I-Automotive electronics printed circuit board (PCBs) idlala indima ebalulekile ekusebenzeni kwezimoto ezithuthukile zanamuhla. Kusukela ekulawuleni amasistimu enjini nezibonisi ze-infotainment kuya ekuphatheni izici zokuphepha namandla okushayela ngokuzenzakalelayo, lawa ma-PCB adinga ukuklama okucophelelayo nezinqubo zokukhiqiza ukuze kuqinisekiswe ukusebenza okuphelele nokwethembeka.Kulesi sihloko, sizongena ohambweni oluyinkimbinkimbi lwama-PCB we-automotive electronics, sihlola izinyathelo ezibalulekile ezihilelekile kusukela kusigaba sokuqala sokuklama kuze kufike ekukhiqizeni.

1.Ukuqonda i-PCB ye-automotive electronic:

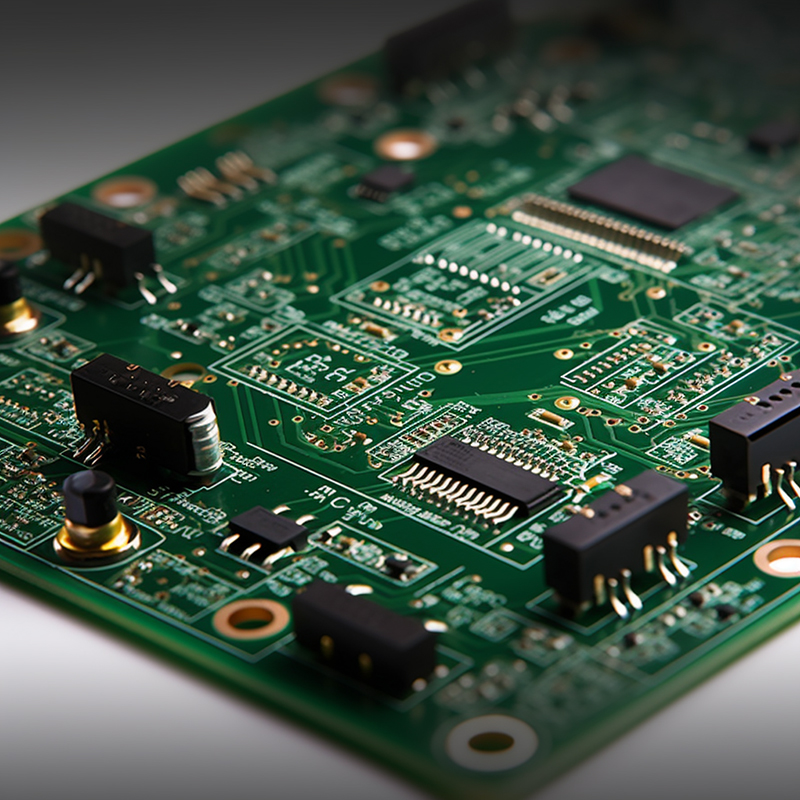

I-Automotive electronics PCB noma ibhodi lesifunda eliphrintiwe liyingxenye ebalulekile yezimoto zesimanje. Banomthwalo wemfanelo wokuhlinzeka ngoxhumo lukagesi nokusekelwa kwamasistimu kagesi ahlukahlukene emotweni, njengamayunithi okulawula injini, amasistimu e-infotainment, izinzwa, njll.Isici esiyinhloko sama-PCB kagesi wezimoto amandla awo okumelana nesimo esinzima sezimoto. Izimoto zingaphansi kokushintsha kwezinga lokushisa okwedlulele, ukudlidliza kanye nomsindo kagesi. Ngakho-ke, lawa ma-PCB adinga ukuhlala isikhathi eside kakhulu futhi athembeke ukuze kuqinisekiswe ukusebenza kahle nokuphepha. Ama-PCB we-Automotive electronics ngokuvamile aklanywa kusetshenziswa isofthiwe ekhethekile evumela onjiniyela ukuthi bakhe izakhiwo ezihlangabezana nezidingo ezithile zomkhakha wezimoto. Lezi zidingo zihlanganisa izici ezifana nosayizi, isisindo, ukusetshenziswa kwamandla, nokuhambisana kukagesi nezinye izingxenye. Inqubo yokukhiqiza yama-PCB kagesi wezimoto ibandakanya izinyathelo eziningi. Isakhiwo se-PCB siklanywe kuqala futhi silingiswe kahle futhi sahlolwa ukuze kuqinisekiswe ukuthi umklamo uhlangabezana nokucaciswa okudingekayo. Umklamo ube usudluliselwa ku-PCB ebonakalayo kusetshenziswa amasu anjengokuqopha noma ukufaka impahla yokuqhuba ku-substrate ye-PCB. Uma kubhekwa inkimbinkimbi yama-PCB e-automotive electronic, izingxenye ezengeziwe ezifana nezimbangi, ama-capacitor, namasekhethi ahlanganisiwe ngokuvamile afakwa ku-PCB ukuze kuqedelwe isekethe ye-elekthronikhi. Lezi zingxenye zivame ukugxunyekwa phezulu ku-PCB kusetshenziswa imishini yokubeka ezenzakalelayo. Ukunakwa okukhethekile kukhokhwa kwinqubo ye-welding ukuze kuqinisekiswe uxhumano olufanele nokuqina. Uma kubhekwa ukubaluleka kwezinhlelo zikagesi zezimoto, ukulawulwa kwekhwalithi kubalulekile embonini yezimoto. Ngakho-ke, ama-PCB e-elekthronikhi ezimoto ahlolwa kanzima futhi ahlolwe ukuze kuqinisekiswe ukuthi ayahlangabezana namazinga adingekayo. Lokhu kuhlanganisa ukuhlolwa kukagesi, ukuhamba ngebhayisikili okushisayo, ukuhlola ukudlidliza nokuhlolwa kwemvelo ukuze kuqinisekiswe ukwethembeka nokuqina kwe-PCB ngaphansi kwezimo ezihlukahlukene.

