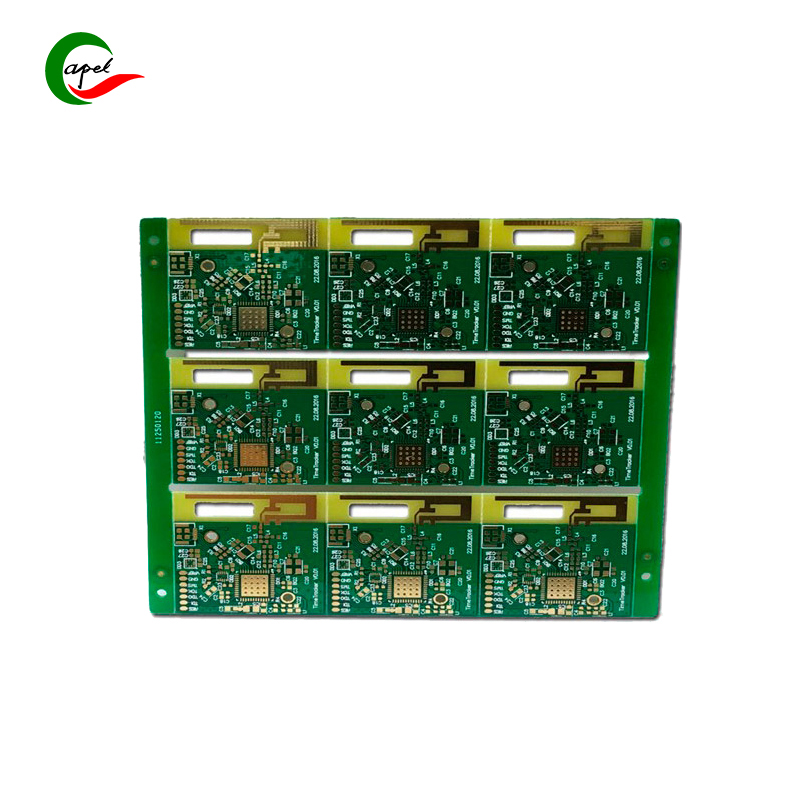

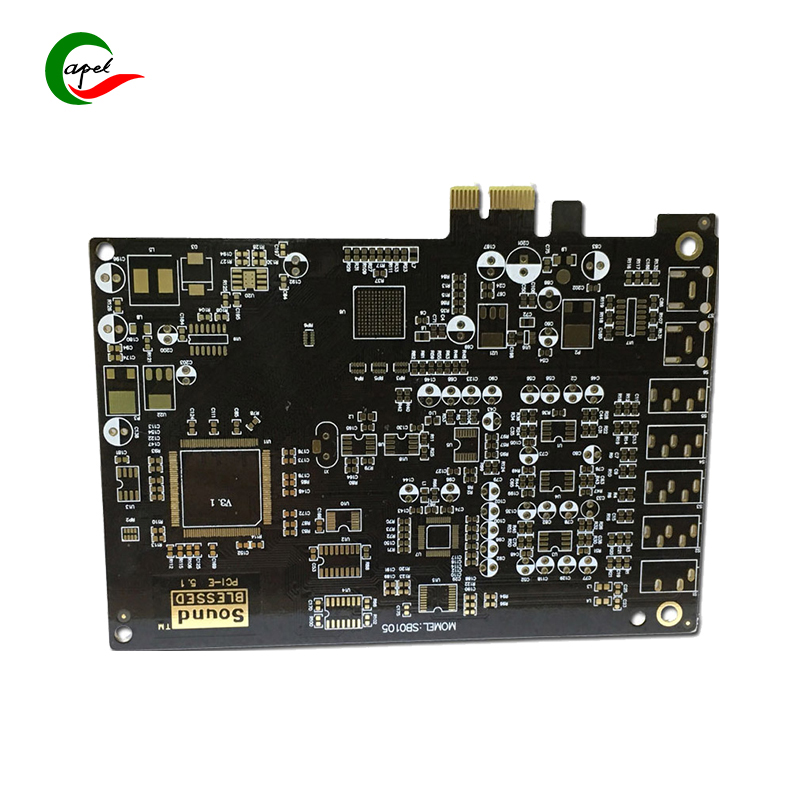

6 Layer PCB Circuit Boards Rapid Pcb Prototyping Pcb Manufacturer China

Ikhono lenqubo ye-PCB

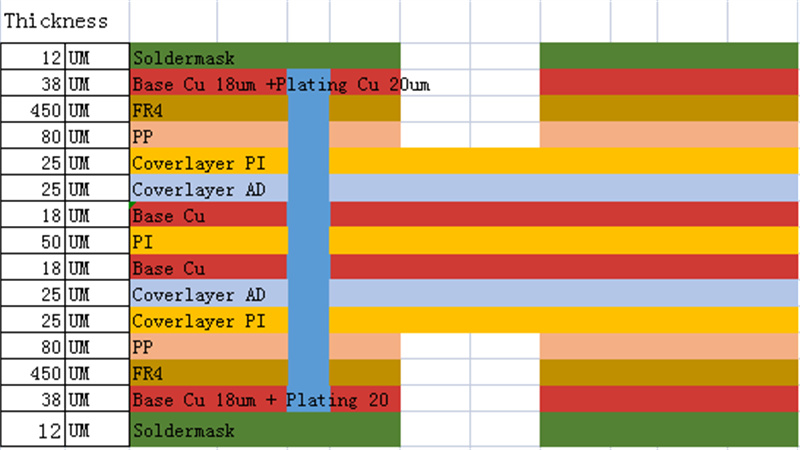

| Cha. | Iphrojekthi | Izinkomba zobuchwepheshe |

| 1 | Isendlalelo | 1-60(ungqimba) |

| 2 | Indawo yokucubungula ephezulu | 545 x 622 mm |

| 3 | Ubuncane bobukhulu | 4(ungqimba)0.40mm |

| 6(ungqimba) 0.60mm | ||

| 8(ungqimba) 0.8mm | ||

| 10(ungqimba)1.0mm | ||

| 4 | Ububanzi bomugqa obuncane | 0.0762mm |

| 5 | Isikhala esincane | 0.0762mm |

| 6 | Imbobo encane yomshini | 0.15mm |

| 7 | Imbobo yodonga lwethusi ukujiya | 0.015mm |

| 8 | Ukubekezelelwa kwe-metalized aperture | ±0.05mm |

| 9 | Ukubekezelela ukungena kwe-metallized | ±0.025mm |

| 10 | Ukubekezelelana kwezimbobo | ±0.05mm |

| 11 | Ukubekezelela Dimensional | ±0.076mm |

| 12 | Ibhuloho elincane le-solder | 0.08mm |

| 13 | Ukumelana ne-insulation | 1E+12Ω (evamile) |

| 14 | Isilinganiso sobukhulu bepuleti | 1:10 |

| 15 | Ukushaqeka okushisayo | 288 ℃ (izikhathi ezi-4 ngemizuzwana eyi-10) |

| 16 | Ihlanekezelwe futhi igobile | ≤0.7% |

| 17 | Amandla okulwa nogesi | >1.3KV/mm |

| 18 | Amandla okulwa nokuhlubula | 1.4N/mm |

| 19 | I-Solder imelana nobunzima | ≥6H |

| 20 | Ukuncipha komlilo | 94V-0 |

| 21 | Ukulawulwa kwe-impedance | ±5% |

Senza i-PCB circuit board prototype ngesipiliyoni seminyaka engu-15 ngobungcweti bethu

