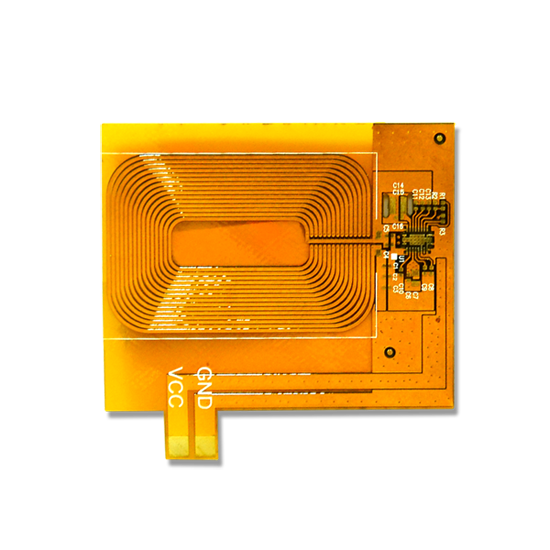

umakhalekhukhwini rigid flex PCB | smartphone flex PCB circuit board

Yiziphi izinkinga ezinzima kakhulu okumele amakhasimende e-antenna fpc flexible circuit board azixazulule?

-UCapel uneminyaka engu-15 yesipiliyoni sobuchwepheshe

Ukudluliswa kwesignali yemvamisa ephezulu: Qinisekisa ukuthi ibhodi lesekhethi lingakwazi ukudlulisa ngempumelelo amasignali amaza aphezulu ukuze kugwenywe ukuncipha kanye nokuphazamiseka kwesignali.

Amandla okumelana nokuphazamiseka: Qinisekisa ukuthi ibhodi lesekhethi alithintwa ezinye izisetshenziswa zikagesi noma ukuphazamiseka kazibuthe ngesikhathi kusetshenziswa umakhalekhukhwini.

Usayizi nesisindo: Usayizi nesisindo sebhodi lesekhethi kudingeka kucatshangelwe ukuze kuqinisekiswe ukuthi ihambisana nezidingo zokuklanywa kwefoni.

Ukuvumelana nezimo nokuqina: Qinisekisa ukuthi ibhodi lesifunda elivumelana nezimo alilikali kalula lapho ligotshwa noma limpintsha, futhi linokusebenza okuzinzile kwesikhathi eside.

Ukusebenza Kwezindleko: Amakhasimende angase abhekane nezinselele ezidinga ibhalansi phakathi kwezindleko nokusebenza.

Ukukhiqiza: Kubandakanya ukukhiqizwa kwenqwaba ephumelelayo nezinqubo zokuhlanganisa, kanye nobuchwepheshe bokuqinisekisa ikhwalithi yebhodi lesifunda nokungaguquguquki.

Ukukhetha impahla: Kudingeka kucatshangelwe izinto ezisebenza kahle kakhulu ezifanele amabhodi esekethe aguquguqukayo kanye nokuqinisekisa ukwethembeka kwe-supply chain. Ukuvikelwa kwemvelo kanye nokusimama: Ukuqinisekisa ukuthi inqubo yokukhiqiza yamabhodi esekethe ihlangabezana nezidingo zemvelo kanye nokuthi ukulahlwa kwamabhodi esekethe yemfucuza kungafinyelela ukusimama.

Ukuhlola nokuqinisekisa: Kubandakanya ukuhlolwa okusebenzayo nokuqinisekiswa kwamabhodi esekethe aguquguqukayo ukuze kuqinisekiswe ukuthotshelwa kwemininingwane kanye nezidingo zokusebenza.

Ukusekelwa Kobuchwepheshe: Amakhasimende angase adinge ukuhlinzeka ngosekelo lobuchwepheshe nezisombululo zokubhekana nezinselele nezinkinga ezinhlelweni zokusebenza ezingokoqobo.