2.Inqubo ye-Automotive electronic PCB design:

Inqubo ye-automotive electronics PCB design ibandakanya izinyathelo ezimbalwa ezibalulekile zokuqinisekisa ukwethembeka, ukusebenza, kanye nokusebenza komkhiqizo wokugcina.

2.1 Idizayini yeskimu: Isinyathelo sokuqala enqubweni yokuklama ukwakheka kweskimu.Kulesi sinyathelo, onjiniyela bachaza ukuxhumana kukagesi phakathi kwezingxenye ngazinye ngokusekelwe ekusebenzeni okudingekile kwe-PCB. Lokhu kuhlanganisa ukudala umdwebo wohlelo olumele isekethe ye-PCB, okuhlanganisa ukuxhumana, izingxenye, nokuhlobana kwazo. Phakathi nalesi sigaba, onjiniyela bacabangela izinto ezifana nezidingo zamandla, izindlela zesignali, nokuhambisana namanye amasistimu emotweni.

2.2 Idizayini yesakhiwo se-PCB: Uma isikimu sesiqediwe, umklamo ungena esigabeni sokuklama isakhiwo se-PCB.Kulesi sinyathelo, onjiniyela baguqula isikimu sibe isakhiwo esibonakalayo se-PCB. Lokhu kuhlanganisa ukunquma usayizi, ukuma, kanye nendawo yezingxenye ebhodini lesifunda, kanye nomzila wamathrekhi kagesi. Idizayini yesakhiwo kufanele icabangele izici ezifana nobuqotho besignali, ukuphathwa kwe-thermal, ukuphazamiseka kozibuthe kagesi (EMI), kanye nokwenziwa. Ukunaka okukhethekile kukhokhwa ekubekweni kwengxenye ukuze kuthuthukiswe ukugeleza kwesignali nokunciphisa umsindo.

2.3 Ukukhethwa nokubekwa kwengxenye: Ngemva kokuqedwa kwesakhiwo sokuqala se-PCB, onjiniyela bayaqhubeka nokukhetha ingxenye kanye nokubeka.Lokhu kuhilela ukukhetha izingxenye ezifanele ngokusekelwe kuzimfuneko ezifana nokusebenza, ukusetshenziswa kwamandla, ukutholakala kanye nezindleko. Izinto ezifana nezingxenye zebanga lezimoto, izinga lokushisa kanye nokubekezelela ukudlidliza kubalulekile enqubweni yokukhetha. Izingxenye zibe sezibekwa ku-PCB ngokuya ngezinyathelo zazo kanye nezikhundla ezinqunywe ngesikhathi sesiteji sokuklama isakhiwo. Ukubekwa ngendlela efanele kanye nokuma kwezingxenye kubalulekile ukuze kuqinisekiswe ukuhlangana okuphumelelayo nokugeleza kwesignali efanele.

2.4 Ukuhlaziywa kobuqotho besignali: Ukuhlaziywa kobuqotho besignali kuyisinyathelo esibalulekile ekwakhiweni kwe-PCB ye-automotive electronics.Kubandakanya ukuhlola ikhwalithi nokuthembeka kwamasiginali njengoba asakazeka nge-PCB. Lokhu kuhlaziya kusiza ukukhomba izinkinga ezingaba khona njengokuncishiswa kwesignali, i-crosstalk, ukucabanga, nokuphazamiseka komsindo. Izinhlobonhlobo zamathuluzi okulingisa nawokuhlaziya asetshenziswa ukuze kuqinisekiswe ukuklama nokuthuthukisa isakhiwo ukuze kuqinisekiswe ubuqotho besignali. Abaklami bagxila ezintweni ezinjengobude bokulandelela, ukufanisa okubambezeleke, ubuqotho bamandla, kanye nemizila ye-impedance elawulwayo ukuze kuqinisekiswe ukudluliswa kwesignali okunembile nokungenamsindo.

Ukuhlaziywa kobuqotho besignali nakho kucabangela amasignali anesivinini esiphezulu kanye nezindawo ezibalulekile zamabhasi ezikhona ezinhlelweni zikagesi zezimoto. Njengoba ubuchwepheshe obuthuthukisiwe obufana ne-Ethernet, i-CAN ne-FlexRay busetshenziswa ngokwandayo ezimotweni, ukugcina ubuqotho besignali kuba inselele futhi kubalulekile.

