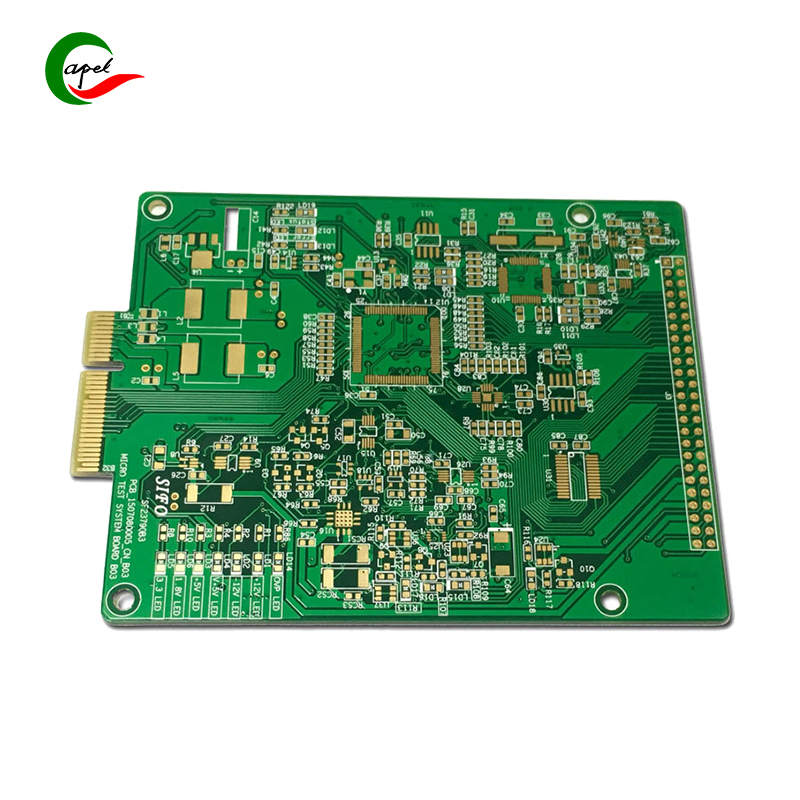

I-Multilayer PCBs Prototyping Manufacturers Amabhodi e-PCB e-Quick Turn

Ikhono lenqubo ye-PCB

| Cha. | Iphrojekthi | Izinkomba zobuchwepheshe |

| 1 | Isendlalelo | 1-60(ungqimba) |

| 2 | Indawo yokucubungula ephezulu | 545 x 622 mm |

| 3 | Ubuncane bobukhulu | 4(ungqimba)0.40mm |

| 6(ungqimba) 0.60mm | ||

| 8(ungqimba) 0.8mm | ||

| 10(ungqimba)1.0mm | ||

| 4 | Ububanzi bomugqa obuncane | 0.0762mm |

| 5 | Isikhala esincane | 0.0762mm |

| 6 | Imbobo encane yomshini | 0.15mm |

| 7 | Imbobo yodonga lwethusi ukujiya | 0.015mm |

| 8 | Ukubekezelelwa kwe-metalized aperture | ±0.05mm |

| 9 | Ukubekezelela ukungena kwe-metallized | ±0.025mm |

| 10 | Ukubekezelelana kwezimbobo | ±0.05mm |

| 11 | Ukubekezelela Dimensional | ±0.076mm |

| 12 | Ibhuloho elincane le-solder | 0.08mm |

| 13 | Ukumelana ne-insulation | 1E+12Ω (evamile) |

| 14 | Isilinganiso sobukhulu bepuleti | 1:10 |

| 15 | Ukushaqeka okushisayo | 288 ℃ (izikhathi ezi-4 ngemizuzwana eyi-10) |

| 16 | Ihlanekezelwe futhi igobile | ≤0.7% |

| 17 | Amandla okulwa nogesi | >1.3KV/mm |

| 18 | Amandla okulwa nokuhlubula | 1.4N/mm |

| 19 | I-Solder imelana nobunzima | ≥6H |

| 20 | Ukuncipha komlilo | 94V-0 |

| 21 | Ukulawulwa kwe-impedance | ±5% |

Senza i-Multilayer PCBs prototyping ngesipiliyoni seminyaka engu-15 ngobungcweti bethu