Ukudluliswa kwesignali yemvamisa ephezulu: Lapho beklama izimpondo ze-PCB eziguquguqukayo, onjiniyela bazosebenzisa izimiso zedizayini zakudala zemigqa yokudlulisela yamaza aphezulu, njengemigqa ye-microstrip. Ngokuhambisana nesici esifanelekile sokumatanisa nokuklanywa kwezintambo, qinisekisa ukuthi amasiginali wefrikhwensi ephezulu angadluliselwa ebhodini lesifunda ngokuncishiswa okuncane. Onjiniyela bazosebenzisa isofthiwe yokulingisa ukwenza isizinda semvamisa kanye nokuhlaziywa kwesizinda sesikhathi ukuze baqinisekise ukusebenza kokudluliswa kwesignali. Isibonelo, lapho onjiniyela baklama amabhodi esekethe aguquguqukayo, balungiselela ububanzi bomugqa, ukuphakama kwe-dielectric, kanye nezakhiwo ezibonakalayo ngokuhlaziywa kokulingisa ukuze kuqinisekiswe ukuthi ukusebenza kokudlulisela kumafrikhwensi athile kuhlangabezana nezidingo.

Ikhono lokunqanda ukuphazamiseka: Lapho kuxazulula inkinga yekhono lokunqanda ukuphazamiseka, onjiniyela bazosebenzisa ubuchwepheshe obufana nomklamo wokuvikela kanye nokucutshungulwa kwezintambo eziphansi. Ngokungeza izendlalelo ezifanele zokuvikela kanye nezintambo eziphansi ku-PCB yeselula eguquguqukayo, ukuphazamiseka kwamanye amasiginali kazibuthe kusiginali yothi lweselula kungancishiswa ngempumelelo. Onjiniyela bangase futhi basebenzise ukulingisa kanye nesilinganiso sangempela ukuze baqinisekise ukusebenza okulwa nokuphazamiseka kwebhodi lesifunda ukuze kuqinisekiswe ukuzinza nokwethembeka kwalo. Isibonelo, kumaphrojekthi wangempela, onjiniyela bangase benze izivivinyo zokuhambisana nozibuthe we-electromagnetic kumabhodi esekethe aguquguqukayo omakhalekhukhwini ukuze baqinisekise amandla abo okumelana nokuphazamiseka ezindaweni zangempela.

Usayizi nesisindo: Lapho baklama i-PCB eguquguqukayo yothi lweselula, onjiniyela kudingeka bacabangele izidingo zedizayini yeselula futhi bacabangele imikhawulo yosayizi nesisindo. Ngokusebenzisa ubuchwepheshe obufana nama-substrates aguquguqukayo kanye nezintambo ezinhle, ubukhulu nesisindo samabhodi wesifunda kungancishiswa ngempumelelo. Isibonelo, onjiniyela bangakhetha i-substrate eguquguqukayo enogqinsi oluncane futhi babeke amasekhethi ngendlela evumelana nezimo ngokuya ngezidingo ezithile zokuklama zezimpondo zocingo ukuze kwehliswe usayizi nesisindo sebhodi lesekethe.

Ukuvumelana nezimo nokuqina: Ukuthuthukisa ukuguquguquka nokuqina kwamabhodi esekethe aguquguqukayo, onjiniyela bazosebenzisa ama-substrates aguquguqukayo athuthukile nezinqubo zokuxhuma. Isibonelo, khetha izinto eziguquguqukayo ezinezakhiwo ezinhle zokugoba futhi usebenzise imiklamo efanele yesixhumi ukuze uqinisekise ukuthi ibhodi lesifunda alilimali kalula ngaphansi kokugoba noma ukukhishwa njalo. Onjiniyela bangase bahlole ukuguquguquka nokuqina kwebhodi ngokuhlolwa kokuhlola nokuqinisekisa ukwethembeka.

Ukusebenza kahle kwezindleko: Onjiniyela balungiselela ukwakheka nokukhethwa kwezinto ezibonakalayo ukuze balinganisele izindleko nokusebenza. Isibonelo, khetha ama-substrates asebenza kahle kakhulu nezindleko ezimaphakathi, wehlise ukusetshenziswa kwempahla ngedizayini yezintambo ezithuthukisiwe, futhi usebenzise izinqubo zokukhiqiza ezisebenza kahle nezisetshenziswa ezizenzakalelayo ukuze uthuthukise ukusebenza kahle kokukhiqiza, ngaleyo ndlela wehlise izindleko ngenkathi uqinisekisa ukusebenza. Kumaphrojekthi wangempela, onjiniyela bangasebenzisa amathuluzi okuhlaziya izindleko, njengesofthiwe ye-DFM (Design for Manufacturing), ukuze bahlole ukusebenza kahle kwezindleko zezixazululo zedizayini futhi banikeze amakhasimende isixazululo esingcono kakhulu.