3.Inqubo yokukhiqiza ye-PCB ye-Automotive electronic:

3.1 Ukukhetha impahla: Ukukhetha impahla ye-PCB ye-automotive electronics kubalulekile ekuqinisekiseni ukuqina, ukwethembeka kanye nokusebenza.Izinto ezisetshenziswayo kumele zikwazi ukumelana nezimo ezinzima zemvelo okuhlangatshezwana nazo ekusetshenzisweni kwezimoto, okuhlanganisa nokushintsha kwezinga lokushisa, ukudlidliza, umswakama nokuchayeka kwamakhemikhali. Izinto ezisetshenziswa kakhulu kuma-PCB e-automotive electronic zihlanganisa i-FR-4 (Flame Retardant-4) e-epoxy-based laminate, enokufakwa kahle kukagesi, amandla emishini kanye nokumelana nokushisa okuhle kakhulu. Ama-laminates okushisa aphezulu njenge-polyimide nawo asetshenziswa ezinhlelweni ezidinga ukuguquguquka okukhulu kwezinga lokushisa. Ukukhetha okubalulekile kufanele futhi kucabangele izidingo zesekethe yohlelo lokusebenza, njengamasiginali anesivinini esikhulu noma ama-electronics wamandla.

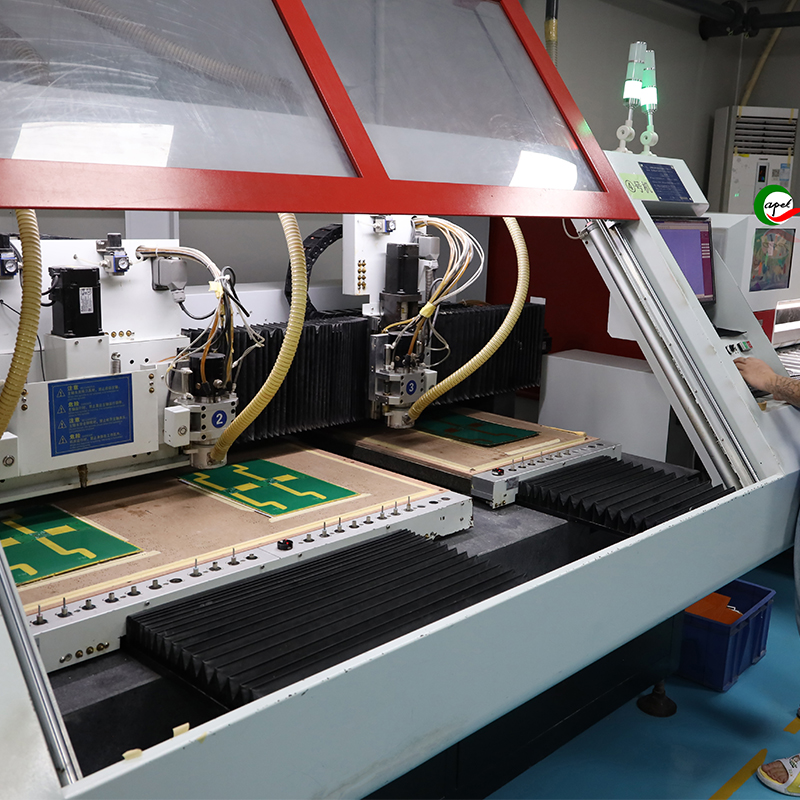

3.2 Ubuchwepheshe bokukhiqiza be-PCB: Ubuchwepheshe bokukhiqiza be-PCB bubandakanya izinqubo eziningi eziguqula imiklamo ibe amabhodi esekethe aphrintiwe.Inqubo yokukhiqiza ngokuvamile ihlanganisa izinyathelo ezilandelayo:

a) Ukudluliselwa Kwedizayini:Idizayini ye-PCB idluliselwa kusofthiwe ezinikele ekhiqiza amafayela omsebenzi wobuciko adingekayo ukuze kwenziwe.

b) Iphaneli:Ukuhlanganisa imiklamo eminingi ye-PCB ibe iphaneli eyodwa ukuze kuthuthukiswe ukusebenza kahle kokukhiqiza.

c) Isithombe:Gcoba ungqimba lwezinto ezizwela izithombe kuphaneli, futhi usebenzise ifayela lomsebenzi wobuciko ukuze uveze iphethini yesifunda edingekayo kuphaneli eboshwe.

d) Ukufaka:Ukufaka ngamakhemikhali izindawo eziveziwe zephaneli ukuze kukhishwe ithusi elingadingeki, kushiye imikhondo yesekethe oyifunayo.

e) Ukumba:Ukubhoboza izimbobo kuphaneli ukuze kufakwe umkhondo wengxenye kanye nama-vias okuxhumana phakathi kwezingqimba ezihlukene ze-PCB.

f) I-Electroplating:Ungqimba oluncane lwethusi lufakwa ku-electroplated kuphaneli ukuze kuthuthukiswe ukuqhutshwa kwemikhondo yesifunda futhi kunikeze indawo ebushelelezi yezinqubo ezilandelayo.

g) Isicelo Semaski Solder:Faka ungqimba lwemaski ye-solder ukuvikela iminonjana yethusi ku-oxidation futhi unikeze ukwahlukanisa phakathi kwamathrekhi aseduze. Imaski ye-Solder ibuye isize ukuhlinzeka ngokuhlukanisa okubonakalayo okucacile phakathi kwezingxenye ezahlukene kanye nokulandela.

h) Ukuphrinta isikrini:Sebenzisa inqubo yokuphrinta isikrini ukuze uphrinte amagama ezingxenye, amalogo nolunye ulwazi oludingekayo ku-PCB.

