Kulesi sihloko esibanzi, singena emhlabeni wezitaki ze-PCB ezinezingqimba ezi-4, ezikuqondisa ngamasu okuklama angcono kakhulu nokucatshangelwa.

Isingeniso :

Emhlabeni wedizayini ye-PCB (ibhodi lesifunda eliphrintiwe), ukuzuza ukunqwabelana okufanelekile kubalulekile ukuze kuqinisekiswe ukusebenza okungaguquki nokusebenza okuthembekile. Ukuze kuhlangatshezwane nezidingo ezihlala zikhula zemishini yesimanje kagesi, njengesivinini esisheshayo, ukuminyana okuphezulu, nokuphazamiseka kwesignali encishisiwe, isitaki se-PCB esendlalelo esingu-4 esihlelwe kahle sibalulekile. Lesi sihloko sisebenza njengomhlahlandlela ophelele wokukusiza uqonde izici ezibalulekile nokucatshangelwa okuhilelekile ekuzuzeni isitaki se-PCB esendlalelo esi-4 esilungile. Ngakho-ke, ake singene sijule emhlabeni we-PCB stackup futhi sembule izimfihlo zomklamo oyimpumelelo!

okuqukethwe:

1. Qonda okuyisisekelo kokunqwabelaniswa kwe-PCB yezendlalelo ezi-4 :

- I-PCB Stackup: Iyini futhi kungani ibalulekile?

- Ukucatshangelwa okubalulekile kwedizayini yesitaki enezendlalelo ezi-4.

- Ukubaluleka kokuhlelwa kongqimba olufanele.

- Izingqimba zamasignali nokusabalalisa: izindima nezindawo.

- Izinto ezithinta ukukhethwa kwengqikithi yangaphakathi kanye nezinto zokulungiselela kusengaphambili.

Isitaki se-PCB:I-PCB stackup ibhekisela ekuhlelweni nasekucushweni kwezendlalelo ezihlukene ebhodini lesekethe eliphrintiwe. Kubandakanya ukubeka izendlalelo ze-conductive, insulating, kanye nesignali yokusabalalisa ngendlela ethile ukuze kuzuzwe ukusebenza kukagesi okufunayo kanye nokusebenza kwe-PCB. I-PCB stackup ibalulekile ngoba inquma ubuqotho besignali, ukusatshalaliswa kwamandla, ukuphathwa okushisayo kanye nokusebenza kukonke kwe-PCB.

Ukucatshangelwa Okubalulekile Kwedizayini Yesitaki Yezingqimba Ezi-4:

Lapho uklama isitaki se-PCB esendlalelo ezi-4, okunye okucatshangelwayo okubalulekile kufaka phakathi:

Ubuqotho besignali:

Ukubeka izendlalelo zesignali eduze komunye nomunye ngenkathi kugcinwa amandla nezindiza eziphansi ziseduze kuthuthukisa ubuqotho besignali ngokunciphisa i-impedance phakathi kokulandela isignali nezindiza zereferensi.

Ukusabalalisa Amandla Nomhlaba:

Ukusatshalaliswa ngendlela efanele kanye nokubekwa kwamandla kanye nezindiza eziphansi kubalulekile ekusabalaliseni kahle kwamandla kanye nokunciphisa umsindo. Kubalulekile ukunaka ukushuba kanye nesikhala phakathi kwamandla nezindiza eziphansi ukuze kuncishiswe i-impedance.

Ukuphathwa kokushisa:

Ukubekwa kwama-vias ashisayo kanye namasinki okushisa kanye nokusatshalaliswa kwezindiza ezishisayo kufanele kucatshangelwe ukuze kuqinisekiswe ukukhishwa okusebenzayo kokushisa nokuvimbela ukushisa ngokweqile.

Ukubekwa kwengxenye kanye nokusebenziseka:

Ukucatshangelwa ngokucophelela kufanele kunikezwe ukubekwa kwengxenye kanye nomzila ukuze kuqinisekiswe umzila wesignali olungile futhi ugweme ukuphazamiseka kwesignali.

Ukubaluleka Kohlelo Olufanele Lwesendlalelo:Ukuhlelwa kwesendlalelo kusitaki se-PCB kubalulekile ekugcineni ubuqotho besignali, ukunciphisa ukuphazamiseka kukagesi kagesi (EMI), nokuphatha ukusatshalaliswa kwamandla. Ukubekwa kahle kwesendlalelo kuqinisekisa i-impedance elawulwayo, kunciphisa i-crosstalk, futhi kuthuthukisa ukusebenza okuphelele komklamo we-PCB.

