Ama-PCB anezendlalelo eziyi-16 ahlinzeka ngobunkimbinkimbi nokuguquguquka okudingekayo ngezinto zesimanje zikagesi. Idizayini enekhono nokukhethwa kokulandelana kokunqwabelanisa nezindlela zokuxhumanisa i-interlayer kubalulekile ukuze kuzuzwe ukusebenza kahle kwebhodi. Kulesi sihloko, sizohlola okucatshangwayo, imihlahlandlela, nemikhuba engcono kakhulu yokusiza abaklami nonjiniyela bakhe amabhodi esekethe asebenza kahle nathembekile ezendlalelo eziyi-16.

1.Ukuqonda Okuyisisekelo Kokulandelana Kwama-PCB kwezingqimba eziyi-16

1.1 Incazelo nenjongo ye-stacking order

Ukulandelana kokunqwabelanisa kubhekisela ekuhlelweni nasekuhlelekeni lapho izinto ezifana nezendlalelo zethusi nezivikelayo zihlanganiswa ndawonye ukuze zenze ibhodi lesifunda elinezingqimba eziningi.Ukulandelana kokunqwabelanisa kunquma ukubekwa kwezingqimba zesignali, izendlalelo zamandla, izendlalelo zomhlabathi, nezinye izingxenye ezibalulekile isitaki.

Inhloso eyinhloko yokulandelana kwe-stacking ukufeza izakhiwo ezidingekayo zikagesi kanye nemishini yebhodi. Idlala indima ebalulekile ekunqumeni ukuthintana kwebhodi lesifunda, ubuqotho besignali, ukusatshalaliswa kwamandla, ukuphathwa kokushisayo, kanye nokwenzeka kokukhiqiza. Ukulandelana kokunqwabelanisa kuphinde kuthinte ukusebenza kukonke, ukwethembeka, nokwenziwa kwebhodi.

1.2 Izinto ezithinta idizayini yokulandelana kokunqwabelanisa: Kunezici ezimbalwa okufanele zicatshangelwe lapho uklama ukulandelana kwesitaki

I-PCB enezingqimba eziyi-16:

a) Ukucatshangelwa kukagesi:Isakhiwo sesignali, amandla, kanye nezindiza eziphansi kufanele zithuthukiswe ukuze kuqinisekiswe ubuqotho besignali obufanele, ukulawulwa kokuphazamiseka, kanye nokwehliswa kokuphazanyiswa kwe-electromagnetic.

b) Ukucatshangelwa kokushisa:Ukubekwa kwamandla nezindiza eziphansi kanye nokufakwa kwe-thermal vias kusiza ukuqeda ukushisa ngokuphumelelayo nokugcina izinga lokushisa elilungile lokusebenza kwengxenye.

c) Izingqinamba zokukhiqiza:Ukulandelana kokunqwabelanisa okukhethiwe kufanele kucabangele amandla kanye nemikhawulo yenqubo yokukhiqiza ye-PCB, njengokutholakala kwezinto ezibonakalayo, inani lezendlalelo, i-drill aspect ratio,kanye nokunemba kokuqondanisa.

d) Ukuthuthukisa Izindleko:Ukukhethwa kwezinto zokwakha, inani lezendlalelo, nobunkimbinkimbi bokunqwabelanisa kufanele kuhambisane nesabelomali sephrojekthi kuyilapho kuqinisekisa ukusebenza okudingekile nokwethembeka.

1.3 Izinhlobo ezijwayelekile zokulandelana kwebhodi lesifunda elinezingqimba eziyi-16:Kunochungechunge olujwayelekile lokunqwabelanisa lwezendlalelo eziyi-16.

PCB, kuye ngokusebenza oyifunayo kanye nezidingo. Ezinye izibonelo ezivamile zihlanganisa:

a) Ukulandelana kwesitaki se-Symmetric:Lokhu kulandelana kuhilela ukubeka izendlalelo zesignali ngokulinganayo phakathi kwamandla nezingqimba zomhlabathi ukuze kuzuzwe ubuqotho besignali enhle, i-crosstalk encane, kanye nokunqamuka kokushisa okulinganiselwe.

b) Ukulandelana kokunqwabelanisa okulandelanayo:Kulokhu kulandelana, izingqimba zesignali zilandelana phakathi kwamandla kanye nezingqimba zomhlabathi. Inikeza ukulawula okukhulu phezu kokuhlelwa kwesendlalelo futhi kunenzuzo ukuhlangabezana nezimfuneko ezithile zesignali yobuqotho.

c) Ukuhleleka okuhlanganisiwe okuhlanganisiwe:Lokhu kubandakanya inhlanganisela yama-oda wokustakika alinganayo nama-oda alandelanayo. Ivumela ukwenziwa ngokwezifiso kanye nokwenza kahle kokwakheka kwezingxenye ezithile zebhodi.

d) Ukulandelana kwezitaki ezizwela isiginali:Lokhu kulandelana kubeka izendlalelo zesignali ezibucayi eduze nendiza yaphansi ukuze kuvikeleke kangcono umsindo nokuhlukaniswa.

2. Ukucatshangelwa Okubalulekile Kokukhetha Ukulandelana Kwesitaki se-PCB kwezingqimba eziyi-16:

2.1 Ubuqotho besignali nokucatshangelwa kobuqotho bamandla:

Ukulandelana kwe-stacking kunomthelela omkhulu ekuthembekeni kwesignali nobuqotho bamandla ebhodi. Ukubekwa kahle kwesignali kanye nezindiza zamandla/eziphansi kubalulekile ekwehliseni ubungozi bokuhlanekezelwa kwesignali, umsindo, nokuphazamiseka kazibuthe. Okucatshangelwayo okubalulekile kuhlanganisa:

a) Ukubekwa kwesendlalelo sesignali:Izendlalelo zesignali yesivinini esikhulu kufanele zibekwe eduze nendiza yaphansi ukuze kuhlinzekwe indlela yokubuya ene-inductance ephansi futhi kuncishiswe ukuhlangana komsindo. Izendlalelo zesignali kufanele futhi zendlalwe ngokucophelela ukuze kuncishiswe ukutsheka kwesignali nokumadanisa ubude.