3.3 Lungiselela ungqimba lwethusi: Ngaphambi kokudala isifunda sohlelo lokusebenza, izingqimba zethusi ku-PCB zidinga ukulungiswa.Lokhu kuhlanganisa ukuhlanza indawo yethusi ukuze kukhishwe noma yikuphi ukungcola, ama-oxide noma ukungcola. Inqubo yokuhlanza ithuthukisa ukunamathela kwezinto ezithinta izithombe ezisetshenziswa enqubweni yokuthwebula izithombe. Izindlela ezihlukahlukene zokuhlanza zingasetshenziswa, okuhlanganisa ukukhuhla ngomshini, ukuhlanza amakhemikhali, nokuhlanza i-plasma.

3.4 Isekhethi yohlelo lokusebenza: Uma izendlalelo zethusi sezilungisiwe, isifunda sohlelo singadalwa ku-PCB.Lokhu kubandakanya ukusebenzisa inqubo yokuthwebula ukudlulisa iphethini yesekethe efunekayo ku-PCB. Ifayela lomsebenzi wobuciko elikhiqizwe idizayini ye-PCB lisetshenziswa njengereferensi yokudalula okokusebenza kwe-photosensitive ku-PCB ekukhanyeni kwe-UV. Le nqubo iqinisa izindawo eziveziwe, yenze imikhondo edingekayo yesifunda namaphedi.

I-3.5 PCB etching and drilling: Ngemva kokudala isifunda sohlelo, sebenzisa isixazululo samakhemikhali ukuze ukhiphe ithusi eliningi.I-photosensitive material isebenza njengemaski, ivikela imikhondo yesekethe edingekayo ekushubeni. Okulandelayo kuza inqubo yokubhoboza yokwenza izimbobo zezingxenye zokuhola kanye nama-vias ku-PCB. Izimbobo zibhojwa kusetshenziswa amathuluzi anembayo futhi izindawo zazo zinqunywa ngokusekelwe kumklamo we-PCB.

3.6 Ukufakwa kwemaski yokucwenga kanye ne-solder: Ngemuva kokuthi inqubo yokushumeka nokubhoboza isiqediwe, i-PCB iyafakwa ukuze kuthuthukiswe ukuqhutshwa kwemikhondo yesekethe.Gcoba ungqimba oluncane lwethusi endaweni yethusi eveziwe. Le nqubo yokucwenga isiza ukuqinisekisa ukuxhumana okuthembekile kukagesi futhi ikhulisa ukuqina kwe-PCB. Ngemuva kokucwenga, ungqimba lwemaski ye-solder lusetshenziswa ku-PCB. Imaski ye-solder ihlinzeka ngokufakwa futhi ivikela iminonjana yethusi kusuka ku-oxidation. Ngokuvamile kusetshenziswa ukuphrinta kwesikrini, futhi indawo lapho izingxenye zibekwe khona ishiywe ivuliwe ukuze ifakwe.

3.7 Ukuhlolwa nokuhlolwa kwe-PCB: Isinyathelo sokugcina senqubo yokukhiqiza ukuhlola nokuhlolwa kwe-PCB.Lokhu kubandakanya ukuhlola ukusebenza nekhwalithi ye-PCB. Ukuhlolwa okuhlukahlukene okunjengokuhlola ukuqhubeka, ukuhlolwa kokumelana ne-insulation, nokuhlolwa kokusebenza kukagesi kwenziwa ukuze kuqinisekiswe ukuthi i-PCB ihlangabezana nokucaciswa okudingekayo. Ukuhlola okubonakalayo kuyenziwa futhi ukuze kuhlolwe noma ikuphi ukonakala okufana nezikhindi, okuvulayo, ukungaqondi kahle, noma ukonakala kokubeka ingxenye.

Inqubo yokukhiqiza ye-PCB ye-automotive electronics ibandakanya uchungechunge lwezinyathelo ukusuka ekukhethweni kwezinto ezibonakalayo kuye ekuhlolweni nasekuhlolweni. Isinyathelo ngasinye sidlala indima ebalulekile ekuqinisekiseni ukwethembeka, ukusebenza kanye nokusebenza kwe-PCB yokugcina. Abakhiqizi kufanele bahambisane nezindinganiso zemboni kanye nezinqubo ezingcono kakhulu zokuqinisekisa ukuthi ama-PCB ahlangabezana nezidingo eziqinile zezinhlelo zokusebenza zezimoto.

4. Ukucatshangelwa okuqondene nemoto: kunezici ezithile eziqondene nemoto okufanele zibhekwe lapho kuklanywa futhi

ukukhiqiza ama-PCB ezimoto.

4.1 Ukukhishwa kokushisa nokuphathwa kokushisa: Ezimotweni, ama-PCB athintwa izimo zokushisa eziphakeme ngenxa yokushisa kwenjini nendawo ezungezile.Ngakho-ke, ukuchithwa kokushisa nokuphathwa kokushisa kuyizinto ezibalulekile ekwakhiweni kwe-PCB yezimoto. Izingxenye ezikhiqiza ukushisa njengama-electronics amandla, izilawuli ezincane, nezinzwa kufanele zibekwe ngendlela ehlelekile ku-PCB ukuze kuncishiswe ukugxila kokushisa. Osinki bokushisa nama-vents kuyatholakala ukuze kukhishwe ukushisa okusebenzayo. Ukwengeza, ukugeleza komoya okufanelekile kanye nezindlela zokupholisa kufanele zifakwe emiklamo yezimoto ukuvimbela ukwakheka kokushisa okudlulele futhi kuqinisekiswe ukwethembeka kwe-PCB nokuphila isikhathi eside.

