Umkhiqizi we-Pcb wamabhodi weSekethe enamacala amabili

Ikhono lenqubo ye-PCB

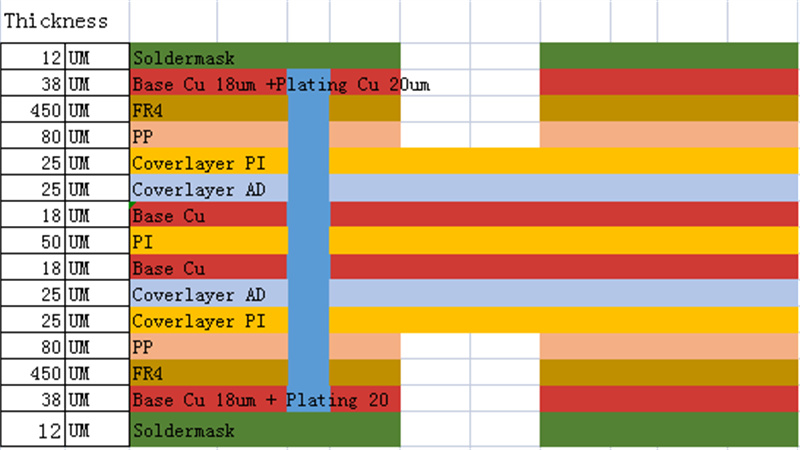

| Cha. | Iphrojekthi | Izinkomba zobuchwepheshe |

| 1 | Isendlalelo | 1-60(ungqimba) |

| 2 | Indawo yokucubungula ephezulu | 545 x 622 mm |

| 3 | Ubuncane bobukhulu | 4(ungqimba)0.40mm |

| 6(ungqimba) 0.60mm | ||

| 8(ungqimba) 0.8mm | ||

| 10(ungqimba)1.0mm | ||

| 4 | Ububanzi bomugqa obuncane | 0.0762mm |

| 5 | Isikhala esincane | 0.0762mm |

| 6 | Imbobo encane yomshini | 0.15mm |

| 7 | Imbobo yodonga lwethusi ukujiya | 0.015mm |

| 8 | Ukubekezelelwa kwe-metalized aperture | ±0.05mm |

| 9 | Ukubekezelela ukungena kwe-metallized | ±0.025mm |

| 10 | Ukubekezelelana kwezimbobo | ±0.05mm |

| 11 | Ukubekezelela Dimensional | ±0.076mm |

| 12 | Ibhuloho elincane le-solder | 0.08mm |

| 13 | Ukumelana ne-insulation | 1E+12Ω (evamile) |

| 14 | Isilinganiso sobukhulu bepuleti | 1:10 |

| 15 | Ukushaqeka okushisayo | 288 ℃ (izikhathi ezi-4 ngemizuzwana eyi-10) |

| 16 | Ihlanekezelwe futhi igobile | ≤0.7% |

| 17 | Amandla okulwa nogesi | >1.3KV/mm |

| 18 | Amandla okulwa nokuhlubula | 1.4N/mm |

| 19 | I-Solder imelana nobunzima | ≥6H |

| 20 | Ukuncipha komlilo | 94V-0 |

| 21 | Ukulawulwa kwe-impedance | ±5% |

Senza i-Circuit Boards Prototyping ngesipiliyoni seminyaka engu-15 ngobungcweti bethu