b) Ukusatshalaliswa kwendiza yamandla:Ukulandelana kokunqwabelanisa kufanele kuqinisekise ukusatshalaliswa kwendiza yamandla okwanele ukusekela ubuqotho bamandla. Amandla anele nezindiza eziphansi kufanele zibekwe ngendlela ehlelekile ukuze kuncishiswe ukwehla kwamandla kagesi, ukungaqhubeki kwe-impedance, kanye nokuhlanganisa umsindo.

c) I-Decoupling Capacitors:Ukubekwa kahle kwama-decoupling capacitor kubalulekile ukuze kuqinisekiswe ukudluliswa kwamandla okwanele kanye nokunciphisa umsindo wokuphakelwa kwamandla. Ukulandelana kokunqwabelanisa kufanele kunikeze ukusondela kanye nokuba seduze kwama-capacitor e-decoupling kumandla nezindiza eziphansi.

2.2 Ukuphathwa kokushisa kanye nokuchithwa kokushisa:

Ukuphatha okushisayo okusebenzayo kubalulekile ekuqinisekiseni ukwethembeka nokusebenza kwebhodi lesifunda. Ukulandelana kokunqwabelanisa kufanele kucabangele ukubekwa okufanele kwamandla nezindiza eziphansi, i-thermal vias, nezinye izindlela zokupholisa. Okucatshangelwayo okubalulekile kuhlanganisa:

a) Ukusatshalaliswa kwendiza yamandla:Ukusabalalisa okwanele kwamandla nezindiza eziphansi kuso sonke isitaki kusiza ukuqondisa ukushisa kude nezingxenye ezibucayi futhi kuqinisekise ukusatshalaliswa kwezinga lokushisa okufanayo ebhodini lonke.

b) Indlela yokushisa:Ukulandelana kokunqwabelanisa kufanele kuvumele ukushisa okusebenzayo ngokubeka ukuze kube lula ukulahlwa kokushisa kusuka kungqimba engaphakathi kuye kweyangaphandle noma usinki wokushisa. Lokhu kusiza ukuvimbela izindawo ezishisayo zendawo futhi kuqinisekisa ukulahlwa kokushisa okusebenzayo.

c) Ukubekwa kwengxenye:Ukulandelana kokunqwabelanisa kufanele kucabangele ukuhlelwa kanye nokuba seduze kwezingxenye zokushisisa ukuze kugwenywe ukushisa ngokweqile. Ukuqondanisa kahle kwezingxenye ezinezici zokupholisa ezifana namasinki okushisa noma amafeni kufanele futhi kucatshangelwe.

2.3 Izingqinamba zokukhiqiza kanye nokwenza ngcono izindleko:

Ukulandelana kokunqwabelanisa kufanele kucabangele izingqinamba zokukhiqiza kanye nokuthuthukisa izindleko, njengoba zidlala indima ebalulekile ekwenzekeni nasekuthengeni kwebhodi. Okucatshangelwayo kuhlanganisa:

a) Ukutholakala kwezinto:Ukulandelana kokunqwabelanisa okukhethiwe kufanele kuhambisane nokutholakala kwezinto kanye nokuhambisana kwazo nenqubo yokukhiqiza ye-PCB ekhethiwe.

b) Inani lezendlalelo nobunkimbinkimbi:Ukulandelana kokunqwabelanisa kufanele kuklanywe ngaphakathi kwemikhawulo yenqubo yokukhiqiza ye-PCB ekhethiwe, kucatshangelwa izici ezifana nenani lezendlalelo, i-aspect ratio ye-drill, nokunemba kokuqondanisa.

c) Ukwenza ngcono izindleko:Ukulandelana kwama-stacking kufanele kuthuthukise ukusetshenziswa kwezinto futhi kunciphise inkimbinkimbi yokukhiqiza ngaphandle kokuphazamisa ukusebenza okudingekile nokwethembeka. Kufanele ihlose ukunciphisa izindleko ezihlobene nokulahlwa kwezinto ezibonakalayo, ukucubungula inkimbinkimbi kanye nokuhlanganisa.

2.4 Ukuqondanisa ungqimba kanye ne-signal crosstalk:

Ukulandelana kwezitaki kufanele kubhekane nezinkinga zokuqondanisa isendlalelo futhi kunciphise ukungqubuzana kwesignali okungaba nomthelela omubi kubuqotho besignali. Okucatshangelwayo okubalulekile kuhlanganisa:

a) Ukupakishwa kwe-Symmetrical:Ukupakishwa okulinganayo kwezingqimba zesignali phakathi kwamandla kanye nezendlalelo zomhlabathi kusiza ukunciphisa ukuhlangana nokunciphisa i-crosstalk.

b) Imizila emibili ehlukene:Ukulandelana kwezitaki kufanele kuvumele izendlalelo zesignali ukuthi ziqondaniswe kahle ukuze kuhanjiswe umzila osebenzayo wamasignali ahlukene wesivinini esikhulu. Lokhu kusiza ukugcina ubuqotho besignali futhi kunciphise i-crosstalk.

c) Ukuhlukaniswa kwamasignali:Ukulandelana kokunqwabelanisa kufanele kucabangele ukuhlukaniswa kwamasiginali e-analog nedijithali ukuze kuncishiswe i-crosstalk nokuphazamiseka.

2.5 Ukulawulwa kokuphazamiseka kanye nokuhlanganiswa kwe-RF/microwave:

Kuzinhlelo zokusebenza ze-RF/microwave, ukulandelana kokunqwabelanisa kubalulekile ukuze kuzuzwe ukulawulwa okufanele kwe-impedance nokuhlanganiswa. Okucatshangelwayo okubalulekile kuhlanganisa:

a) I-impedance elawulwayo:Ukulandelana kokunqwabelanisa kufanele kuvumele idizayini ye-impedance elawulwayo, kucatshangelwa izici ezifana nobubanzi bokulandelela, ukujiya kwe-dielectric, nokuhlelwa kongqimba. Lokhu kuqinisekisa ukusakazwa kwesignali okulungile nokumataniswa kokuphazamiseka kwamasiginali e-RF/microwave.

b) Ukubekwa kwesendlalelo sesignali:Amasiginali e-RF/microwave kufanele abekwe ngendlela ehlelekile eduze kongqimba lwangaphandle ukuze kuncishiswe ukuphazamiseka kwamanye amasignali futhi anikeze isignali esakazwa kangcono.

c) I-RF Shielding:Ukulandelana kokupakisha kufanele kufake ukubekwa okufanele kwezingqimba zomhlabathi nezivikelayo ukuze kuhlukaniswe nokuvikela amasignali e-RF/microwave ekuphazamiseni.