Izendlalelo zesignali nokusabalalisa:Amasignali ngokuvamile ahanjiswa ezendlalelo zesignali ezingaphezulu nangaphansi, kuyilapho izindiza zamandla nezaphansi zingaphakathi. Isendlalelo sokusabalalisa sisebenza njengamandla nendiza yaphansi futhi sinikeza indlela ephansi ye-impedance yamandla nokuxhumeka komhlaba, ukunciphisa ukwehla kwamandla kagesi kanye ne-EMI.

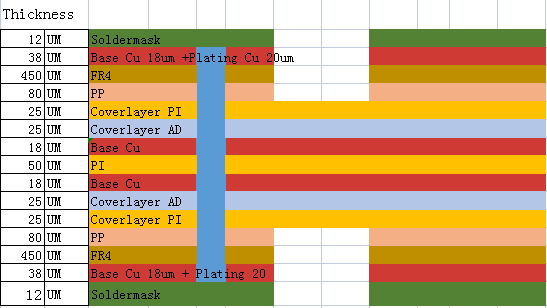

Izinto Ezithinta Ukukhethwa Kwezinto Okubalulekile Nokulungiselela Ukulungiselela:Ukukhethwa kwezinto ezibalulekile nezangaphambi kokulungiswa kwesitaki se-PCB kuncike ezintweni ezifana nezimfuneko zokusebenza kukagesi, ukucatshangelwa kokuphathwa kokushisa, ukwenziwa, kanye nezindleko. Ezinye izici ezibalulekile okufanele zicatshangelwe zifaka i-dielectric constant (Dk), i-dielectric factor (Df), izinga lokushisa lokushintsha kwengilazi (Tg), ukujiya, nokuhambisana nezinqubo zokukhiqiza ezifana ne-lamination kanye nokubhoboza. Ukukhetha ngokucophelela lezi zinto kuqinisekisa izici ezifiselekayo zikagesi nezemishini ze-PCB.

2. Amasu okuthola isitaki se-PCB yesendlalelo ezi-4:

- Ukubekwa kwengxenye ngokucophelela nokulandelela umzila ukuze uthole amandla asebenzayo nobuqotho besignali.

- Indima yezindiza eziphansi namandla ekwehliseni umsindo nasekukhuliseni ubuqotho besignali.

- Thola ukujiya okufanele kanye nokulingana kwe-dielectric kwesendlalelo ngasinye.

- Thatha ithuba lomzila olawulwayo we-impedance wemiklamo enesivinini esikhulu.

- Ukucatshangelwa kokushisa nokuphathwa kokushisa kuzitaki zezendlalelo eziningi.

Lawa masu asiza ukufeza isitaki se-PCB esendlalelo ezi-4 esilungile:

Ukubekwa kwengxenye ngokucophelela nokulandelela umzila:Amandla asebenzayo nobuqotho besignali kungafinyelelwa ngokubeka ingxenye ngokucophelela nokulandelela umzila. Hlanganisa izingxenye ezihlobene ndawonye futhi uqinisekise ukuxhumana okufushane, okuqondile phakathi kwazo. Nciphisa ubude bokulandelela futhi ugweme ukuwela imikhondo ebucayi. Sebenzisa izikhala ezifanele futhi ugcine amasignali abucayi kude nemithombo yomsindo.

Izindiza Eziphansi Nezamandla:Izindiza eziphansi nezinamandla zidlala indima ebalulekile ekwehliseni umsindo nasekukhuliseni ubuqotho besignali. Sebenzisa izindiza ezizinikezele ezisekelwe phansi namandla ukuze unikeze indiza eyinkomba ezinzile futhi unciphise ukuphazamiseka kwe-electromagnetic (EMI). Qinisekisa ukuxhumana okufanele kulezi zindiza ukugcina indlela ephansi ye-impedance yokubuyisela okwamanje.

Nquma ukujiya kwesendlalelo esifanele kanye nokungaguquki kwe-dielectric:Ukujiya kanye nokungaguquki kwe-dielectric kwesendlalelo ngasinye kusitaki kuthinta ukusakazwa kwesignali nokulawulwa kwe-impedance. Nquma inani le-impedance oyifunayo bese ukhetha ukujiya okufanele kanye nokungashintshi kwe-dielectric kungqimba ngalunye ngokufanele. Buyekeza imihlahlandlela yokuklama ye-PCB futhi ucabangele imvamisa yesignali nezidingo zomugqa wokudlulisela.

