Izingxenye zembobo, njengoba negama liphakamisa, zinemikhondo noma izikhonkwane ezishuthekwa ngembobo ku-PCB bese zidayiswa kuphedi ngakolunye uhlangothi. Lezi zingxenye zisetshenziswa kabanzi embonini ngenxa yokuthembeka kwazo kanye nokulungisa kalula. Ngakho-ke, ingabe ama-PCB aqinile angakwazi ukuthwala izingxenye zembobo? Ake sijule kulesi sihloko ukuze sithole.Kodwa-ke, umbuzo ojwayelekile ophakamayo uma kucutshungulwa ukusetshenziswa kwama-PCB aqinile-flex ukuhambisana kwawo nezingxenye zembobo.

Ngamafuphi, impendulo ithi yebo, ama-PCB aqinile ahambisana nezingxenye zembobo. Kodwa-ke, ukucatshangelwa kokuklama okuthile kufanele kucatshangelwe ukuze kuqinisekiswe ukuhlanganiswa okuphumelelayo.

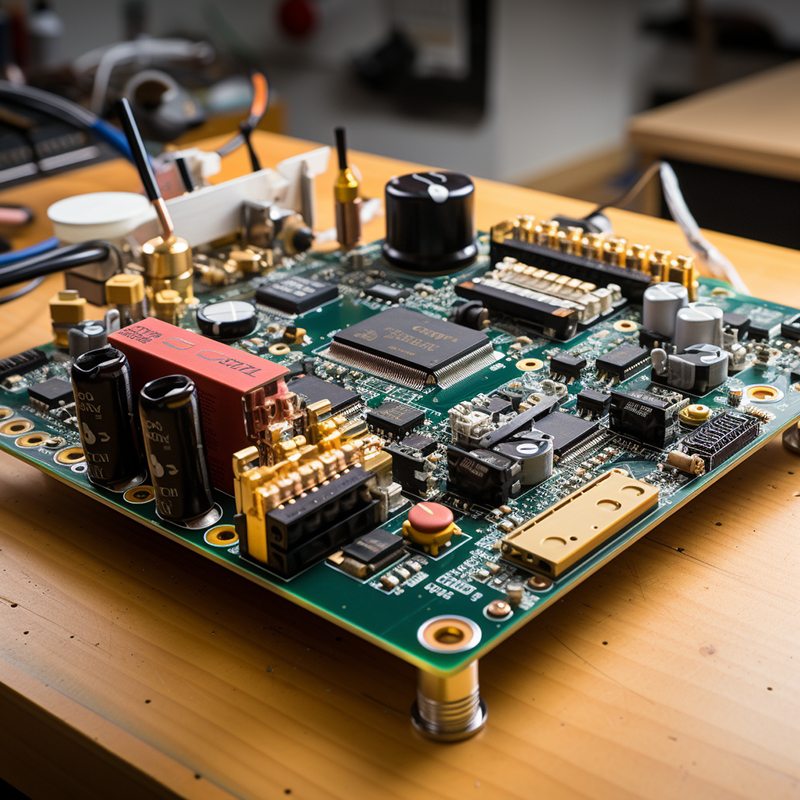

Esimweni sanamuhla sobuchwepheshe esithuthuka ngokushesha, isidingo semishini kagesi enikezela ngokusebenza okuphezulu ezintweni ezincane sekuyinsakavukela. Ngakho-ke, imboni yePrinted Circuit Board (PCB) iyaphoqeleka ukuthi isungule futhi ithuthukise izixazululo ezintsha ezithuthukile ukuze ihlangabezane nalezi zidingo. Isixazululo esisodwa ukwethulwa kwama-PCB aguquguqukayo, ahlanganisa ukuguquguquka kwama-PCB aguquguqukayo namandla nokuqina kwama-PCB aqinile.