4 ungqimba Amabhodi Flex-Rigid

8 ungqimba we-Rigid-Flex PCBs

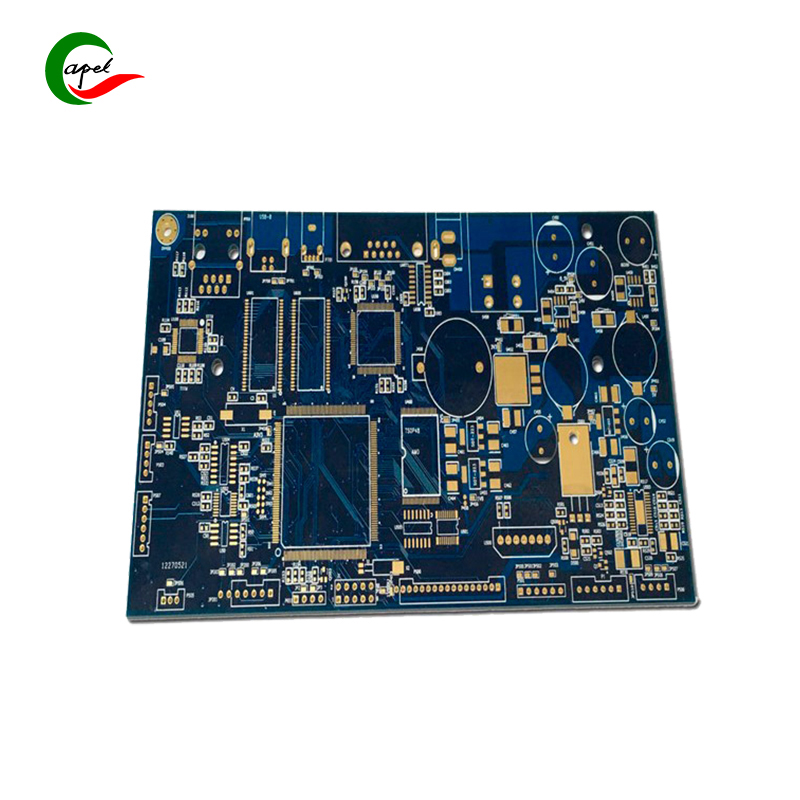

8 ungqimba HDI Amabhodi Esifunda Aphrintiwe

Izisetshenziswa zokuhlola nokuhlola

Ukuhlola Isibonakhulu

Ukuhlolwa kwe-AOI

Ukuhlolwa kwe-2D

Ukuhlolwa kwe-Impedans

Ukuhlolwa kwe-RoHS

I-Flying Probe

Umhloli Ovundlile

Ukugoba i-Teste

Isevisi Yethu Yokukopisha Yebhodi Lesifunda

. Ukuhlinzeka ngosekelo lobuchwepheshe Ukuthengisa kwangaphambili kanye nangemuva kokuthengisa;

. Yenza ngokwezifiso izendlalelo ezingafika kwezingama-40, i-1-2days ijika ngokushesha i-prototyping, ukuthengwa kwengxenye, i-SMT Assembly;

. Ibhekelela kokubili Idivayisi Yezokwelapha, Ukulawulwa Kwezimboni, Izimoto, Izindiza, I-Consumer Electronics, i-IOT, i-UAV, Ezokuxhumana njll.

. Amaqembu ethu onjiniyela nabacwaningi bazinikele ekugcwaliseni izidingo zakho ngokunemba nangobuchwepheshe.

Ungawakha kanjani amabhodi esekethe anamacala amabili aphezulu ekhwalithi ephezulu?

1. Dizayina ibhodi: Sebenzisa isofthiwe ye-computer-aid design (CAD) ukuze udale isakhiwo sebhodi. Qinisekisa ukuthi idizayini ihlangabezana nazo zonke izidingo zikagesi nezemishini, okuhlanganisa ububanzi bokulandelela, isikhala, nokubekwa kwengxenye. Cabangela izici ezifana nobuqotho besignali, ukusatshalaliswa kwamandla, nokuphathwa kokushisa.

2. I-Prototyping kanye nokuhlola: Ngaphambi kokukhiqizwa ngobuningi, kubalulekile ukwakha ibhodi le-prototype ukuze kuqinisekiswe ukuklama kanye nenqubo yokukhiqiza. Hlola kahle ama-prototypes ukuze uthole ukusebenza, ukusebenza kukagesi, nokuhambisana kwemishini ukuze uhlonze noma yiziphi izinkinga ezingaba khona noma ukuthuthukiswa.

3. Ukukhetha Okubalulekile: Khetha impahla yekhwalithi ephezulu efanelana nezidingo zakho ezithile zebhodi. Izinketho zezinto ezijwayelekile zifaka i-FR-4 noma izinga lokushisa eliphezulu i-FR-4 ye-substrate, ithusi lokulandela umkhondo, kanye nemaski ye-solder ukuvikela izingxenye.

4. Yenza ungqimba lwangaphakathi: Okokuqala lungisa ungqimba lwangaphakathi lwebhodi, olubandakanya izinyathelo ezimbalwa:

a. Hlanza futhi ugeze i-laminate ye-copper clad.

b. Gcoba ifilimu eyomile enezithombe ezincane endaweni yethusi.

c. Ifilimu ivezwa ekukhanyeni kwe-ultraviolet (UV) ngethuluzi lesithombe eliqukethe iphethini yesekethe efunekayo.

d. Ifilimu ithuthukiswa ukuze isuse izindawo ezingabonakali, ishiya iphethini yesifunda.

e. Gcoba ithusi eliveziwe ukuze ususe izinto eziningi ezisele ushiye imikhondo namaphedi kuphela.