4.2 Ukudlidliza kanye nokumelana nokushaqeka: Izimoto zisebenza ngaphansi kwezimo ezihlukahlukene zomgwaqo futhi zingaphansi kokuvevezela nokushaqeka okubangelwa amabhampa, imigodi kanye nezindawo ezimbi.Lokhu kudlidliza nokushaqeka kungathinta ukuqina nokuthembeka kwe-PCB. Ukuqinisekisa ukumelana nokudlidliza kanye nokushaqeka, ama-PCB asetshenziswa ezimotweni kufanele abe namandla ngomshini futhi afakwe ngokuvikelekile. Amasu okuklama afana nokusebenzisa amanye amajoyinti e-solder, ukuqinisa i-PCB nge-epoxy noma izinto zokuqinisa, nokukhetha ngokucophelela izingxenye nezixhumi ezimelana nokudlidliza kungasiza ekwehliseni imiphumela emibi yokudlidliza nokushaqeka.

4.3 Ukuhambelana kwe-Electromagnetic (EMC): Ukuphazanyiswa kwe-Electromagnetic (EMI) kanye nokuphazamiseka kwefrikhwensi yomsakazo (RFI) kungaphazamisa ukusebenza kwemishini ye-automotive electronic.Ukuxhumana okuseduze kwezingxenye ezihlukahlukene zemoto kuzokhiqiza izinkambu ze-electromagnetic eziphazamisana. Ukuqinisekisa i-EMC, idizayini ye-PCB kufanele ifake amasu afanelekile okuvikela, ukubeka phansi, kanye nokuhlunga ukuze kuncishiswe ukukhishwa kwezinto kanye nokuba sengozini kwamasignali kagesi. Amathini okuvikela, ama-conductor spacers, nezindlela ezifanele zesakhiwo se-PCB (njengokuhlukanisa imikhondo ebucayi ye-analog nedijithali) kungasiza ekunciphiseni imiphumela ye-EMI ne-RFI futhi kuqinisekiswe ukusebenza kahle kogesi wezimoto.

4.4 Amazinga okuphepha nokwethembeka: Izinto zikagesi zezimoto kufanele zihambisane nezindinganiso eziqinile zokuphepha nokwethembeka ukuze kuqinisekiswe ukuphepha kwabagibeli kanye nokusebenza kukonke kwemoto.Lawa mazinga afaka i-ISO 26262 yokuphepha okusebenzayo, echaza izidingo zokuphepha zezimoto zomgwaqo, kanye namazinga ahlukahlukene kazwelonke nawamazwe ngamazwe okuphepha kukagesi nokucatshangelwa kwemvelo (njenge-IEC 60068 yokuhlolwa kwemvelo). Abakhiqizi be-PCB kufanele baqonde futhi babambelele kulawa mazinga lapho beklama futhi bekhiqiza ama-PCB ezimoto. Ngaphezu kwalokho, ukuhlola ukuthembeka okufana nokuhamba ngebhayisikili kwezinga lokushisa, ukuhlolwa kokudlidliza, kanye nokuguga okusheshisiwe kufanele kwenziwe ukuze kuqinisekiswe ukuthi i-PCB ihlangabezana namazinga okuthembeka adingekayo ezinhlelo zokusebenza zezimoto.

Ngenxa yezimo zokushisa eziphezulu zemvelo yezimoto, ukuchithwa kokushisa nokuphathwa kokushisa kubalulekile. Ukudlidliza nokumelana nokushaqeka kubalulekile ukuze kuqinisekiswe ukuthi i-PCB ingakwazi ukumelana nezimo zomgwaqo ezinzima. Ukuhambisana kwe-electromagnetic kubalulekile ekunciphiseni ukuphazamiseka phakathi kwemishini ehlukahlukene yezimoto zikagesi. Ukwengeza, ukunamathela ezindinganisweni zokuphepha nokuthembeka kubalulekile ekuqinisekiseni ukuphepha nokusebenza kahle kwemoto yakho. Ngokuxazulula lezi zinkinga, abakhiqizi be-PCB bangakhiqiza ama-PCB ekhwalithi ephezulu ahlangabezana nezidingo ezithile zemboni yezimoto.

I-5.I-Automotive electronic PCB ukuhlanganisa nokuhlanganiswa:

Ukuhlanganiswa nokuhlanganiswa kwe-PCB ye-automotive electronics kuhilela izigaba ezihlukahlukene ezihlanganisa ukuthengwa kwezingxenye, ukuhlanganiswa kobuchwepheshe be-surface mount, izindlela zokuhlanganisa ezizenzakalelayo nezindlela ezenziwa ngesandla, nokulawulwa kwekhwalithi nokuhlola. Isigaba ngasinye sisiza ukukhiqiza ama-PCB ekhwalithi ephezulu, athembekile ahlangabezana nezidingo eziqinile zezinhlelo zokusebenza zezimoto. Abakhiqizi kufanele balandele izinqubo eziqinile kanye namazinga ekhwalithi ukuze baqinisekise ukusebenza nokuphila isikhathi eside kwalezi zingxenye ze-elekthronikhi ezimotweni.