Umzila Wokuvinjelwa Okulawulwayo:Ukulawulwa kwe-impedance routing kubalulekile kumiklamo enesivinini esiphezulu ukuze kuncishiswe ukuboniswa kwesignali, ukugcina ubuqotho besignali, nokuvimbela amaphutha edatha. Nquma amanani eimpedance adingekayo wamasiginali abalulekile futhi usebenzise amasu omzila we-impedance alawulwayo njengepheya ehlukile, umzila we-stripline noma we-microstrip, kanye ne-impedance vias okulawulwayo.

Ukucatshangelwa Nokuphatha Okushisayo:Ukuphatha okushisayo kubalulekile kuzitaki ze-PCB ezehlukene. Ukukhipha ukushisa okufanele kuqinisekisa ukuthi izingxenye zisebenza ngaphakathi kwemikhawulo yazo yezinga lokushisa futhi kugwema umonakalo ongaba khona. Cabangela ukungeza izinto ezishisayo ukuze udlulisele ukushisa ezindizeni zangaphakathi zaphansi noma amaphedi ashisayo, sebenzisa i-thermal vias eduze nezingxenye zamandla aphezulu, futhi uhlanganise namasinki okushisa noma ukuthululwa kwethusi ukuze uthole ukusabalalisa ukushisa okungcono.

Ngokusebenzisa lawa maqhinga, ungaqinisekisa ukusatshalaliswa kwamandla okusebenzayo, unciphise umsindo, ulondoloze ubuqotho besignali, futhi uthuthukise ukuphatha okushisayo kusitaki se-PCB esendlalelo-4.

3. Ukucatshangelwa komklamo wokukhiqiza i-PCB enezingqimba ezi-4 :

- Balance manufacturability kanye nobunkimbinkimbi bomklamo.

- I-Design for Manufacturability (DFM) Imikhuba Engcono Kakhulu.

- Ngohlobo nokucatshangelwa kwesakhiwo.

- Imithetho yokuklama yesikhala, ububanzi bokulandelela, kanye nemvume.

- Sebenza nomkhiqizi we-PCB ukuze uzuze isitaki esilungile.

Ukulinganisa Ukwenziwa Kwezinto kanye Nobunkimbinkimbi Bedizayini:Lapho uklama i-PCB enezingqimba ezi-4, kubalulekile ukulinganisa phakathi kobunzima bomklamo kanye nokwenza kalula. Imiklamo eyinkimbinkimbi ingakhuphula izindleko zokukhiqiza kanye namaphutha angaba khona. Ukwenza amadizayini abe lula ngokulungiselela ukubekwa kwengxenye, ukuhlela umzila wesiginali, nokusebenzisa imithetho yedizayini esezingeni kungathuthukisa ukwenziwa.

I-Design for Manufacturability (DFM) Imikhuba Emihle:Faka ukucatshangelwa kwe-DFM kumiklamo ukuze uqinisekise ukukhiqiza okusebenza kahle futhi okungenaphutha. Lokhu kuhlanganisa ukulandela imithetho yokuklama evamile yemboni, ukukhetha izinto ezisetshenziswayo ezifanele kanye nogqinsi, kucatshangelwa izithiyo zokukhiqiza ezifana nobubanzi obuncane bokulandela umkhondo nesikhala, nokugwema izimo eziyinkimbinkimbi noma izici ezingase zengeze ebunkingeni bokukhiqiza.

Ngokucatshangelwa Kohlobo Nesakhiwo:Ukukhetha okulungile ngohlobo kanye nesakhiwo sayo kubalulekile ku-PCB enezingqimba ezi-4. Vias, vias blind, futhi vias wangcwatshwa ngamunye kunezinzuzo zabo kanye nokulinganiselwa. Cabangela ngokucophelela ukusetshenziswa kwazo ngokusekelwe enkingeni yokuklama nokuminyana, futhi uqinisekise ukuvunyelwa okufanele kanye nesikhala esizungezayo ukuze ugweme ukuphazamiseka kwesignali nokuhlangana kukagesi.