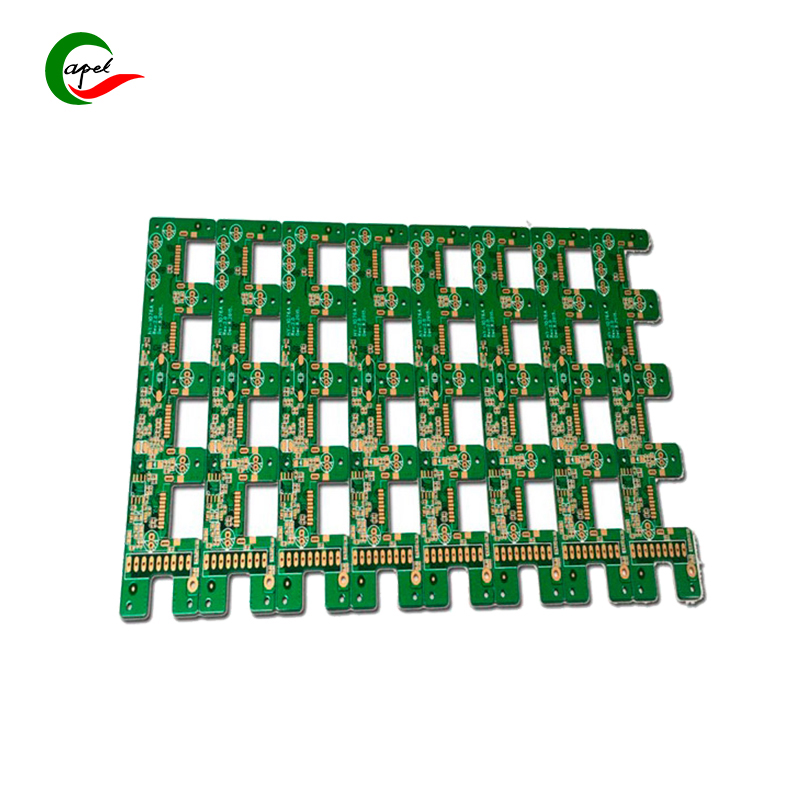

4 ungqimba Amabhodi Flex-Rigid

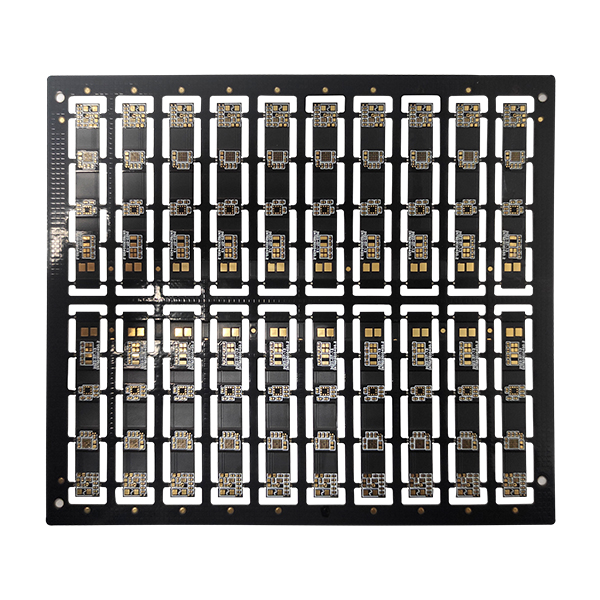

8 ungqimba we-Rigid-Flex PCBs

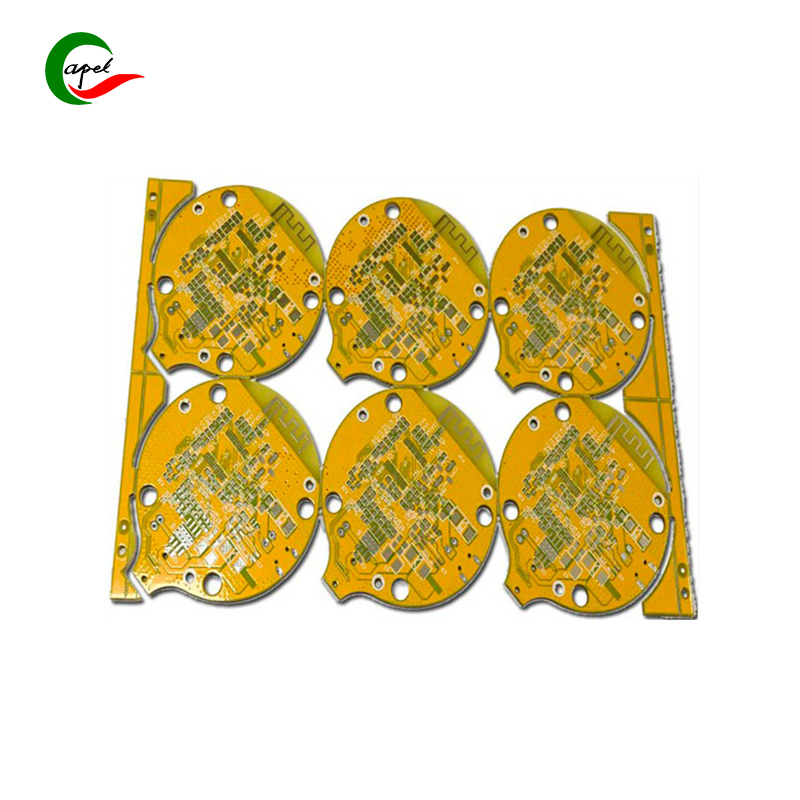

8 ungqimba HDI PCBs

Izisetshenziswa zokuhlola nokuhlola

Ukuhlola Isibonakhulu

Ukuhlolwa kwe-AOI

Ukuhlolwa kwe-2D

Ukuhlolwa kwe-Impedans

Ukuhlolwa kwe-RoHS

I-Flying Probe

Umhloli Ovundlile

Ukugoba i-Teste

Isevisi yethu ye-prototyping yama-PCB amaningi

. Ukuhlinzeka ngosekelo lobuchwepheshe Ukuthengisa kwangaphambili kanye nangemuva kokuthengisa;

. Yenza ngokwezifiso izendlalelo ezingafika kwezingama-40, i-1-2days ijika ngokushesha i-prototyping, ukuthengwa kwengxenye, i-SMT Assembly;

. Ibhekelela kokubili Idivayisi Yezokwelapha, Ukulawulwa Kwezimboni, Izimoto, Izindiza, I-Consumer Electronics, i-IOT, i-UAV, Ezokuxhumana njll.

. Amaqembu ethu onjiniyela nabacwaningi bazinikele ekugcwaliseni izidingo zakho ngokunemba nangobuchwepheshe.

I-Multilayer PCB inikeza ukwesekwa okuthuthukile kwezobuchwepheshe emkhakheni wezimoto

1. Isistimu yokuzijabulisa yemoto: I-PCB enezingqimba eziningi ingasekela imisebenzi eyengeziwe yomsindo, ividiyo kanye nokuxhumana okungenantambo, ngaleyo ndlela inikeze umuzwa wokuzijabulisa wemoto ocebile. Ingakwazi ukwamukela izendlalelo eziningi zesekethe, ihlangabezane nezidingo ezahlukahlukene zokucubungula umsindo nevidiyo, futhi isekele ukudluliswa kwesivinini esikhulu nemisebenzi yokuxhuma okungenantambo, njenge-Bluetooth, i-Wi-Fi, i-GPS, njll.