Ukukhiqiza: Onjiniyela badinga ukuklama ukukhiqizwa kwenqwaba nezinqubo zokuhlanganisa ukuze kuqinisekiswe ikhwalithi nokuvumelana kwamabhodi esekethe. Isibonelo, phakathi nenqubo yokukhiqiza, onjiniyela bangasebenzisa i-SMT (Surface Mount Technology) kanye nemishini yomhlangano ezenzakalelayo ukuze kuqinisekiswe ukukhiqizwa kwebhodi lesifunda eliphezulu. Onjiniyela bangase futhi badizayine izinqubo ezihambisanayo zokuhlola nokuhlola ukuze baqaphe ngempumelelo ikhwalithi yamabhodi esekethe futhi baqinisekise ukuthi bayahlangabezana nezidingo.

Ukukhetha izinto ezibonakalayo: Onjiniyela badinga ukukhetha izinto ezisebenza kahle kakhulu ezifanele amabhodi wesekethe we-antenna yeselula futhi baqinisekise ukwethembeka kochungechunge lokunikezela. Isibonelo, lapho kukhethwa izinto zokwakha, onjiniyela bangase bacabangele izici ezifana ne-dielectric constant, ukulahleka kwe-dielectric, kanye nezakhiwo zokugoba zama-substrates aguquguqukayo, futhi baxoxisane nabahlinzeki ukuze baqinisekise ukutholakala nokuzinza kwezinto. Onjiniyela bangase benze ukuhlolwa kwezinto ezibonakalayo nokuqhathanisa ukuze bakhethe isixazululo esifanelekile sezinto ezibonakalayo.

Ukuvikelwa kwemvelo nokusimama: Onjiniyela bazosebenzisa izinqubo zokukhiqiza ezivumelana nemvelo nokukhetha okusimeme ukuze kuqinisekiswe ukuthi inqubo yokukhiqiza ye-FPC antenna flex PCB ihlangabezana nezidingo zemvelo. Isibonelo, cabanga ukusebenza kwemvelo kwezinto ngesikhathi sesigaba sokuklama, khetha izinto ezithobela iziqondiso ze-RoHS, futhi udizayine izinqubo zokukhiqiza ezigaywa kabusha. Onjiniyela bangase futhi basebenze nabahlinzeki ukuze basungule amasistimu e-supply chain ahlangabezana nezinhloso zokusimama.

Ukuhlola nokuqinisekisa: Onjiniyela bazoqhuba izivivinyo nokuqinisekiswa okuhlukahlukene ku-antenna yeselula ye-Fpc ukuze baqinisekise ukuthi bayahlangabezana nezicaciso kanye nezidingo zokusebenza. Isibonelo, imishini yokuhlola imvamisa ephezulu isetshenziselwa ukuhlola ukusebenza kokudluliswa kwesignali, futhi okokusebenza kokuhlola ukuhambelana kuka-electromagnetic kusetshenziselwa ukuhlola ukusebenza kokulwa nokuphazamiseka ukuze kuqinisekiswe ukusebenza kwebhodi lesekethe. Onjiniyela bangase futhi basebenzise okokusebenza kokuhlola ukwethembeka ukuze baqinisekise ukuqina nokuqina kwamabhodi esekethe.

Ukwesekwa kobuchwepheshe: Onjiniyela bazohlinzeka ngosekelo lwezobuchwepheshe oluchwepheshile nezisombululo lapho amakhasimende ebhekene nezinselele zohlelo lokusebenza. Isibonelo, uma ikhasimende lihlangabezana nenkinga yokusebenza ekusetshenzisweni kwebhodi lesifunda le-antenna yeselula, unjiniyela angase enze ukuhlaziya okujulile kwembangela yenkinga, aphakamise uhlelo lokuthuthukisa, futhi anikeze ukusekela nosizo ngendlela engokoqobo. izicelo. Onjiniyela bangase banikeze amakhasimende izixazululo eziqondiwe ngezindlela ezihlukahlukene, njengokusekelwa kwevidiyo okukude, isiqondiso sobuchwepheshe esisendaweni, njll.