3.Izindlela Zokuxhumanisa I-Interlayer

3.1 Ngemigodi, imigodi engaboni kanye nemigodi egqitshiwe:

I-Vias isetshenziswa kabanzi ekwakhiweni kwebhodi lesifunda eliphrintiwe (PCB) njengendlela yokuxhuma izingqimba ezihlukene. Ziyizimbobo ezibhoboziwe kuzo zonke izingqimba ze-PCB futhi zihlanganiswe ukuze zinikeze ukuqhubeka kukagesi. Ngezimbobo zihlinzeka ngoxhumano lukagesi oluqinile futhi kulula ukwenza nokulungisa. Kodwa-ke, adinga osayizi abakhulu bebhithi yokubhoboza, ethatha indawo ebalulekile ku-PCB futhi ikhawulele izinketho zomzila.

I-Vis eyimpumputhe nengcwatshwe ezinye izindlela zokuxhumanisa i-interlayer ezinikeza izinzuzo ekusebenziseni isikhala kanye nokuguquguquka kwemizila.

I-Vis eyimpumputhe ibhojwa ukusuka phezulu kwe-PCB futhi inqamule izendlalelo zangaphakathi ngaphandle kokudlula kuzo zonke izendlalelo. Zivumela ukuxhumana phakathi kwezingqimba eziseduze kuyilapho zishiya izendlalelo ezijulile zingathinteki. Lokhu kuvumela ukusetshenziswa ngokuphumelelayo kwesikhala sebhodi futhi kunciphisa inani lemigodi yokubhoboza. I-vias engcwatshiwe, ngakolunye uhlangothi, izimbobo ezivaleleke ngokuphelele ngaphakathi kwezendlalelo zangaphakathi ze-PCB futhi azinwebeki kuzingqimba zangaphandle. Banikeza ukuxhumana phakathi kwezingqimba zangaphakathi ngaphandle kokuthinta izendlalelo zangaphandle. Ama-Vis angcwatshwayo anezinzuzo ezinkulu zokonga isikhala kunezimbobo nezimbobo ezingaboni ngoba azithathi noma yisiphi isikhala kungqimba olungaphandle.

Ukukhetha ngokusebenzisa izimbobo, i-vias eyimpumputhe, kanye ne-vias egqitshiwe kuncike ezidingweni ezithile zomklamo we-PCB. Ngezimbobo ngokuvamile zisetshenziswa emiklamo elula noma lapho ukuqina nokulungiseka kuyizinto eziyinhloko ezikhathazayo. Emiklamo emikhulu lapho isikhala siyisici esibalulekile, njengamadivayisi aphathwayo, ama-smartphone, namakhompyutha aphathekayo, ama-vias angaboni kanye nangcwatshiwe ayakhethwa.

3.2 I-Micropore kanyeUbuchwepheshe be-HDI:

I-Microvias izimbobo ezinobubanzi obuncane (imvamisa engaphansi kwama-microns angu-150) ezihlinzeka ngoxhumano lwe-interlayer olunokuminyana okuphezulu kuma-PCB. Banikeza izinzuzo ezibalulekile ku-miniaturization, ubuqotho besignali kanye nokuguquguquka komzila.

I-Microvias ingahlukaniswa ngezinhlobo ezimbili: i-microvias ye-hole kanye ne-blind microvias. Ama-Microvias akhiwa ngokumba izimbobo ukusuka phezulu kwe-PCB futhi anwebe kuzo zonke izingqimba. Ama-microvias ayimpumputhe, njengoba negama liphakamisa, adlulela kuphela ezingqimbeni ezithile zangaphakathi futhi angangeni kuzo zonke izendlalelo.

I-High-density interconnect (HDI) ubuchwepheshe obusebenzisa ama-microvias nezindlela zokukhiqiza ezithuthukisiwe ukuze kuzuzwe ukuminyana kwesekethe nokusebenza okuphezulu. Ubuchwepheshe be-HDI buvumela ukubekwa kwezingxenye ezincane kanye nomzila oqinile, okuholela ezicini zefomu ezincane kanye nobuqotho besignali ephakeme. Ubuchwepheshe be-HDI bunikeza izinzuzo ezimbalwa kunobuchwepheshe be-PCB bendabuko ngokwemibandela yokwenza kancane, ukusabalalisa isignali okuthuthukisiwe, ukuhlanekezela kwesignali okuncishisiwe, nokusebenza okuthuthukisiwe. Ivumela imiklamo ye-multilayer enama-microvias amaningi, ngaleyo ndlela ifinyeze ubude bokuxhumanisa futhi inciphise amandla e-parasitic kanye ne-inductance.

Ubuchwepheshe be-HDI buphinde buvumele ukusetshenziswa kwezinto ezithuthukisiwe njengama-laminates ama-high-frequency kanye nezingqimba ezincane ze-dielectric, ezibaluleke kakhulu ekusetshenzisweni kwe-RF/microwave. Inikeza ukulawula okungcono kwe-impedance, kunciphisa ukulahlekelwa kwesignali futhi iqinisekisa ukudluliswa kwesignali okuthembekile okuthembekile.