2. Uhlelo lokuphepha: I-PCB enezingqimba eziningi ingahlinzeka ngokusebenza kokuphepha okuphezulu nokuthembeka, futhi isetshenziswa ezimotweni ezisebenzayo nezingenzi lutho. Ingakwazi ukuhlanganisa izinzwa ezihlukahlukene, amayunithi okulawula kanye namamojula okuxhumana ukuze ibone imisebenzi efana nesexwayiso sokushayisana, ukubhuleka okuzenzakalelayo, ukushayela okuhlakaniphile, nokulwa nobugebengu. Idizayini ye-PCB enezingqimba eziningi iqinisekisa ukuxhumana okusheshayo, okunembile nokuthembekile kanye nokuxhumana phakathi kwamamojula esistimu yokuphepha ahlukahlukene.

3. Uhlelo lokusiza ukushayela: I-PCB enezingqimba eziningi ingahlinzeka ngokucubungula isignali enembayo kanye nokudluliswa kwedatha okusheshayo kwezinhlelo zokusiza ukushayela, njengokupaka okuzenzakalelayo, ukutholwa kwendawo eyimpumputhe, ukulawulwa kohambo oluguquguqukayo kanye nezinhlelo zokusiza ukugcina umzila, njll.

Lezi zinhlelo zidinga ukucutshungulwa kwesignali okunembile kanye nokudluliswa kwedatha okusheshayo. Futhi amandla okubona ngesikhathi kanye nokwahlulela, kanye nokusekelwa kwezobuchwepheshe kwe-PCB enezingqimba eziningi kungahlangabezana nalezi zidingo.