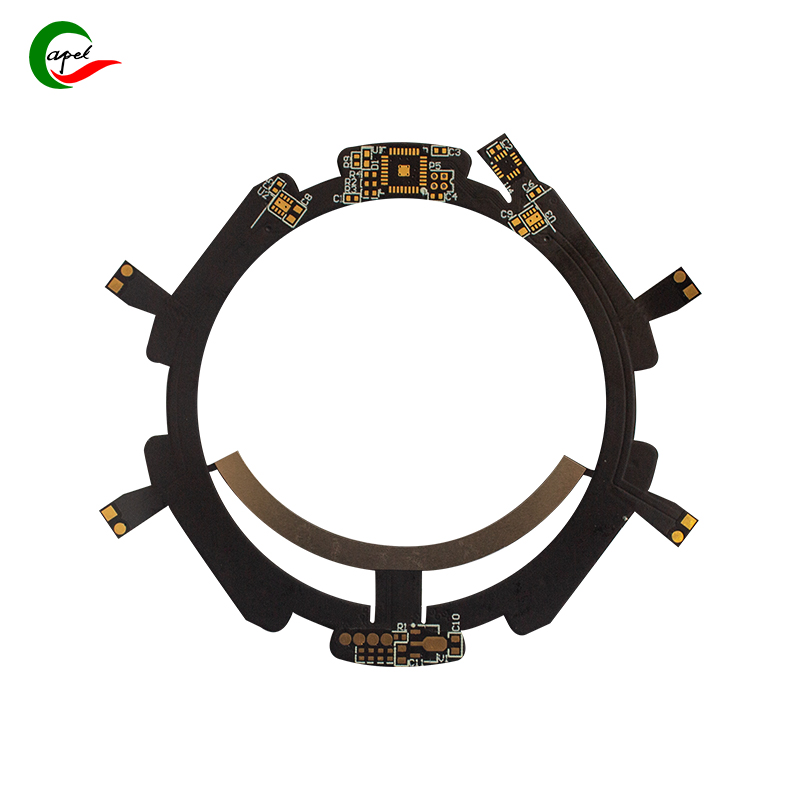

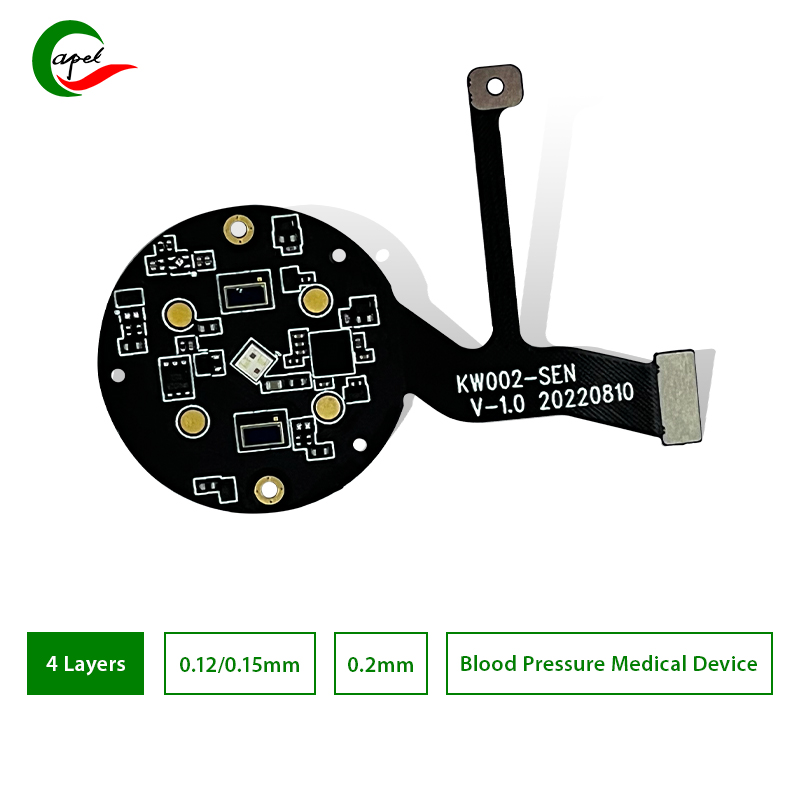

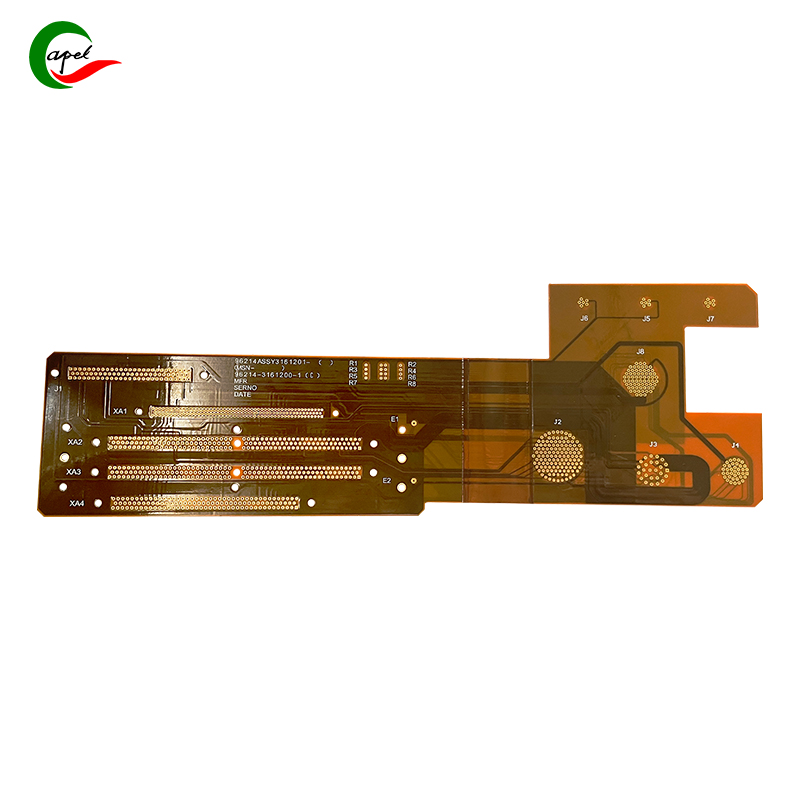

I-Capel Flexible PCB & Rigid-Flex PCB Ikhono Lenqubo

| Isigaba | Amandla okucubungula | Isigaba | Amandla okucubungula |

| Uhlobo Lokukhiqiza | I-Single layer FPC / I-Double layers FPC I-Multi-layer FPC / Aluminium PCBs I-Rigid-Flex PCB | Inombolo Yezendlalelo | 1-30Izigaba FPC 2-32izingqimba Rigid-FlexPCB1-60izingqimba I-PCB eqinile HDIAmabhodi |

| Usayizi Wokukhiqiza Omkhulu | Isendlalelo esisodwa se-FPC 4000mm Izendlalelo ezikabili FPC 1200mm Izendlalelo eziningi ze-FPC 750mm I-Rigid-Flex PCB 750mm | I-Insulating Layer Ubukhulu | 27.5um / 37.5/ 50um / 65/ 75um / 100um / 125um/150um |

| Ukujiya Kwebhodi | I-FPC 0.06mm - 0.4mm I-Rigid-Flex PCB 0.25 - 6.0mm | Ukubekezelelwa kwe-PTH Usayizi | ±0.075mm |

| I-Surface Qeda | Ukucwiliswa Igolide/Ukucwiliswa Isiliva/Igolide Plating/Tin Plating/OSP | I-Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Usayizi we-Semicircle Orifice | Ubuncane 0.4mm | Isikhala somugqa omncane/ ububanzi | 0.045mm/0.045mm |

| Ukujiya Ukubekezelelana | ±0.03mm | Impedance | 50Ω-120Ω |

| Ukuqina kwe-Copper Foil | 9um/12um/18um/35um/70um/100um | Impedance Kulawulwa Ukubekezelelana | ±10% |

| Ukubekezelelwa kwe-NPTH Usayizi | ±0.05mm | I-Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Sebenzisa Okujwayelekile | GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

I-Capel yenza ngokwezifiso ibhodi lesifunda elinembayo eliqinile eliqinile / i-Flexible PCB / HDI PCB enesipiliyoni seminyaka engu-15 ngobungcweti bethu.