5.1 Ukuthengwa kwezingxenye: Ukuthengwa kwezingxenye kuyisinyathelo esibalulekile enqubweni yokuhlanganisa ye-PCB ye-automotive electronics.Ithimba lokuthengwa kwempahla lisebenzisana eduze nabahlinzeki ukuze bathole futhi bathenge izingxenye ezidingekayo. Izingxenye ezikhethiwe kufanele zihlangabezane nezidingo ezicacisiwe zokusebenza, ukwethembeka, nokuhambisana nezinhlelo zokusebenza zezimoto. Inqubo yokuthenga ihlanganisa ukuhlonza abahlinzeki abathembekile, ukuqhathanisa amanani nezikhathi zokulethwa, nokuqinisekisa ukuthi izingxenye ziyiqiniso futhi zihlangabezana nezindinganiso zekhwalithi ezidingekayo. Amathimba okuthenga aphinde acabangele izici ezifana nokuphathwa kokuphelelwa yisikhathi ukuze kuqinisekiswe ukutholakala kwengxenye kuwo wonke umjikelezo wempilo womkhiqizo.

5.2 I-Surface Mount Technology (SMT): I-Surface Mount technology (SMT) iyindlela ekhethwayo yokuhlanganisa ama-PCB e-automotive electronics ngenxa yokusebenza kahle kwawo, ukunemba, nokuhambisana nezingxenye ezincane. I-SMT ibandakanya ukubeka izingxenye ngqo endaweni ye-PCB, ukususa isidingo somkhondo noma izikhonkwane.Izingxenye ze-SMT zifaka amadivayisi amancane, angasindi afana nezilawuli, ama-capacitor, amasekhethi ahlanganisiwe, nama-microcontrollers. Lezi zingxenye zibekwe ku-PCB kusetshenziswa umshini wokubeka ozenzakalelayo. Umshini ubeka ngokunembile izingxenye zokunamathisela i-solder ku-PCB, uqinisekisa ukuqondanisa okunembayo nokunciphisa ithuba lamaphutha. Inqubo ye-SMT inikeza izinzuzo ezimbalwa, okuhlanganisa ukuminyana kwezingxenye ezikhulayo, ukusebenza kahle kokukhiqiza okuthuthukisiwe, nokusebenza okuthuthukisiwe kukagesi. Ngaphezu kwalokho, i-SMT inika amandla ukuhlola nokuhlola okuzenzakalelayo, okuvumela ukukhiqizwa okusheshayo nokuthembekile.

5.3 Ukuhlanganiswa okuzenzakalelayo nokumataniswa: Ukuhlanganiswa kwama-PCB we-automotive electronics kungenziwa ngezindlela ezizenzakalelayo nezandla, kuye ngobunkimbinkimbi bebhodi kanye nezidingo ezithile zohlelo lokusebenza.Ukuhlanganiswa okuzenzakalelayo kuhilela ukusetshenziswa kwemishini ethuthukisiwe ukuhlanganisa ama-PCB ngokushesha nangokunembile. Imishini ezenzakalelayo, efana nezikhwezi ze-chip, amaphrinta e-solder paste, namahhavini agelezayo, asetshenziselwa ukubekwa kwengxenye, uhlelo lokusebenza lokunamathisela i-solder, kanye ne-reflow soldering. Ukuhlanganiswa okuzenzakalelayo kusebenza kahle kakhulu, kunciphisa isikhathi sokukhiqiza futhi kunciphisa amaphutha. Ukuhlanganisa okwenziwa ngesandla, ngakolunye uhlangothi, kuvame ukusetshenziselwa ukukhiqizwa kwevolumu ephansi noma lapho izingxenye ezithile zingafanelekile ukuhlanganisa okuzenzakalelayo. Ochwepheshe abanekhono basebenzisa amathuluzi akhethekile nezinto zokusebenza ukubeka ngokucophelela izingxenye ku-PCB. Ukuhlanganisa okwenziwa ngesandla kuvumela ukuguquguquka okukhulu nokwenza ngokwezifiso kunokuhlanganiswa okuzenzakalelayo, kodwa kuhamba kancane futhi kuthambekele kakhulu emaphutheni omuntu.

5.4 Ukulawula Ikhwalithi Nokuhlola: Ukulawula ikhwalithi nokuhlola kuyizinyathelo ezibalulekile ekuhlanganiseni nasekuhlanganisweni kwe-PCB ye-automotive electronics. Lezi zinqubo zisiza ukuqinisekisa ukuthi umkhiqizo wokugcina uhlangabezana namazinga adingekayo wekhwalithi nokusebenza.Ukulawulwa kwekhwalithi kuqala ngokuhlola izingxenye ezingenayo ukuze kuqinisekiswe ubuqiniso bazo nekhwalithi. Phakathi nenqubo yokuhlanganisa, ukuhlolwa kwenziwa ezigabeni ezehlukene ukuze kuhlonzwe futhi kulungiswe noma yiziphi izinkinga noma izinkinga. Ukuhlola okubonakalayo, ukuhlola okuzenzakalelayo kwe-optical inspection (AOI) kanye nokuhlolwa kwe-X-ray kuvame ukusetshenziswa ukuze kutholwe iziphambeko ezingaba khona njengamabhuloho athengiswayo, ukungaqondani kahle kwengxenye noma ukuxhumana okuvulekile.

