Amabhodi esekethe aphrintiwe (ama-PCB) ayizingxenye ezibalulekile kumishini kagesi, futhi amabhodi esekethe aphrintiwe aqinile asetshenziswa kabanzi ukuze aqine futhi aguquguquke. Nokho, ngokuhamba kwesikhathi, lawa ma-PCB angalimala futhi adinge ukulungiswa.Lapha sizongena esihlokweni sokulungisa ama-PCB aqinile aguquguqukayo awonakele, sihlole izinhlobo ezivamile zomonakalo okungenzeka, sihlole izindlela zokulungisa ezihlukahlukene, futhi sigqamise izici ezibalulekile okufanele zicatshangelwe lapho ulungisa ngempumelelo i-PCB.Ngokuqonda amathuba namasu ahilelekile, ungakwazi ukuxazulula ngempumelelo umonakalo we-PCB futhi ubuyisele ukusebenza kumishini kagesi.

Ukuqonda amabhodi e-rigid-flex:

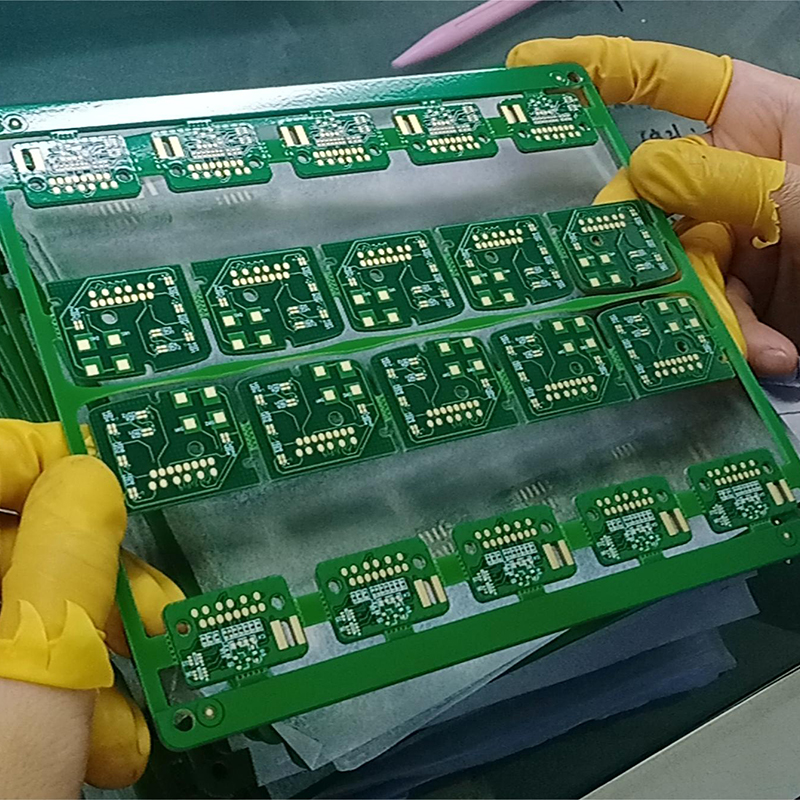

Ngaphambi kokungena ezindleleni zokulungisa i-PCB eyonakele eqinile, ake siqonde ukuthi ziyini.Ibhodi eliqinile eliguquguqukayo liwuhlobo lwebhodi elixubile elihlanganisa i-PCB eguquguqukayo ne-PCB eqinile. Lawa mabhodi aqukethe izendlalelo eziguquguqukayo ezixhumene nezigaba eziqinile, ezinikeza ukuguquguquka nokuzinza. Amabhodi aguquguqukayo avame ukusetshenziswa ezinhlelweni ezibandakanya izingqinamba zesikhala nemiklamo eyinkimbinkimbi.