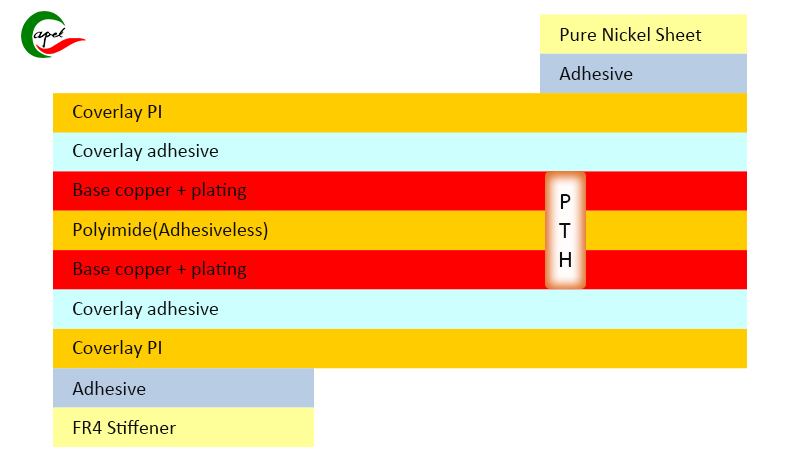

I-2 Layer Flexible PCB Boards Stackup

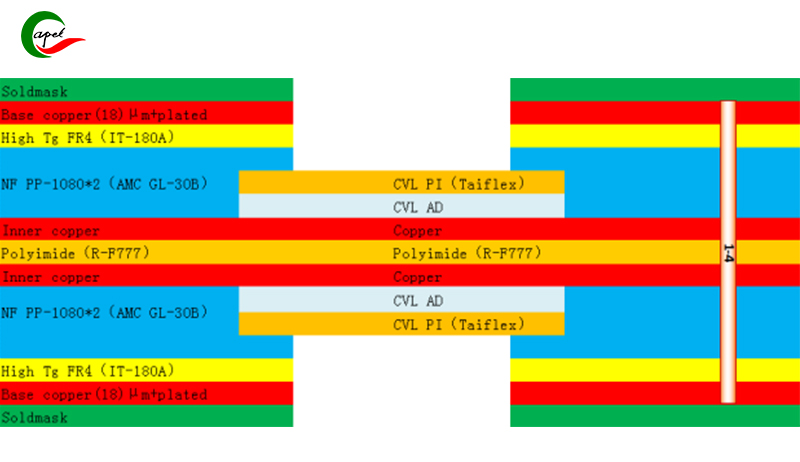

I-4 Layer Rigid-Flex PCB Stackup

8 ungqimba HDI PCBs

Izisetshenziswa zokuhlola nokuhlola

Ukuhlola Isibonakhulu

Ukuhlolwa kwe-AOI

Ukuhlolwa kwe-2D

Ukuhlolwa kwe-Impedans

Ukuhlolwa kwe-RoHS

I-Flying Probe

Umhloli Ovundlile

Ukugoba i-Teste

I-Capel inikeza amakhasimende Isevisi ye-PCB eyenziwe ngezifiso eneminyaka engu-15 yesipiliyoni

- Ubunikazi 3izimboni ze-Flexible PCB&Rigid-Flex PCB, Rigid PCB, DIP/SMT Assembly;

- 300+Onjiniyela Bahlinzeka ngosekelo lobuchwepheshe ngokuthengisa kwangaphambilini nangemuva kokuthengisa ku-inthanethi;

- 1-30izingqimba FPC,2-32izingqimba ze-Rigid-FlexPCB,1-60izingqimba I-PCB eqinile

- HDI Boards, Flexible PCB (FPC), Rigid-Flex PCBs, Multilayer PCBs, Single-sided PCB, Double-Sided Circuit Boards, Hollow Boards, Rogers PCB, rf PCB, Metal Core PCB, Special Process Boards, Ceramic PCB, Aluminium PCB , I-SMT & PTH Assembly, PCB Prototype Service.

- NikezaAmahora angu-24Isevisi ye-PCB Prototyping, Amaqoqo Amancane amabhodi wesekethe azolethwa ngaphakathiizinsuku 5-7, Ukukhiqizwa Okuningi kwamabhodi e-PCB kuzolethwa ngaphakathi2-3 amasonto;

- Izimboni esizihlinzekayo:Amadivayisi Ezokwelapha, IOT, TUT, UAV, Aviation, Automotive, Telecommunications, Consumer Electronics, Military, Aerospace, Industrial Control, Artificial Intelligence, EV, njll...

- Amandla ethu Okukhiqiza:

Umthamo wokukhiqiza we-FPC kanye ne-Rigid-Flex PCBs ungafinyelela ngaphezu kwalokho150000sqmngenyanga,

Umthamo wokukhiqiza we-PCB ungafinyelela80000sqmngenyanga,

PCB Ukuhlanganisa umthamo at150,000,000izingxenye ngenyanga.

- Amaqembu ethu onjiniyela nabacwaningi bazinikele ekugcwaliseni izidingo zakho ngokunemba nangobuchwepheshe.