Ngemva kokuhlanganisa, i-PCB idinga ukuhlolwa ngokusebenza ukuze kuqinisekiswe ukusebenza kwayo. Tizinqubo zokuhlola zingabandakanya ukuhlola amandla, ukuhlola ukusebenza, ukuhlolwa kwesekhethi, nokuhlolwa kwemvelo ukuze kuqinisekiswe ukusebenza, izici zikagesi, nokuthembeka kwe-PCB.

Ukulawulwa kwekhwalithi nokuhlola kuphinde kubandakanye ukulandeleka, lapho i-PCB ngayinye imakwe noma imakwe ngesihlonzi esiyingqayizivele ukuze kulandelelwe umlando wayo wokukhiqiza nokuqinisekisa ukuziphendulela.Lokhu kuvumela abakhiqizi ukuthi bakhombe futhi balungise noma yiziphi izinkinga futhi kunikeza idatha ebalulekile yokuthuthukisa okuqhubekayo.

6.I-Automotive electronic PCB Amathrendi nezinselelo zesikhathi esizayo:Ikusasa lama-PCB e-automotive electronics lizothonywa

izitayela ezifana ne-miniaturization, ukwanda kobunzima, ukuhlanganiswa kobuchwepheshe obuthuthukisiwe, kanye nesidingo sokuthuthukiswa

izinqubo zokukhiqiza.

6.1 I-Miniaturization kanye nobunkimbinkimbi obukhulayo: Enye yezinto ezihamba phambili ezibalulekile kuma-PCB we-automotive electronics ukucindezela okuqhubekayo kokusebenza okuncane nokuba yinkimbinkimbi.Njengoba izimoto ziba zithuthuke kakhulu futhi zihlome ngezinhlelo ezahlukene ze-elekthronikhi, isidingo sama-PCB amancane naminyene siyaqhubeka nokwanda. Lokhu kulungiswa okuncane kubangela izinselele ekubekweni kwengxenye, umzila, ukushabalala kokushisa, nokuthembeka. Abaklami be-PCB nabakhiqizi kumele bathole izixazululo ezintsha ukuze kuhlangatshezwane nezinto ezinciphayo zamafomu kuyilapho kugcinwa ukusebenza nokuqina kwe-PCB.

6.2 Ukuhlanganiswa kobuchwepheshe obuphambili: Imboni yezimoto ibona intuthuko esheshayo kwezobuchwepheshe, okuhlanganisa nokuhlanganiswa kobuchwepheshe obuphambili ezimotweni.Ama-PCB adlala indima ebalulekile ekunikeni lobu buchwepheshe amandla, njengezinhlelo ezithuthukisiwe zokusiza abashayeli (ADAS), amasistimu ezimoto zikagesi, izixazululo zokuxhuma nezici zokushayela ezizimele. Lobu buchwepheshe obuthuthukisiwe budinga ama-PCB angasekela isivinini esikhulu, asingathe ukucutshungulwa kwedatha okuyinkimbinkimbi, futhi aqinisekise ukuxhumana okuthembekile phakathi kwezingxenye ezihlukahlukene nezinhlelo. Ukuklama nokukhiqiza ama-PCB ahlangabezana nalezi zidingo kuyinselelo enkulu embonini.

6.3 Inqubo yokukhiqiza idinga ukuqiniswa: Njengoba isidingo sama-PCB e-automotive electronics siqhubeka sikhula, abakhiqizi babhekene nenselele yokuthuthukisa izinqubo zokukhiqiza ukuze bahlangabezane nenani eliphezulu lokukhiqiza kuyilapho begcina amazinga aphezulu.Ukwenza lula izinqubo zokukhiqiza, ukwenza ngcono ukusebenza kahle, ukunciphisa izikhathi zomjikelezo kanye nokunciphisa amaphutha yizindawo lapho abakhiqizi kudingeka bagxilise khona imizamo yabo. Ukusetshenziswa kobuchwepheshe obuthuthukisiwe bokukhiqiza, obufana nokuhlanganisa okuzenzakalelayo, amarobhothi kanye nezinhlelo zokuhlola ezithuthukisiwe, kusiza ukuthuthukisa ukusebenza kahle nokunemba kwenqubo yokukhiqiza. Ukwamukela imiqondo ye-Industry 4.0 efana ne-inthanethi Yezinto (IoT) kanye nokuhlaziywa kwedatha kunganikeza imininingwane ebalulekile ekuthuthukisweni kwenqubo nokugcinwa kokuqagela, ngaleyo ndlela kwandise umkhiqizo kanye nokuphumayo.