Imithetho Yedizayini Yesikhala, Ukulandelela Ububanzi, Nokusulwa:Landela imithetho enconyiwe yedizayini yesikhala, ukulandelela ububanzi, kanye nemvume enikezwe umkhiqizi we-PCB. Le mithetho iqinisekisa ukuthi umklamo ungakhiwa ngaphandle kwezinkinga, njengezikhindi zikagesi noma ukuwohloka kwesignali. Ukugcina isikhala esanele phakathi kokulandela umkhondo kanye nezingxenye, ukugcina imvume efanele ezindaweni ezinamandla kagesi, kanye nokusebenzisa ububanzi obufanele bokulandelela umthamo ofisa ukuthwala wamanje konke kuwukucatshangelwa okubalulekile.

Sebenza nomkhiqizi we-PCB ukuze uthole isitaki esifanele:Sebenza nomkhiqizi we-PCB ukuze unqume isitaki esilungile se-PCB enezingqimba ezi-4. Izinto okufanele zicatshangelwe zifaka izendlalelo zethusi, ukukhethwa nokubekwa kwe-dielectric material, isilawuli se-impedance esifiswayo, kanye nezidingo zesiginali yobuqotho. Ngokusebenzisana eduze nabakhiqizi, ungaqinisekisa ukuthi imiklamo ye-PCB ihambisana namandla abo nezinqubo zokukhiqiza, okuholela ekukhiqizeni okuphumelelayo nokungabizi kakhulu.

Sekukonke, ukuklama i-PCB enezingqimba ezi-4 kudinga ukuqonda okuphelele kokwenziwa, ukubambelela ezenzweni ezingcono kakhulu ze-DFM, ukucatshangelwa ngokucophelela kohlobo nesakhiwo, ukubambelela emithethweni yokuklama, nokusebenzisana nomkhiqizi we-PCB ukuze kuzuzwe ukunqwabelana okuphelele. Ngokucabangela lezi zici, ungathuthukisa ukwenziwa, ukwethembeka, kanye nokusebenza komklamo wakho we-PCB.

4. Izinzuzo nemikhawulo ye-PCB enezingqimba ezi-4:

- Ithuthukisa ubuqotho besignali, inciphisa umsindo futhi inciphise imiphumela ye-EMI.

- Amandla athuthukisiwe wokusebenzisa imiklamo enesivinini esikhulu.

- Inzuzo yokonga isikhala ye-compact electronics.

- Imikhawulo engaba khona nezinselele zokusebenzisa isitaki esinezendlalelo ezi-4.

Izinzuzo ze-4-layer PCB stackup:

Ubuqotho Besiginali Okuthuthukisiwe:

Izindiza ezengeziwe eziphansi nezinamandla kusitaki esinezendlalelo ezi-4 zisiza ukunciphisa umsindo wesignali futhi ziqinisekise ubuqotho obungcono besignali kumadizayini anesivinini esikhulu. Indiza ephansi isebenza njengendiza yereferensi ethembekile, inciphisa i-signal crosstalk futhi ithuthukise ukulawulwa kwe-impedance.

Umsindo owehlisiwe nomthelela we-EMI:

Ukuba khona kwezindiza eziphansi nezamandla kusitaki esinezendlalelo ezi-4 kusiza ukunciphisa ukuphazamiseka kwe-electromagnetic (EMI) ngokunikeza isivikelo kanye nokwenza ngcono isiginali. Lokhu kunikeza ukunciphisa umsindo okungcono futhi kuqinisekisa ukudluliswa kwesignali okucacile.

Amandla angeziwe wokusebenzisa imiklamo enesivinini esikhulu:

Ngezendlalelo ezengeziwe, abaklami banezinketho eziningi zomzila. Lokhu kunika amandla imiklamo eyinkimbinkimbi enesivinini esikhulu enezidingo ezilawulwayo ze-impedance, ukunciphisa ukuncishiswa kwesignali kanye nokuzuza ukusebenza okuthembekile kumafrikhwensi aphezulu.

Inzuzo yokonga isikhala:

Ukupakishwa kwezingqimba ezi-4 kuvumela ukwakheka okuminyene futhi okusebenzayo. Ihlinzeka ngezinketho ezengeziwe zomzila futhi inciphisa isidingo sokuxhumana okubanzi phakathi kwezingxenye, okuholela entweni encane yefomu yohlelo lonke lwe-elekthronikhi. Lokhu kunenzuzo ikakhulukazi kuma-electronics aphathwayo noma ama-PCB anabantu abaningi.