3.3 Izinto zokuxhumanisa i-Interlayer nezinqubo:

Ukukhethwa kwezinto nezindlela zokuxhuma kwe-interlayer kubalulekile ekuqinisekiseni ukusebenza kahle kukagesi, ukwethembeka kwemishini kanye nokukhiqizwa kwama-PCB. Ezinye izinto ezisetshenziswa kakhulu zokuxhumanisa i-interlayer namasu yilezi:

a) Ithusi:I-Copper isetshenziswa kabanzi kuma-conductive layers kanye ne-vias yama-PCB ngenxa yokuguquguquka kwayo okuhle kakhulu kanye nokuthengiswa kwayo. Ivamise ukugxunyekwa embobeni ukuze inikeze ukuxhumana okuthembekile kukagesi.

b) Soldering:Amasu okuthengisa, afana ne-wave soldering noma i-reflow soldering, avame ukusetshenziselwa ukwenza ukuxhumana kukagesi phakathi kwezimbobo kuma-PCB nezinye izinto. Faka i-solder unama ku-via bese usebenzisa ukushisa ukuze uncibilikise i-solder futhi wakhe uxhumano oluthembekile.

c) I-Electroplating:Amasu e-Electroplating afana ne-electroless copper plating noma i-electrolytic copper asetshenziselwa ukupuleta nge-vias ukuthuthukisa ukuhamba nokuqinisekisa ukuxhumana okuhle kukagesi.

d) Ukuhlanganisa:Amasu okubopha, afana ne-adhesive bonding noma i-thermocompression bonding, asetshenziselwa ukuhlanganisa izakhiwo ezinengqimba ndawonye nokudala ukuxhumana okuthembekile.

e) Impahla ye-Dielectric:Ukukhethwa kwempahla ye-dielectric yesitaki se-PCB kubalulekile ekuxhumekeni kwe-interlayer. Ama-laminates ama-high frequency afana ne-FR-4 noma i-Rogers laminates ngokuvamile asetshenziselwa ukuqinisekisa ubuqotho besignali enhle nokunciphisa ukulahlekelwa kwesignali.

3.4 Idizayini nencazelo ehlukahlukene:

Idizayini yezingxenye ezihlukene zesitaki se-PCB inquma izici zikagesi nezomshini zokuxhuma phakathi kwezendlalelo. Okucatshangelwayo okubalulekile kokuklama kwezigaba ezihlukene zifaka:

a) Ukuhlelwa kwesendlalelo:Ukuhlelwa kwesiginali, amandla, kanye nezindiza eziphansi ngaphakathi kwesitaki se-PCB kuthinta ubuqotho besignali, ubuqotho bamandla, nokuphazanyiswa kwe-electromagnetic (EMI). Ukubekwa kahle nokuqondanisa kwezendlalelo zesignali ngamandla nezindiza eziphansi kusiza ukunciphisa ukuhlangana komsindo nokuqinisekisa izindlela eziphansi zokubuya kwe-inductance.

b) Ukulawulwa kokuphazamiseka:Idizayini yezigaba ezihlukene kufanele icabangele izidingo ezilawulwayo zokuthikamezeka, ikakhulukazi kumasiginali edijithali noma e-RF/microwave anesivinini esikhulu. Lokhu kuhilela ukukhetha okufanele kwezinto ezisetshenziswa yi-dielectric kanye nobukhulu ukuze kuzuzwe isici esifiselekayo se-impedance.

c) Ukuphathwa kokushisa:Idizayini ye-cross-section kufanele icabangele ukuchithwa kokushisa okusebenzayo kanye nokuphathwa kokushisa. Ukubekwa ngendlela efanele kwamandla nezindiza eziphansi, i-thermal vias, kanye nezingxenye ezinezindlela zokupholisa (njengamasinki okushisa) kusiza ukuqeda ukushisa nokugcina izinga lokushisa elilungile lokusebenza.

d) Ukuthembeka kwemishini:Idizayini yesigaba kufanele icabangele ukwethembeka kokusebenza, ikakhulukazi ezinhlelweni ezingase zibe ngaphansi kokuhamba ngebhayisikili okushisayo noma ingcindezi yokusebenza. Ukukhetha okufanele kwezinto zokwakha, amasu okubopha, nokucushwa kwesitaki kusiza ukuqinisekisa ubuqotho besakhiwo nokuqina kwe-PCB.

4.Iziqondiso Zokuklama ze-PCB enezingqimba eziyi-16

4.1 Ukwabiwa kwesendlalelo nokusabalalisa:

Lapho uklama ibhodi lesifunda elinezingqimba eziyi-16, kubalulekile ukwaba ngokucophelela futhi usabalalise izendlalelo ukuze kuthuthukiswe ukusebenza kahle nobuqotho besignali. Nansi eminye imihlahlandlela yokwabiwa kwesigaba

kanye nokusabalalisa:

Nquma inani lezendlalelo zesignali ezidingekayo:

Cabanga ngobunkimbinkimbi bomklamo wesifunda kanye nenani lamasignali adinga ukuhanjiswa. Nikeza izendlalelo zamasignali ezanele ukuze zikwazi ukuthwala zonke izimpawu ezidingekayo, uqinisekise indawo eyanele yomzila futhi ugweme ukweqisa.ukuminyana. Nikeza izindiza eziphansi nezinamandla:

Nikeza okungenani izendlalelo ezimbili zangaphakathi ezindizeni eziphansi nezinamandla. Indiza yaphansi isiza ukuhlinzeka ngereferensi ezinzile yamasiginali futhi inciphise ukuphazanyiswa kwe-electromagnetic (EMI). Indiza yamandla ihlinzeka ngenethiwekhi yokusabalalisa amandla evimbe kakhulu esiza ukunciphisa ukwehla kwamandla kagesi.

Hlukanisa izendlalelo zesignali ezibucayi:

Ngokuya ngohlelo lokusebenza, kungase kudingeke ukuthi kuhlukaniswe izendlalelo zesignali ezizwelayo noma zesivinini esiphezulu kusukela kungqimba olunomsindo noma lwamandla aphezulu ukuze kuvinjelwe ukuphazamiseka kanye ne-crosstalk. Lokhu kungenziwa ngokubeka umhlabathi ozinikele noma izindiza zamandla phakathi kwazo noma ngokusebenzisa izingqimba zokuzihlukanisa.