I-Rigid-flex PCBs idumile ngabaklami nabakhiqizi ngekhono labo lokukhulisa ukuguquguquka kwedizayini ngenkathi behlisa usayizi nesisindo esiphelele.Asetshenziswa ezinhlelweni eziningi ezahlukahlukene, kufaka phakathi i-aerospace, idivayisi yezokwelapha, umthengi kagesi kanye nezimboni zezimoto.

Okunye okukhathazayo okuyinhloko lapho usebenzisa izingxenye ze- through-hole kuma-PCB aqinile-flex ukucindezeleka komshini okungase kusetshenziswe kumalungu e-solder ngesikhathi sokuhlanganisa noma ukusetshenziswa ensimini. I-PCB eguquguqukayo eqinile, njengoba igama liphakamisa, iqukethe izindawo eziqinile neziguquguqukayo ezixhumene ngokugqitshwa ngezimbobo noma izixhumi eziguquguqukayo.Izingxenye eziguquguqukayo zikhululekile ukugoba noma ukusonta i-PCB, kuyilapho izingxenye eziqinile zinikeza ukuzinza nokusekelwa emhlanganweni. Ukwamukela izingxenye zembobo, abaklami badinga ukukhetha ngokucophelela indawo yezimbobo futhi baqinisekise ukuthi zibekwe engxenyeni eqinile ye-PCB ukugwema ukucindezeleka ngokweqile kumajoyinti e-solder.

Okunye okucatshangelwayo okubalulekile wukusebenzisa izindawo okusetshenzwa kulengwa kuzo ezifanele izingxenye zembobo. Ngenxa yokuthi ama-PCB aqinile angakwazi ukugoba noma ukusonteka, kubalulekile ukunikeza ukwesekwa okwengeziwe ukuze kuvinjwe ukunyakaza okudlulele nokucindezeleka kumalunga e-solder.Ukuqinisa kungafinyelelwa ngokungeza izigxivizo noma amabakaki azungeze ingxenye yembobo ukuze kusabalaliswe ngokulinganayo ingcindezi.

Ukwengeza, abaklami kufanele banake ubukhulu kanye nokuma kwezingxenye ze- through-hole . Izimbobo kufanele zilinganiswe ngokufanele ukuze kuqinisekiswe ukulingana okuqinile, futhi izingxenye kufanele ziqondiswe ukuze kuncishiswe ubungozi bokuphazamiseka kwezingxenye eziguquguqukayo ze-PCB.

Kuhle futhi ukubalula ukuthi inqubekelaphambili kubuchwepheshe bokukhiqiza be-PCB yenze kwaba nokwenzeka ukukhiqiza ama-PCB aguquguqukayo kusetshenziswa ubuchwepheshe be-high-density interconnect (HDI).I-HDI inika amandla ingxenye encane yokwenza i-miniaturization kanye nokuminyana kwesifunda okwandisiwe, okwenza kube lula ukuhlanganisa izingxenye zembobo engxenyeni eguquguqukayo ye-PCB ngaphandle kokufaka engozini ukusebenza noma ukwethembeka.

Ngokufigqiwe, i-rigid-flex PCBs ingahambisana ngempela nezingxenye ze- through-hole uma ukucatshangelwa okuthile komklamo kucatshangelwa.Ngokukhetha ngokucophelela izindawo, ukuhlinzeka ngosekelo olwanele, nokusebenzisa ngokunenzuzo intuthuko kwezobuchwepheshe bokukhiqiza, abaklami bangahlanganisa ngempumelelo izingxenye zembobo kuma-PCB aguquguqukayo aqinile ngaphandle kokuyekethisa ukusebenza noma ukwethembeka. Njengoba ubuchwepheshe buqhubeka nokuthuthuka, ukusetshenziswa kwama-PCB aqinile-flex kulindeleke ukuthi kwande, kunikeze amathuba engeziwe emiklamo ye-elekthronikhi esebenza kahle.

Isikhathi sokuthumela: Sep-20-2023

Emuva