Izinhlobo zomonakalo ezivamile kumabhodi we-pcb aqinile nezimo:

Amabhodi e-Rigid-flex angaba nezinhlobo ezihlukahlukene zokulimala futhi angadinga ukulungiswa noma ukushintshwa. Ezinye izinhlobo ezijwayelekile zomonakalo zihlanganisa:

a) Izintambo eziphukile:Imikhondo ku-PCB eguquguqukayo eqinile ingase yephuke ngenxa yengcindezi yemishini noma ingcindezi yangaphandle. Lokhu kungenzeka ngesikhathi sokuphatha noma ukuhlanganisa, noma ngenxa yokuguquguquka ngokweqile noma ukugoba kwebhodi. Intambo ephukile ingabangela ukuthi uxhumano lukagesi luphazamiseke, okuholela ekungasebenzi kahle noma ukungasebenzi kahle kwesekethe.

b) Ukwehluleka kwengxenye:Izingxenye ezidayiselwe i-PCB eguquguqukayo eqinile, njengama-resistors, ama-capacitor, noma amasekhethi ahlanganisiwe, angase alimale noma ahluleke ngokuhamba kwesikhathi. Lokhu kungase kube ngenxa yezinto ezifana nokuguga, ama-voltage spikes, ukushisa ngokweqile noma ukucindezeleka komshini. Uma ingxenye yehluleka, ukusebenza kwe-PCB kuba sengozini, okubangela izinkinga ngogesi okungeyakho.

c) Ukunciphisa:I-Delamination kwenzeka lapho izendlalelo ezingaphakathi kwe-PCB zihlukana noma zixebuka. Lokhu kungabangelwa izici ezihlukahlukene, okuhlanganisa ukuchayeka emazingeni okushisa adlulele ngesikhathi sokukhiqiza noma ukuphatha, ukugoba ngokweqile noma ukugoba ibhodi, noma ukuphatha okungafanele ngesikhathi sokuhlanganisa. I-Delamination yenza buthaka ubuqotho besakhiwo se-PCB, okuholela ekusebenzeni kukagesi okonakele kanye nokwehluleka kwesekethe okungaba khona.

d) Izixhumi ezilimele:Izixhumi, njengamasokhethi noma amapulaki, zisetshenziselwa ukusungula ukuxhumana kukagesi phakathi kwezingxenye ezihlukene zebhodi eliguquguqukayo eliqinile noma phakathi kwe-PCB nezinto zangaphandle. Lezi zixhumi zingalinyazwa ukushaqeka ngokomzimba, ukufakwa noma ukususwa okungafanele, noma ukuguga nokuklebhuka ngokuhamba kwesikhathi. Izixhumi ezilimele zingabangela ukuxhumeka kukagesi okungazinzile, ukwehluleka ngezikhathi ezithile, noma ukulahlekelwa okuphelele kokuxhumana phakathi kwezingxenye.

Izindlela zokulungisa amabhodi esekethe aqinile aqinile:

Ukulungisa futhi kuyindlela esebenzayo kwezinye izimo, nakuba ukushintshwa kwamaphaneli aguquguqukayo awonakele kungase kudingeke kwezinye izimo ezinzima. Nazi ezinye izindlela ezijwayelekile zokulungisa umonakalo wamabhodi aqinile-flex:

a) Ukulungisa i-Trace:Uma umkhondo ebhodini eliguquguqukayo eliqinile lonakalisiwe noma liphukile, lingalungiswa ngokusungula kabusha uxhumano lukagesi. Enye indlela iwukusebenzisa upende osetshenziswayo, osetshenziswa ngokuqondile endaweni eyonakele ukuze kuvalwe igebe. Enye inketho ukusebenzisa i-adhesive conductive, esetshenziswa endaweni eyonakele bese iphulukiswa ukuze kwakhiwe indlela yokuhambisa. Itheyiphu yethusi ene-adhesive-backed ingasetshenziswa futhi ukulungisa iminonjana ngokuyibeka phezu kwendawo eyonakele kanye nokuqinisekisa ukuthintana kahle kukagesi.

b) Ukushintshwa kwengxenye:Uma ingxenye ebhodini le-rigid-flex ihluleka noma yonakele, ingashintshwa ngayodwana. Lokhu kudinga ukuhlonza izingxenye ezithile ezidinga ukushintshwa nokuqinisekisa ukuthi ukumiselela okuhambisanayo kuyatholakala. Ingxenye engalungile ingachithwa ku-PCB ngensimbi yokunamathisela noma isiteshi sokugeleza kabusha, futhi ingxenye entsha ingathengiswa endaweni yayo.