Sabalalisa ngokulinganayo izendlalelo zesignali:

Sabalalisa izendlalelo zesignali ngokulinganayo kuso sonke isitaki sebhodi ukuze unciphise ukuhlangana phakathi kwamasignali aseduze futhi ugcine ubuqotho besignali. Gwema ukubeka izendlalelo zesignali eduze kwenye endaweni efanayo yesitaki ukuze unciphise i-interlayer crosstalk.

Cabangela amasignali amaza aphezulu:

Uma idizayini yakho iqukethe amasignali emvamisa ephezulu, cabanga ukubeka izendlalelo zesignali yemvamisa ephezulu eduze kwezendlalelo zangaphandle ukuze unciphise imiphumela yolayini wokudlulisela futhi unciphise ukubambezeleka kokusabalalisa.

4.2 Umzila kanye nomzila wesignali:

Idizayini yokulandela umkhondo nokulandela isignali kubalulekile ukuze kuqinisekiswe ubuqotho obufanele besignali kanye nokunciphisa ukuphazamiseka. Nansi eminye imihlahlandlela yesakhiwo kanye nemizila yesignali kumabhodi esekethe anezendlalelo eziyi-16:

Sebenzisa ukulandelelwa okubanzi kwamasignali amanje:

Kumasiginali aphethe amandla aphezulu, njengamandla nokuxhumeka komhlaba, sebenzisa ukulandela ngomkhondo okubanzi ukuze unciphise ukumelana nokwehla kwamandla kagesi.

I-impedance efanayo yamasiginali wesivinini esikhulu:

Ngamasignali anesivinini esikhulu, qinisekisa ukuthi i-trace impedance ifana nesici somugqa wokudlulisela ukuvimbela ukubonakaliswa kanye nokuncishiswa kwesignali. Sebenzisa amasu edizayini ye-impedance elawulwayo kanye nezibalo ezilungile zobubanzi bokulandelela.

Nciphisa ubude bokulandelela kanye namaphoyinti e-crossover:

Gcina ubude bokulandelela bufushane ngangokunokwenzeka futhi unciphise inani lamaphoyinti e-crossover ukuze unciphise amandla e-parasitic, inductance, kanye nokuphazamiseka. Lungiselela ukubekwa kwengxenye futhi usebenzise izendlalelo zomzila ezizinikele ukuze ugweme ukulandelelwa okude, okuyinkimbinkimbi.

Hlukanisa amasignali anesivinini esikhulu kanye nesivinini esiphansi:

Hlukanisa amasignali anesivinini esikhulu kanye nesivinini esiphansi ukuze unciphise umthelela womsindo kumasignali esivinini esikhulu. Beka amasignali anesivinini esikhulu ezendlaleloni zesignali ezizinikele futhi uzigcine zikude namandla aphezulu noma izingxenye ezinomsindo.

Sebenzisa amapheya ahlukile kumasiginali anesivinini esikhulu:

Ukuze unciphise umsindo futhi ugcine ubuqotho besignali kumasiginali ahlukayo wesivinini esikhulu, sebenzisa amasu okuhamba ngakubili okuhlukile. Gcina i-impedance nobude bamapheya ahlukanisiwe kufaniswe ukuze uvimbele isiginali i-skew kanye ne-crosstalk.

4.3 Isendlalelo esingaphansi kanye nokusabalalisa isendlalelo samandla:

Ukusatshalaliswa okufanele kwezindiza eziphansi nezinamandla kubalulekile ekuzuzeni ubuqotho bamandla kanye nokunciphisa ukuphazamiseka kukazibuthe. Nansi eminye imihlahlandlela yezabelo zendiza ephansi nezamandla kumabhodi esekethe anezendlalelo eziyi-16:

Nikeza izindiza ezizinikezele zomhlabathi namandla kagesi:

Yabela okungenani izendlalelo ezimbili zangaphakathi zezindiza ezizinikezele zomhlabathi namandla. Lokhu kusiza ukunciphisa amaluphu aphansi, ukunciphisa i-EMI, futhi kunikeze indlela yokubuya enezithiyo eziphansi kumasiginali wefrikhwensi ephezulu.

Hlukanisa izindiza zedijithali neze-analog:

Uma umklamo unezigaba zedijithali ne-analog, kunconywa ukuthi kube nezindiza ezihlukene zomhlabathi zesigaba ngasinye. Lokhu kusiza ukunciphisa ukuhlangana komsindo phakathi kwezigaba zedijithali ne-analogi futhi kuthuthukise ubuqotho besignali.

Beka izindiza eziphansi nezamandla eduze nezindiza ezibonisa izimpawu:

Beka izindiza eziphansi nezinamandla eduze nezindiza zesignali eziziphakelayo ukuze kuncishiswe indawo eyiluphu futhi kuncishiswe ukulandwa komsindo.

Sebenzisa ama-via amaningi ngezindiza zamandla:

Sebenzisa ama-vias amaningi ukuxhuma izindiza zamandla ukuze usabalalise ngokulinganayo amandla futhi unciphise ukuvinjelwa kwendiza yamandla. Lokhu kusiza ukunciphisa ukwehla kwamandla kagesi futhi kuthuthukise ubuqotho bamandla.

Gwema izintamo eziwumngcingo ezindizeni zamandla:

Gwema izintamo eziminyene ezindizeni zamandla njengoba zingabangela ukuminyana kwamanje futhi kwandise ukumelana, kubangele ukwehla kwamandla kagesi kanye nokungasebenzi kahle kwendiza yamandla. Sebenzisa ukuxhumana okuqinile phakathi kwezindawo ezahlukene zendiza yamandla.

4.4 Iphedi ye-thermal nangokubeka:

Ukubekwa kahle kwamaphedi ashisayo kanye ne-vias kubalulekile ekukhipheni ukushisa ngempumelelo nokuvimbela izingxenye ekushiseni ngokweqile. Nansi eminye imihlahlandlela yephedi eshisayo nangokubeka kumabhodi esekethe anezendlalelo eziyi-16:

Beka iphedi eshisayo ngaphansi kwezingxenye ezikhiqiza ukushisa:

Khomba ingxenye ekhiqiza ukushisa (njengesikhulisi samandla noma i-IC yamandla aphezulu) bese ubeka iphedi eshisayo ngaphansi kwayo ngokuqondile. Lawa ma-thermal pads ahlinzeka ngendlela yokushisa eqondile yokudlulisa ukushisa kungqimba lwangaphakathi lwe-thermal.