F. Hlola ungqimba lwangaphakathi ukuze uthole noma yikuphi ukonakala noma ukuchezuka ekwakhiweni.

5. Ama-Laminates: Izendlalelo zangaphakathi zihlanganiswa ne-prepreg emshinini wokunyathelisa. Ukushisa nokucindezela kusetshenziselwa ukubopha izendlalelo futhi kwakhiwe iphaneli eqinile. Qinisekisa ukuthi izendlalelo zangaphakathi ziqondaniswe kahle futhi zibhalisiwe ukuvimbela noma yikuphi ukungahambi kahle.

6. Ukubhoboza: Sebenzisa umshini wokumba onembayo ukuze ubhoboze imbobo ukuze kufakwe ingxenye kanye nokuxhumanisa. Amasayizi ahlukene we-drill bits asetshenziswa ngokuya ngezidingo ezithile. Qinisekisa ukunemba kwendawo yembobo nobubanzi.

Ungawakha kanjani amabhodi esekethe anamacala amabili aphezulu ekhwalithi ephezulu?

7. I-Electroless Copper Plating: Faka ungqimba oluncane lwethusi kuzo zonke izindawo zangaphakathi eziveziwe. Lesi sinyathelo siqinisekisa ukuqhutshwa okufanele futhi sisiza inqubo yokucwenga ezinyathelweni ezilandelayo.

8. Ukuthwebula ungqimba lwangaphandle: Ngokufanayo nenqubo yongqimba lwangaphakathi, ifilimu eyomile ethatha izithombe imbozwa ungqimba lwethusi olungaphandle.

Iveze ekukhanyeni kwe-UV ngethuluzi lesithombe esiphezulu futhi uthuthukise ifilimu ukuze uveze iphethini yesekethe.

9. Ukushumeka koqweqwe lwangaphandle: Khipha ithusi elingadingekile kungqimba olungaphandle, ushiye imikhondo namaphedi adingekayo.

Hlola isendlalelo esingaphandle ukuze uthole noma yikuphi ukukhubazeka noma ukuchezuka.

10. I-Solder Mask kanye Nokuphrinta I-legend: Faka okokusebenza kwemaski ye-solder ukuze uvikele iminonjana yethusi namaphedi ngenkathi ushiya indawo ukuze ufakwe ingxenye. Phrinta izinganekwane nomaka phezu kwezendlalelo ezingaphezulu naphansi ukuze ubonise ingxenye yendawo, i-polarity, nolunye ulwazi.

11. Ukulungiswa komphezulu: Ukulungiswa komphezulu kusetshenziswa ukuze kuvikelwe indawo yethusi eveziwe ekufakweni kwe-oxidation futhi kunikeze indawo ethengiswayo. Izinketho zifaka i-hot air leveling (HASL), igolide lokucwiliswa kwe-nickel elingenagesi (ENIG), noma okunye ukuqedwa okuthuthukile.

12. Umzila Nokwakheka: Amaphaneli e-PCB asikwa abe amabhodi ngamanye kusetshenziswa umshini womzila noma inqubo ye-V-scribing.

Qiniseka ukuthi imiphetho ihlanzekile futhi ubukhulu bulungile.

13. Ukuhlola Ugesi: Yenza ukuhlola kukagesi njengokuhlola ukuqhubeka, izilinganiso zokumelana, nokuhlola ukuzihlukanisa ukuze uqinisekise ukusebenza nobuqotho bamabhodi akhiwe.

14. Ukulawula Ikhwalithi Nokuhlola: Amabhodi aseqediwe ahlolwa ngokucophelela ukuze abone noma yikuphi ukonakala kokukhiqiza okufana nezikhindi, ama-opens, ukungaqondani kahle, noma ukonakala kwendawo. Sebenzisa izinqubo zokulawula izinga ukuze uqinisekise ukuthotshelwa kwamakhodi namazinga.

15. Ukupakisha Nokuthumela: Ngemva kokuba ibhodi liphumelele ukuhlolwa kwekhwalithi, lipakishwa ngokuphepha ukuze livimbele ukulimala ngesikhathi sokuthunyelwa.

Qinisekisa ukulebula okufanele kanye nemibhalo ukuze ulandelele ngokunembile futhi uhlonze amabhodi.