c) Ukulungiswa Kwe-Delamination:Ukulungisa izendlalelo ezincishisiwe ku-PCB eguquguqukayo eqinile kungaba inselele. Kwezinye izimo, isixazululo sokunamathisela singasetshenziswa ukuze unamathisele kabusha izendlalelo ze-delaminated. Faka ngokucophelela i-adhesive endaweni ethintekile, uqiniseke ukuthi yenza ukuxhumana okufanele nazo zonke izendlalelo. Kodwa-ke, uma i-delamination inzima noma izendlalelo zilimele kakhulu, kungase kudingeke ukungenelela kochwepheshe noma ukushintshwa kwe-PCB.

d) Ukushintshwa kwesixhumi:Uma isixhumi ebhodini le-rigid-flex sonakalisiwe, singashintshwa ngokudiliza isixhumi esinephutha futhi sihlanganise esisha. Lokhu kudinga ukususwa ngokucophelela kwezingxenye ezinesici kusetshenziswa i-soldering iron noma i-reflow station. Isixhumi esisha sibe sesidayiswa endaweni efanayo, kuqinisekiswa ukuhleleka okufanele nokuthintana kukagesi.

Okucatshangelwayo Okubalulekile Ukulungisa Impumelelo yamabhodi we-pcb aqinile:

Lapho uzama ukulungisa ibhodi elimele elimele, kubalulekile ukucabangela lokhu okulandelayo:

a) Ikhono Nobungcweti:Ukulungiswa kwe-PCB kudinga ubuchwepheshe nokunemba. Uma ungenalwazi, kunconywa ukuthi uxhumane nochwepheshe noma ufune isiqondiso kuchwepheshe kulo mkhakha.

b) Izinsiza namathuluzi:Ukulungisa ama-PCB kudinga amathuluzi akhethekile kanye nemishini, njengezinsimbi zokunamathisela, ama-multimeter, izibuko zokukhulisa, njll., ukuze kuqinisekiswe ukulungiswa okunembile nokuphumelelayo.

c) Imibhalo Yedizayini:Amadokhumenti edizayini anembayo, okuhlanganisa izikimu nesakhiwo sebhodi, kubalulekile ukuze uqonde ukwakheka kwe-PCB nokuhlonza izindawo ezilimele.

d) Ukuhlola nokuqinisekisa:Ngemva kokulungisa ibhodi eliqinile-le-flex, inani elikhulu lokuhlolwa kufanele lenziwe ukuze kuqinisekiswe ukusebenza kahle kokulungisa. Lokhu kuhlanganisa ukuhlola ukuthi ugesi uxhumeke ngendlela efanele yini, ukusebenza kwawo kanye nokumelana nogesi.

e) Ukuhlanza nokuhlola:Kubalulekile ukuhlanza ibhodi eliqinile-flex kahle ngaphambi kokuqala inqubo yokubuyisela. Uthuli, ukungcola kanye nemfucumfucu kungaphazamisa inqubo yokulungisa futhi kuthinte umsebenzi we-PCB ekhandiwe. Ukuhlola ibhodi ngokucophelela kungasiza ekuboneni noma yimuphi omunye umonakalo noma izinkinga ezingase kudingeke zixazululwe ngesikhathi sokulungiswa.

f) Izinyathelo zokuphepha:Ukulungiswa kwe-PCB kubandakanya izingxenye ze-elekthronikhi kanye ne-soldering, okungase kube yingozi yokuphepha. Kubalulekile ukulandela izinyathelo zokuphepha ezifanele, njengokugqoka izinto zokuzivikela ezifana namagilavu nezibuko zokuphepha. Futhi, ukuqinisekisa ukuthi i-PCB ivaliwe futhi inqanyuliwe kunoma yimuphi umthombo wamandla kubalulekile ukugwema ukushaqeka kukagesi noma ukulimala kwengxenye.