Sebenzisa ama-thermal vias amaningi ukuqeda ukushisa:

Sebenzisa izindlela eziningi ezishisayo ukuze uxhume isendlalelo esishisayo nesendlalelo sangaphandle ukuze unikeze ukulahlwa kokushisa okuphumelelayo. Lawa ma-vias angabekwa ngephethini emile ezungeze iphedi eshisayo ukuze kuzuzwe ukushisa okulinganayo.

Cabangela i-thermal impedance kanye nesitaki sesendlalelo:

Uma udizayina ama-avas ashisayo, cabangela ukuthikamezeka kokushisayo kwento yebhodi kanye nesitaki sesendlalelo.Lungisa ngosayizi nesikhala ukuze unciphise ukumelana nokushisa futhi ukwandise ukunqanyulwa kokushisa.

4.5 Ukubekwa Kwengxenye Nobuqotho Besiginali:

Ukubekwa kwengxenye efanele kubalulekile ekugcineni ubuqotho besignali nokunciphisa ukuphazamiseka. Nansi eminye imihlahlandlela yokubeka izingxenye ebhodini lesifunda elinezingqimba eziyi-16:

Izingxenye ezihlobene neqembu:

Izingxenye ezihlobene neqembu eziyingxenye yesistimu engaphansi efanayo noma ezinokusebenzisana okuqinile kukagesi. Lokhu kunciphisa ubude bokulandelela futhi kunciphisa ukuncishiswa kwesignali.

Gcina izingxenye zesivinini esikhulu ziseduze:

Beka izingxenye ezinesivinini esikhulu, njengama-oscillator ama-high-frequency oscillator noma ama-microcontroller, eduze komunye nomunye ukuze unciphise ubude bokulandelela futhi uqinisekise ubuqotho besignali obufanele.

Nciphisa ubude bokulandelela bezimpawu ezibalulekile:

Nciphisa ubude bokulandelela amasignali abalulekile ukuze unciphise ukubambezeleka kokusabalalisa kanye nokuncishiswa kwesignali. Beka lezi zingxenye eduze ngangokunokwenzeka.

Izingxenye ezibucayi ezihlukene:

Izingxenye ezingezwani nomsindo, njengezingxenye ze-analog noma izinzwa zezinga eliphansi, kusukela kumandla aphezulu noma izingxenye ezinomsindo ukuze kuncishiswe ukuphazamiseka nokugcina ubuqotho besignali.

Cabanga nge-decoupling capacitor:

Beka ama-decoupling capacitor eduze ngangokunokwenzeka kumaphini wamandla wengxenye ngayinye ukuze unikeze amandla ahlanzekile futhi unciphise ukushintshashintsha kwamandla kagesi. Lawa ma-capacitor asiza ukuzinzisa ukunikezwa kwamandla futhi anciphise ukuhlangana komsindo.

5.Amathuluzi Okulingisa Nokuhlaziya Omklamo Wesitaki

5.1 Isofthiwe yokumodela ne-3D yokulingisa:

Isofthiwe ye-3D yokumodela neyokulingisa iyithuluzi elibalulekile lokuklama isitaki ngoba ivumela abaklami ukuthi bakhe izethulo ezibonakalayo zezitaki ze-PCB. Isofthiwe ingakwazi ukubona ngeso lengqondo izendlalelo, izingxenye, nokusebenzisana kwazo ngokomzimba. Ngokulingisa isitaki, abaklami bangakwazi ukuhlonza izinkinga ezingaba khona ezifana ne-signal crosstalk, i-EMI, kanye nezingqinamba zemishini. Kuphinde kusize ukuqinisekisa ukuhlelwa kwezingxenye nokuthuthukisa idizayini ye-PCB iyonke.

5.2 Amathuluzi okuhlaziya ubuqotho besignali:

Amathuluzi okuhlaziya ubuqotho besignali abalulekile ekuhlaziyeni nasekuthuthukiseni ukusebenza kukagesi kwezitaki ze-PCB. Lawa mathuluzi asebenzisa ama-algorithms ezibalo ukuze alingise futhi ahlaziye ukuziphatha kwesignali, okuhlanganisa nokulawula i-impedance, ukuboniswa kwesignali, nokuhlanganisa umsindo. Ngokwenza ukulingisa nokuhlaziya, abaklami bangakwazi ukuhlonza izinkinga ezingaba khona zobuqotho besignali ekuqaleni kwenqubo yokuklama futhi benze izinguquko ezidingekayo ukuze kuqinisekiswe ukudluliswa kwesignali okuthembekile.

5.3 Amathuluzi okuhlaziya okushisayo:

Amathuluzi okuhlaziya okushisayo adlala indima ebalulekile ekwakhiweni kwezitaki ngokuhlaziya nokuthuthukisa ukuphathwa okushisayo kwama-PCB. Lawa mathuluzi alingisa ukuchithwa kokushisa nokusabalalisa kwezinga lokushisa ngaphakathi kwesendlalelo ngasinye sesitaki. Ngokumodela ngokunembile izindlela zokuchithwa kwamandla nezindlela zokudlulisa ukushisa, abaklami bangakwazi ukuhlonza izindawo ezishisayo, bathuthukise ukubekwa kwezingqimba zethusi kanye ne-thermal vias, futhi baqinisekise ukupholisa okufanele kwezingxenye ezibalulekile.

5.4 Idizayini yokwenziwa:

Idizayini yokwenziwa iyingxenye ebalulekile yedizayini yesitaki. Kunezinhlobonhlobo zamathuluzi esofthiwe atholakalayo angasiza ukuqinisekisa ukuthi isitaki esikhethiwe singenziwa kahle. Lawa mathuluzi ahlinzeka ngempendulo mayelana nokuba nokwenzeka kokufinyelela isitaki osifunayo, kucatshangelwa izici ezifana nokutholakala kwempahla, ukujiya kongqimba, inqubo yokukhiqiza, nezindleko zokukhiqiza. Basiza abaklami ukwenza izinqumo ezinolwazi ukuze balungiselele ukunqwabelanisa ukuze kwenziwe lula ukukhiqiza, ukunciphisa ubungozi bokubambezeleka, nokwandisa isivuno.

