa.

3. Ubuchwepheshe bokuphatha okushisayo:Ukusetshenziswa kobuchwepheshe obusebenzayo bokulawula okushisayo, okufana namasinki okushisa, izimbobo zokulahla ukushisa, nezindlela zokupholisa, kungasiza ukugcina izinga lokushisa elimaphakathi le-PCB lingaphakathi kwebanga elamukelekayo. Lobu buchwepheshe busiza ukuqondisa ukushisa kude nezingxenye ezibalulekile futhi kuvimbele ukulimala.

4. Ukuhlola nokuqinisekisa:Izinqubo eziqinile zokuhlola nokuqinisekisa kufanele zenziwe ukuze kuqinisekiswe ukuthi ama-PCB aqinile angakwazi ukumelana nezimo ezithile zezinga lokushisa eliphezulu. Ukuhlolwa kokuhamba ngebhayisikili okushisayo, amamodeli okulingisa, nesofthiwe yokuhlaziya ukufudumala kunganikeza imininingwane ebalulekile ekusebenzeni okushisayo kwe-PCB futhi kusize ukukhomba izindawo ezingaba nokukhathazeka.

5. Ubuchwepheshe bomhlinzeki:Kubalulekile ukukhetha umkhiqizi we-PCB onokwethenjelwa, onolwazi ngezinhlelo zokusebenza ezisezingeni eliphezulu. Umhlinzeki onolwazi angakuqondisa kunqubo yokukhetha impahla, anikeze izincomo ngamasu okunciphisa, futhi alethe ama-PCB ekhwalithi ephezulu aqinile ahlangabezana nezidingo zakho ezithile.

Ekuphetheni

Nakuba ama-PCB aqinile aguquguqukayo enikeza izinzuzo eziningi mayelana nokonga isikhala nokuthembeka, ukufaneleka kwawo endaweni enezinga lokushisa eliphezulu kuncike ekucatshangelweni ngokucophelela kwezici ezihlukahlukene.Ukuqonda imiphumela yokushisa ezintweni ezisetshenziswayo, ukusebenzisa amasu okunciphisa afanelekile, kanye nokusebenza nabahlinzeki abanolwazi kuyizinyathelo ezibalulekile ekuqinisekiseni ukuqaliswa okuphumelelayo kwe-PCB eguquguqukayo ezisetshenziswayo ezisezingeni eliphezulu.

Ngakho-ke, ingabe amabhodi aqinile-flex angasetshenziswa ezindaweni ezinezinga lokushisa eliphezulu? Impendulo ilele ekuhloleni ngokucophelela izidingo zakho zokushisa okuphezulu, idizayini efanele kanye nokukhetha kwempahla, kanye nokusetshenziswa kwamasu okuphatha okushisayo asebenzayo.Ngokucabangela lezi zici, ungenza isinqumo unolwazi futhi usebenzise izinzuzo ezinikezwa yi-rigid-flex PCBs kuyilapho uqinisekisa ukwethembeka kwemishini yakho ye-elekthronikhi ezindaweni ezinezinga lokushisa eliphezulu.

Isikhathi sokuthumela: Sep-16-2023

Emuva