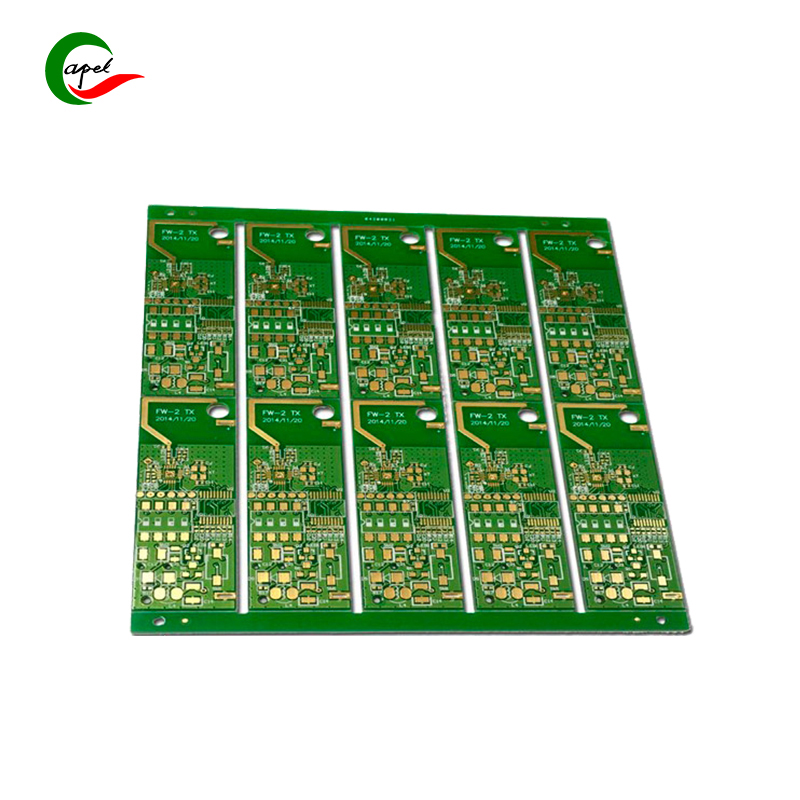

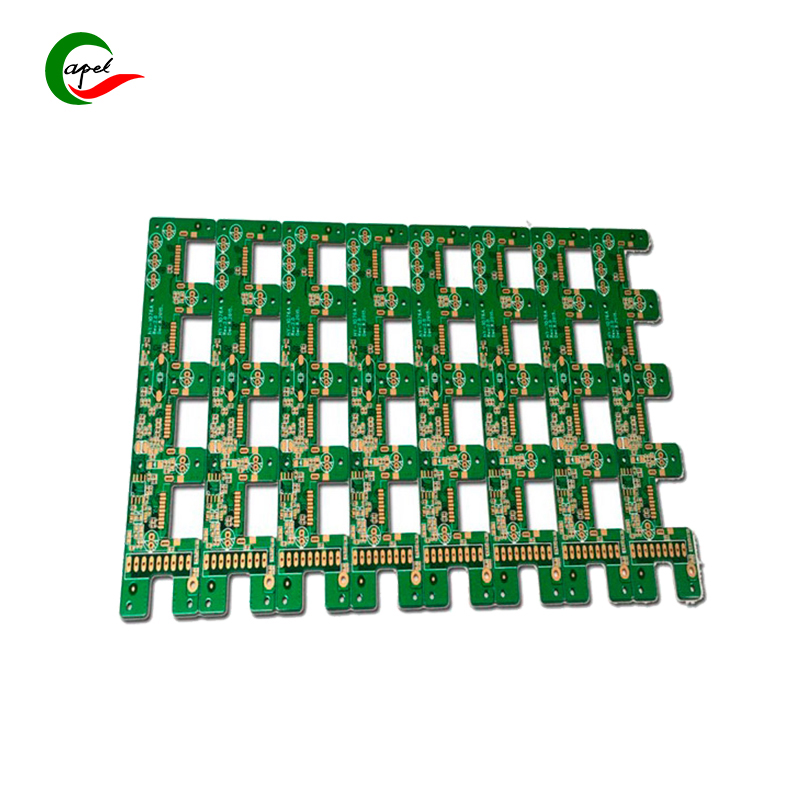

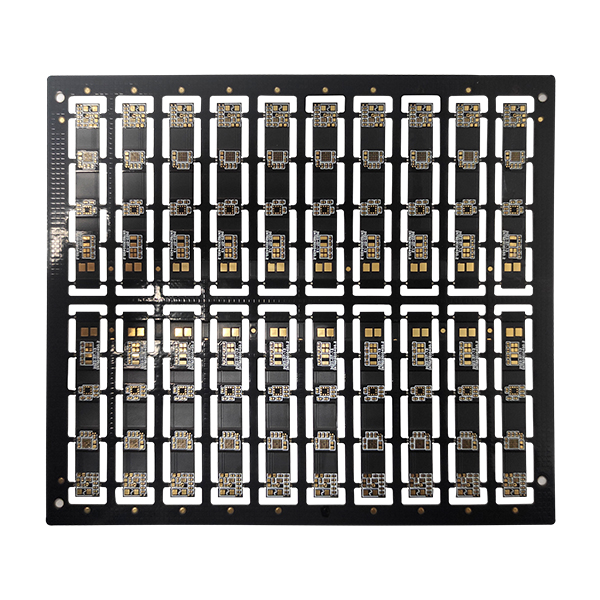

4 ungqimba Amabhodi Flex-Rigid

8 ungqimba we-Rigid-Flex PCBs

8 ungqimba HDI PCBs

Izisetshenziswa zokuhlola nokuhlola

Ukuhlola Isibonakhulu

Ukuhlolwa kwe-AOI

Ukuhlolwa kwe-2D

Ukuhlolwa kwe-Impedans

Ukuhlolwa kwe-RoHS

I-Flying Probe

Umhloli Ovundlile

Ukugoba i-Teste

PCB wethu wesifunda amabhodi prototype Service

. Ukuhlinzeka ngosekelo lobuchwepheshe Ukuthengisa kwangaphambili kanye nangemuva kokuthengisa;

. Yenza ngokwezifiso izendlalelo ezingafika kwezingama-40, i-1-2days ijika ngokushesha i-prototyping, ukuthengwa kwengxenye, i-SMT Assembly;

. Ibhekelela kokubili Idivayisi Yezokwelapha, Ukulawulwa Kwezimboni, Ezezimoto, Ezokundiza, Ezokuphepha, IOT, UAV, Ezokuxhumana njll.

. Amaqembu ethu onjiniyela nabacwaningi bazinikele ekugcwaliseni izidingo zakho ngokunemba nangobuchwepheshe.

Ungamkhetha kanjani umkhiqizi onolwazi futhi onamandla wokufakazela amabhodi wesekethe we-6-layer.

1. Bheka ukukhuluma ngomlomo nokuhlola: qonda ukuhlola kwamanye amakhasimende kanye nezwi lomlomo mayelana nomkhiqizi.