6.Isinyathelo Ngesinyathelo Inqubo Yokuklama Yama-PCB Ezendlalelo Eziyi-16

6.1 Iqoqo lezidingo zokuqala:

Kulesi sinyathelo, qoqa zonke izidingo ezidingekayo ze-16-layer PCB design. Qonda ukusebenza kwe-PCB, ukusebenza kukagesi okudingekayo, izingqinamba zemishini, nanoma yimiphi imihlahlandlela ethile yokuklama noma izindinganiso okufanele zilandelwe.

6.2 Ukwabiwa kwengxenye nokuhlelwa:

Ngokwezidingo, nikeza izingxenye ku-PCB futhi unqume ukuhlelwa kwazo. Cabangela izici ezifana nobuqotho besignali, ukucatshangelwa kokushisa, kanye nezingqinamba zemishini. Izingxenye zeqembu ezisekelwe kuzici zikagesi futhi uzibeke ngendlela ehlelekile ebhodini ukuze unciphise ukuphazamiseka nokuthuthukisa ukugeleza kwesignali.

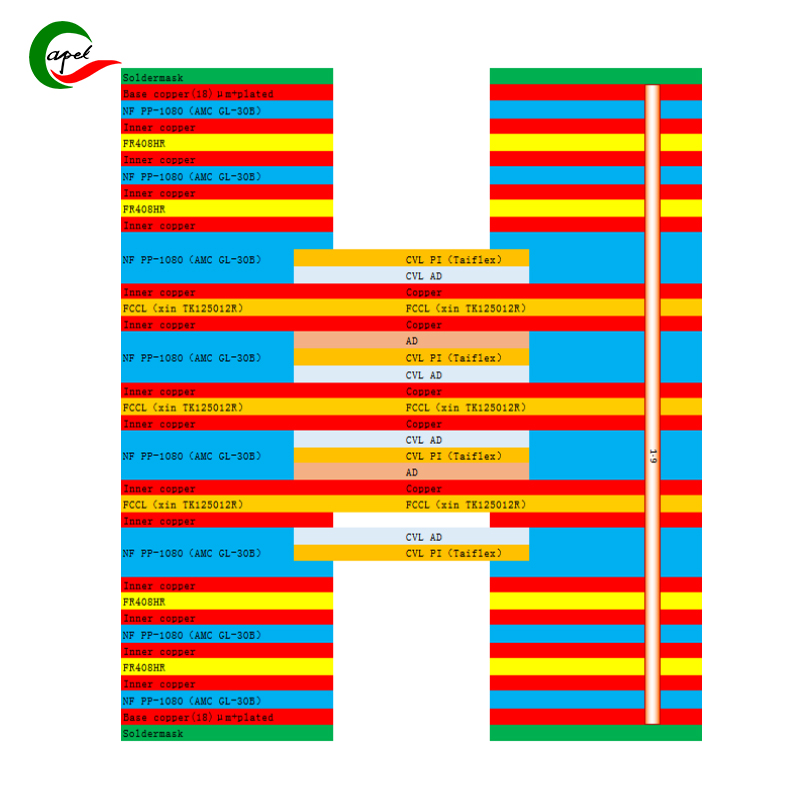

6.3 Idizayini yesitaki nokusabalalisa isendlalelo:

Nquma idizayini yesitaki ye-PCB enezingqimba eziyi-16. Cabangela izici ezifana ne-dielectric constant, thermal conductivity, kanye nezindleko zokukhetha into efanele. Yabela isignali, amandla, kanye nezindiza eziphansi ngokwezidingo zikagesi. Beka izindiza eziphansi nezamandla ngokulinganayo ukuze uqinisekise isitaki esinokulinganisela futhi uthuthukise ubuqotho besignali.

6.4 Umzila wesiginali kanye nokwenza kahle komzila:

Kulesi sinyathelo, ukulandelelwa kwesignali kuhanjiswa phakathi kwezingxenye ukuze kuqinisekiswe ukulawulwa okufanele kwe-impedance, ubuqotho besignali, kanye nokunciphisa isignali ye-crosstalk. Lungiselela umzila ukuze unciphise ubude bamasiginali abalulekile, gwema ukuwela imikhondo ebucayi, futhi ugcine ukuhlukana phakathi kwamasignali anesivinini esikhulu kanye nesivinini esiphansi. Sebenzisa amapheya ahlukile kanye namasu okulawula okuvimbayo lapho kudingeka.

6.5 Ukuxhumana kwe-Interlayer nangokubeka:

Hlela ukubekwa kokuxhuma ama-vias phakathi kwezingqimba. Nquma okulungile ngohlobo, olufana nembobo noma imbobo eyimpumputhe, ngokusekelwe kuguquko lwesendlalelo noxhumo lwengxenye. Lungiselela ngesakhiwo ukuze unciphise ukubonakaliswa kwesignali, ukungaqhubeki kwe-impedance, futhi ulondoloze ukusatshalaliswa okulinganayo ku-PCB.

6.6 Ukuqinisekiswa kokugcina komklamo kanye nokulingiswa:

Ngaphambi kokukhiqiza, ukuqinisekiswa kokugcina komklamo kanye nokulingiswa kuyenziwa. Sebenzisa amathuluzi okulingisa ukuze uhlaziye imiklamo ye-PCB yobuqotho besignali, ubuqotho bamandla, ukuziphatha okushisayo, kanye nokwenziwa. Qinisekisa idizayini ngokumelene nezidingo zokuqala futhi wenze izinguquko ezidingekayo ukuze uthuthukise ukusebenza futhi uqinisekise ukwenziwa.