7. Umkhiqizi owaziwayo webhodi lesifunda sezimoto:

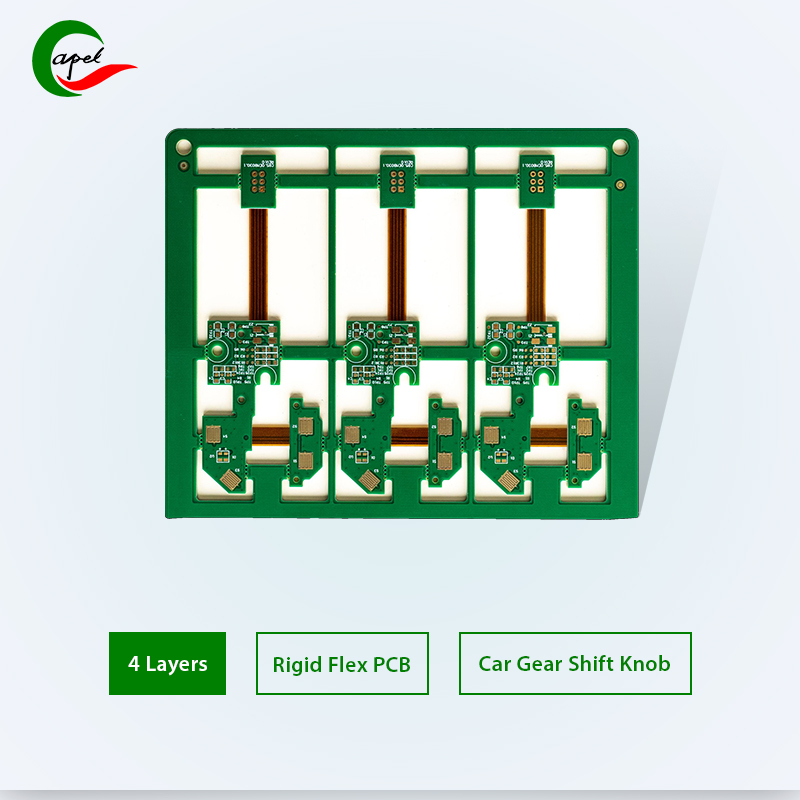

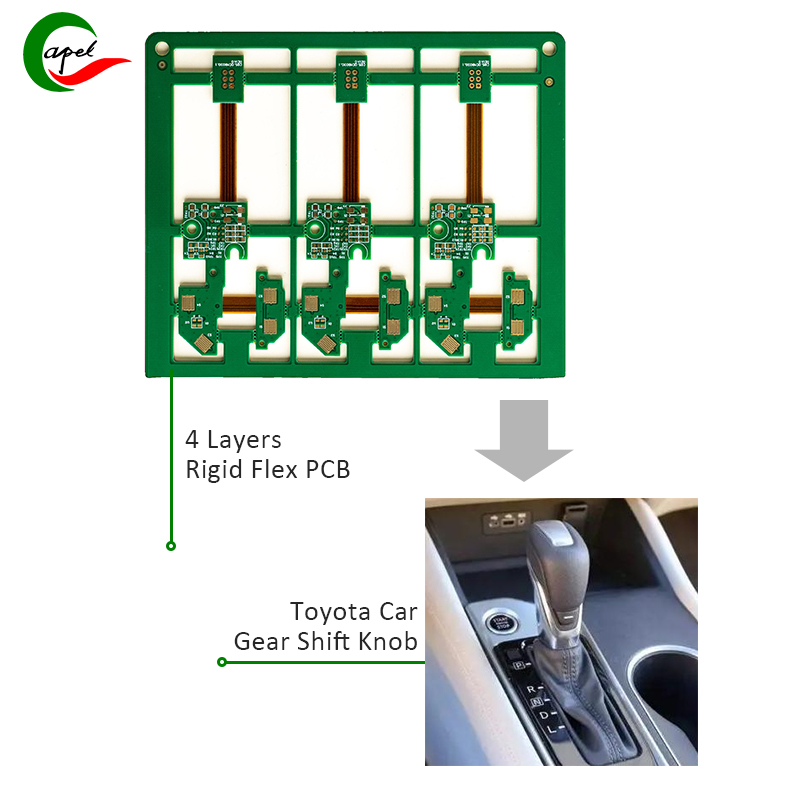

I-Shenzhen Capel Technology Co., Ltd. yasungula imboni yebhodi lesifunda ngo-2009 futhi yaqala ukuthuthukisa nokwenza amabhodi esekethe aguquguqukayo, amabhodi ayingxube, namabhodi aqinile. Kule minyaka engu-15 edlule, siqede ngempumelelo amashumi ezinkulungwane zamaphrojekthi webhodi lesifunda sezimoto kumakhasimende, sanqwabelana nolwazi olucebile embonini yezimoto, futhi sanikeza amakhasimende izixazululo eziphephile nezithembekile. Onjiniyela abaqeqeshiwe bakwa-Capel namaqembu e-R&D angochwepheshe ongabathemba!

Ngokufigqiwe,inqubo yokukhiqiza i-PCB ye-automotive electronics iwumsebenzi oyinkimbinkimbi futhi ocophelelayo odinga ukubambisana okuseduze phakathi konjiniyela, abaklami, nabakhiqizi. Izidingo eziqinile zemboni yezimoto zidinga ama-PCB ekhwalithi ephezulu, athembekile futhi aphephile. Njengoba ubuchwepheshe buqhubeka nokuthuthuka, ama-PCB e-automotive electronics azodinga ukuhlangabezana nesidingo esikhulayo semisebenzi eyinkimbinkimbi neyinkimbinkimbi. Ukuze uhlale ngaphambi kwalo mkhakha ovela ngokushesha, abakhiqizi be-PCB kufanele bahambisane namathrendi akamuva. Kudingeka batshale imali ezinqubweni zokukhiqiza ezithuthukile kanye nemishini ukuze baqinisekise ukukhiqizwa kwama-PCB asezingeni eliphezulu. Ukusebenzisa izinqubo zekhwalithi ephezulu akugcini nje ngokuthuthukisa ulwazi lokushayela, kodwa futhi kubeka phambili ukuphepha nokunemba.

Isikhathi sokuthumela: Sep-11-2023

Emuva