Imikhawulo nezinselele zokusebenzisa isitaki sezendlalelo ezi-4:

Izindleko:

Ukusebenzisa i-stackup yezendlalelo ezi-4 kukhulisa izindleko zizonke ze-PCB uma kuqhathaniswa ne-stackup yezendlalelo ezi-2. Izindleko zithonywa izici ezifana nenani lezendlalelo, ubunkimbinkimbi bomklamo, nenqubo yokukhiqiza edingekayo. Izendlalelo ezengeziwe zidinga izinto ezengeziwe, amasu okwenziwa anembe kakhudlwana, namandla omzila athuthukile.

Ubunkimbinkimbi bomklamo:

Ukuklama i-PCB enezingqimba ezi-4 kudinga ukuhlela ngokucophelela kune-PCB enezingqimba ezi-2. Izendlalelo ezengeziwe zinikeza izinselele ekubekweni kwengxenye, umzila nangokuhlela. Abaklami badinga ukucabangela ngokucophelela ubuqotho besignali, ukulawulwa kwe-impedance, nokusabalalisa amandla, okungase kube yinkimbinkimbi futhi kudle isikhathi.

Imikhawulo yokukhiqiza:

Ukukhiqiza ama-PCB anezingqimba ezi-4 kudinga izinqubo namasu okukhiqiza athuthuke kakhulu. Abakhiqizi badinga ukwazi ukuqondisa ngokunembile kanye nezingqimba ze-laminate, ukulawula ukushuba kwesendlalelo ngasinye, futhi baqinisekise ukuqondanisa okufanele kokubhobolwa kanye ne-vias. Akubona bonke abakhiqizi be-PCB abakwazi ukukhiqiza amabhodi anezingqimba ezi-4.

Umsindo nokuphazamiseka:

Nakuba isitaki sezendlalelo ezi-4 sisiza ukunciphisa umsindo ne-EMI, idizayini enganele noma amasu esakhiwo asengadala izinkinga zomsindo nokuphazamiseka. Ukupakishwa kwesendlalelo okungenziwanga ngendlela efanele noma ukubeka phansi okunganele kungaholela ekuhlanganeni okungahlosiwe kanye nokunciphisa isignali. Lokhu kudinga ukuhlela ngokucophelela nokucatshangelwa kwesakhiwo sokuklama nokubekwa kwendiza yaphansi.

Ukuphathwa kokushisa:

Ukuba khona kwezingqimba ezengeziwe kuthinta ukuchithwa kokushisa nokuphathwa kokushisa. Imiklamo eminyene enendawo elinganiselwe phakathi kwezingqimba ingaholela ekwenyukeni kokumelana nokushisa nokwanda kokushisa. Lokhu kudinga ukucatshangelwa ngokucophelela kwesakhiwo sengxenye, i-vias eshisayo, kanye nomklamo oshisayo uwonke ukugwema izinkinga zokushisa ngokweqile.

Kubalulekile ukuthi abaklami bahlole ngokucophelela izidingo zabo, becabangela izinzuzo nemikhawulo ye-PCB enezingqimba ezi-4, ukuze benze isinqumo esinolwazi mayelana nesitaki esingcono kakhulu somklamo wabo othile.

Ngokufigqiwe,ukuzuza isitaki se-PCB esendlalelo esingu-4 esilungile kubalulekile ekuqinisekiseni idizayini ye-elekthronikhi ethembekile nesebenza kakhulu. Ngokuqonda okuyisisekelo, ukucabangela amasu okuklama, nokusebenzisana nabakhiqizi be-PCB, abaklami bangakwazi ukusizakala ngokusatshalaliswa kwamandla okusebenzayo, ubuqotho besignali, kanye nemiphumela encishisiwe ye-EMI. Kumele kukhunjulwe ukuthi umklamo oyimpumelelo wesitaki esinezendlalelo ezi-4 udinga indlela ecophelelayo kanye nokucatshangelwa kokubekwa kwengxenye, umzila, ukuphathwa okushisayo kanye nokwenziwa. Ngakho-ke thatha ulwazi olunikezwe kulo mhlahlandlela bese uqala uhambo lwakho lokuzuza isitaki se-PCB esendlalelo esi-4 esihle kakhulu sephrojekthi yakho elandelayo!

Isikhathi sokuthumela: Aug-18-2023

Emuva