Hlanganyela futhi uxhumane nabanye ababambiqhaza abanjengonjiniyela bakagesi, onjiniyela bemishini, namaqembu akhiqizayo kuyo yonke inqubo yokuklama ukuze uqinisekise ukuthi zonke izidingo ziyahlangatshezwa futhi nezinkinga ezingaba khona ziyaxazululwa. Buyekeza njalo futhi uphindaphinde imiklamo ukuze uhlanganise impendulo nokuthuthukiswa.

I-7.Imikhuba Engcono Kakhulu Yemboni kanye Nezimo

7.1 Amacala aphumelele edizayini ye-PCB enezingqimba eziyi-16:

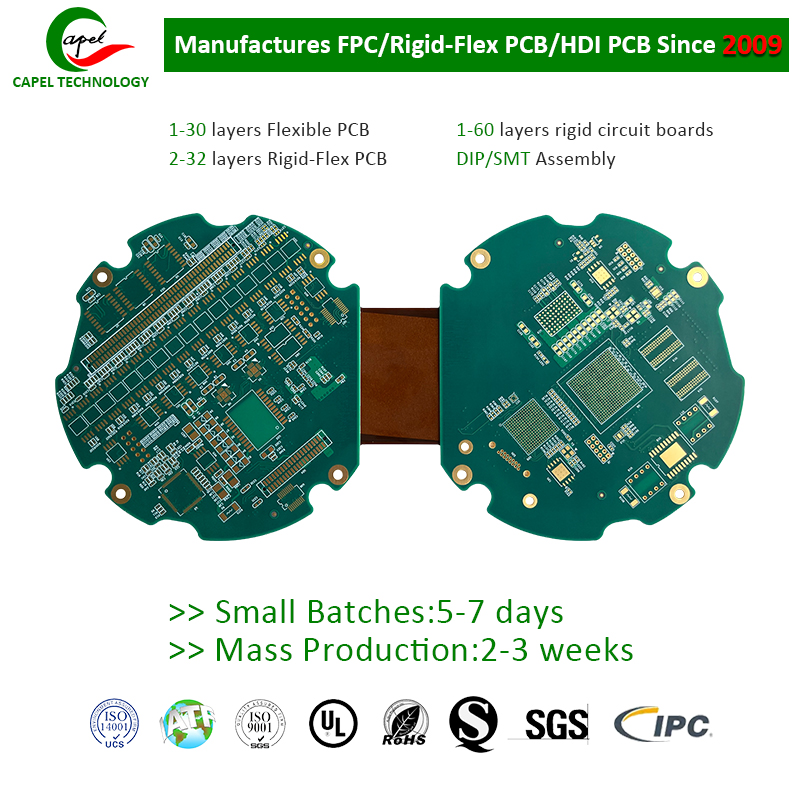

Isifundo 1:I-Shenzhen Capel Technology Co., Ltd. iklame ngempumelelo i-PCB enezingqimba eziyi-16 yemishini yenethiwekhi enesivinini esikhulu. Ngokucubungula ngokucophelela ubuqotho besignali kanye nokusatshalaliswa kwamandla, bafinyelela ukusebenza okuphezulu futhi banciphise ukuphazamiseka kwe-electromagnetic. Isihluthulelo sempumelelo yabo idizayini yesitaki elungiselelwe ngokugcwele esebenzisa ubuchwepheshe bomzila obungangeni obulawulwayo.

Isifundo 2:I-Shenzhen Capel Technology Co., Ltd. iklame i-PCB enezingqimba eziyi-16 yesisetshenziswa sezokwelapha esiyinkimbinkimbi. Ngokusebenzisa inhlanganisela yendawo yokukhweza kanye nezingxenye zembobo, bathole umklamo ohlangene kodwa onamandla. Ukubekwa kwengxenye ngokucophelela kanye nomzila ophumelelayo kuqinisekisa ubuqotho besignali nokwethembeka okuhle kakhulu.

7.2 Funda ekuhlulekeni futhi ugweme izingibe:

Isifundo 1:Abanye abakhiqizi be-pcb bahlangabezane nezinkinga zesignali yobuqotho ekwakhiweni kwe-PCB enezingqimba eziyi-16 zemishini yezokuxhumana. Izizathu zokwehluleka kwakuwukucatshangelwa okwanele kokulawulwa kwe-impedance kanye nokuntuleka kokusatshalaliswa okufanele kwendiza yaphansi. Isifundo esitholiwe ukuhlaziya ngokucophelela izidingo zobuqotho besignali nokuphoqelela imihlahlandlela eqinile yokuklama i-impedance.

Isifundo 2:Abanye abenzi be-pcb babhekane nezinselele zokukhiqiza nge-PCB yayo enezingqimba eziyi-16 ngenxa yobunkimbinkimbi bomklamo. Ukusetshenziswa ngokweqile kwama-vias angaboni kanye nezingxenye eziminyene kuholela ebunzimeni bokukhiqiza nokuhlanganisa. Isifundo esitholiwe ukuthola ibhalansi phakathi kwedizayini eyinkimbinkimbi nokwenziwayo uma kunikezwe amandla omkhiqizi we-PCB okhethiwe.

Ukuze ugweme izingibe nezingozi ekwakhiweni kwe-PCB enezingqimba eziyi-16, kubalulekile ukuthi:

a.Ziqonde kahle izidingo nezingqinamba zomklamo.

b.Ukucushwa okustakiwe okuthuthukisa ubuqotho besignali nokusabalalisa amandla. c.Sabalalisa ngokucophelela futhi uhlele izingxenye zokuthuthukisa ukusebenza nokwenza lula ukukhiqiza.

d.Qinisekisa izindlela ezifanele zomzila, njengokulawula ukuthinta kanye nokugwema ukusetshenziswa ngokweqile kwama- blind vias.

e. Ukusebenzisana nokuxhumana ngempumelelo nabo bonke ababambiqhaza ababambe iqhaza enqubweni yokuklama, okuhlanganisa onjiniyela bakagesi nabemishini kanye namaqembu akhiqizayo.

f.Yenza ukuqinisekiswa kwedizayini okuphelele kanye nokulingisa ukuhlonza nokulungisa izinkinga ezingaba khona ngaphambi kokukhiqiza.

Isikhathi sokuthumela: Sep-26-2023

Emuva