4. Uhlelo lokuphatha injini: Isistimu yokuphatha injini ingasebenzisa i-PCB enezingqimba eziningi ukuze ibone ukulawula okunembayo nokuqapha injini.

Ingakwazi ukuhlanganisa izinzwa ezihlukahlukene, ama-actuator namayunithi okulawula ukuze kuqashwe futhi kulungiswe imingcele efana nokunikezwa kukaphethiloli, isikhathi sokucisha kanye nokulawula ukungcola kwenjini ukuze kuthuthukiswe ukusebenza kahle kukaphethiloli nokunciphisa intuthu ephumayo.

5. Uhlelo lokushayela ngogesi: I-PCB enezingqimba eziningi inikeza ukwesekwa kwezobuchwepheshe okuthuthukisiwe kokuphathwa kwamandla kagesi kanye nokudluliswa kwamandla kwezimoto zikagesi nezimoto eziyingxubevange. Ingakwazi ukusekela ukudluliswa kwamandla aphezulu kanye nokulawulwa kwe-oscillation, ithuthukise ukusebenza kahle nokuthembeka kwesistimu yokulawula ibhethri, futhi iqinisekise umsebenzi ohlanganisiwe wamamojula ahlukahlukene ohlelweni lokushayela ugesi.

Amabhodi wesekethe ye-Multilayer ensimini yezimoto FAQ

1. Ubukhulu nesisindo: Isikhala emotweni silinganiselwe, ngakho ubukhulu nesisindo sebhodi lesifunda se-multilayer nakho kuyizici okudingeka zicatshangelwe. Amabhodi amakhulu kakhulu noma asindayo angakhawulela ukwakheka nokusebenza kwemoto, ngakho-ke kunesidingo sokunciphisa usayizi webhodi nesisindo ekwakhiweni ngenkathi kugcinwa izidingo zokusebenza nokusebenza.

2. I-Anti-vibration kanye nomthelela wokumelana: Imoto izoba ngaphansi kokudlidliza kanye nemithelela ehlukahlukene ngesikhathi sokushayela, ngakho ibhodi lesekethe le-multilayer lidinga ukuthi libe ne-anti-vibration enhle kanye nokumelana nomthelela. Lokhu kudinga ukuhlelwa okunengqondo kwesakhiwo esisekela ibhodi lesifunda kanye nokukhethwa kwezinto ezifanele ukuze kuqinisekiswe ukuthi ibhodi lesifunda lisengakwazi ukusebenza ngokuzinzile ngaphansi kwezimo zomgwaqo ezinzima.

3. Ukuvumelana nezimo zemvelo: Indawo yokusebenza yezimoto iyinkimbinkimbi futhi iyashintsha, futhi amabhodi esekethe anezingqimba eziningi adinga ukwazi ukuzivumelanisa nezimo ezihlukahlukene zemvelo, njengezinga lokushisa eliphezulu, izinga lokushisa eliphansi, umswakama, njll. Ngakho-ke, kuyadingeka khetha izinto ezinokumelana okuhle kokushisa okuphezulu, ukumelana nokushisa okuphansi nokumelana nomswakama, futhi Thatha izinyathelo zokuzivikela ezihambisanayo ukuze uqinisekise ukuthi ibhodi lesifunda lingasebenza ngokuthembekile ezindaweni ezihlukahlukene.

4. Ukuhambisana nokuklama kwesixhumi esibonakalayo: Amabhodi esekethe e-multilayer adinga ukuhambisana futhi axhunywe namanye amadivaysi kagesi kanye nezinhlelo, ngakho umklamo ohambisanayo wesixhumi esibonakalayo nokuhlolwa kwesixhumi esibonakalayo kuyadingeka. Lokhu kuhlanganisa ukukhethwa kwezixhumi, ukuhambisana nezindinganiso zokusebenzelana, kanye nokuqinisekiswa kokuzinza kwesignali yesixhumi esibonakalayo nokwethembeka.

6. Ukupakishwa kwe-chip nokuhlela: ukupakishwa kwe-chip nokuhlela kungase kuhileleke kumabhodi wesekethe we-multilayer. Lapho uklama, kuyadingeka ukucabangela ifomu lephakheji nosayizi we-chip, kanye nesixhumi esibonakalayo kanye nendlela yokushisa nokuhlela. Lokhu kuqinisekisa ukuthi i-chip izohlelwa futhi isebenze ngendlela efanele nangokwethembeka.