g) Ikhwalithi yezinto zokulungisa:Izingxenye, ama-solder, ama-adhesives nezinye izinto zokulungisa ezisetshenziselwa inqubo yokulungisa zizoba sezingeni eliphezulu. Ukusebenzisa izinto ezingafanelekile kungase kubangele ukungalungiswa kahle noma umonakalo owengeziwe ebhodini eliguquguqukayo eliqinile. Ukuthola izinto zokubuyisela ezithembekile nezithembekile kubaluleke kakhulu.

h) Isikhathi Nesineke:Ukulungiswa kwe-PCB kudinga ukunakwa kwemininingwane nokubekezela. Ukusheshisa inqubo yokulungisa kungabangela amaphutha noma ukulungiswa okwanele. Thatha isikhathi esidingekayo ukuze uhlaziye ngokucophelela umonakalo, uhlele izinyathelo zokulungisa futhi uzenze ngokucophelela.

i) Amadokhumenti nokugcinwa kwamarekhodi:Kutuswa ukugcina imibhalo namarekhodi enqubo yokulungisa. Lokhu kuhlanganisa ukubhala izinyathelo ezithathiwe, izinto ezisetshenzisiwe, nanoma yiziphi izinguquko ezenziwe ngesikhathi sokubuyisela. Lawa madokhumenti awusizo ekusetshenzisweni kwesikhathi esizayo nanoma yiziphi izinkinga ezingase ziphakame kamuva.

j) Usizo lochwepheshe:Uma ibhodi elimele i-rigid-flex liyinkimbinkimbi noma umsebenzi wokulungisa ubonakala ungaphezu kwamakhono akho, kunconywa ukuba ufune usizo lochwepheshe. Ochwepheshe bokukhanda be-PCB abanolwazi nabanekhono banganikeza isiqondiso sochwepheshe futhi baqinisekise ukukhanda okuphumelelayo.

Ukulungisa amabhodi esekethe alimele aqinile aqinile kungenzeka kwezinye izimo.Impumelelo yokubuyisela incike ezingeni nohlobo lomonakalo kanye nokusetshenziswa okufanele kwezindlela zokubuyisela. Nokho, kufanele kuvunywe ukuthi kwezinye izimo umonakalo ungase ungalungiseki futhi kuzodingeka ukushintshwa okuphelele kwe-PCB. Ukuqinisekisa imiphumela engcono kakhulu, kunconywa ukufuna usizo lochwepheshe, ikakhulukazi ukulungiswa okuyinkimbinkimbi noma izimo zokungaqiniseki. Ukucabangela lezi zici kuzosiza ukufeza imiphumela esebenza kahle kakhulu futhi enokwethenjelwa yokulungisa amaphaneli e-rigid-flex.I-Shenzhen Capel Technology Co., Ltd.isungule imboni yayo eqinile ye-pcb ngo-2009 futhi ingumkhiqizi we-Flex Rigid Pcb ochwepheshe. Iminyaka engu-15 yokuhlangenwe nakho kwephrojekthi ecebile, ukugeleza kwenqubo okuqinile, amakhono obuchwepheshe asezingeni eliphezulu, okokusebenza okuzenzakalelayo okuthuthukisiwe, uhlelo oluphelele lokulawula ikhwalithi, futhi uCapel unethimba lochwepheshe lochwepheshe ukuze anikeze amakhasimende omhlaba ukunemba okuphezulu, izinga eliphezulu le-1-32 layer rigid flex. ibhodi, hdi Rigid Flex Pcb, Rigid Flex Pcb Fabrication, rigid-flex pcb assembly, fast turn rigid flex pcb, ukujika okusheshayo pcb prototypes.Izinsizakalo zethu zobuchwepheshe ezisabelayo zangaphambi kokuthengisa kanye nangemuva kokuthengisa kanye nokulethwa okufika ngesikhathi kwenza amakhasimende ethu abambe ngokushesha amathuba emakethe amaphrojekthi awo.

Isikhathi sokuthumela: Aug-28-2023

Emuva