Ulwazi olubalulekile lungatholakala ngokusesha izinkundla ze-inthanethi, inkundla yezokuxhumana noma izinkundla zobuchwepheshe ukuze uthole ukubuyekezwa kanye nempendulo. Bheka labo abanegama eliqinile neminyaka yokuhlangenwe nakho.

2. Isipiliyoni nobungcweti: Qiniseka ukuthi umenzi unesipiliyoni esicebile kanye nekhono ekwenzeni amabhodi esekethe anezendlalelo eziyisi-6.

Funda ngomlando wabo nesizinda sabo, okuhlanganisa ukuthi banesikhathi esingakanani besembonini kanye nenani lamaphrojekthi abawaqedile.

3. Amakhono ezobuchwepheshe nezinto zokusebenza: Hlola ukuthi umakhi unazo yini izinto ezithuthukisiwe nobuchwepheshe bokwenza amabhodi esekethe anezendlalelo eziyisi-6.

Funda ngamakhono abo okwenza amabhodi ayinkimbinkimbi kanye nama-high density assemblies ukuze uqiniseke ukuthi angakwazi ukuhlangabezana nezidingo zakho.

4. Ukulawulwa kwekhwalithi: Qonda uhlelo lokulawula ikhwalithi lomkhiqizi kanye nenqubo. Ingabe banamazinga aqinile okulawula ikhwalithi nezinto zokuhlola ezifanele ukuze kuqinisekiswe ikhwalithi yomkhiqizo, njengokuthi bayalusebenzisa yini uhlelo lokuphatha ikhwalithi lwe-ISO 9001.

5. Ukwethembeka kanye nokulethwa: Hlola ukwethembeka nokulethwa komphakeli. Ingabe bayakwazi ukuqeda amaphrojekthi ngesikhathi futhi banikeze izikhathi zokulethwa ezinembile. Buza ukuthi banalo yini uhlelo lokusekelayo oluphuthumayo uma kwenzeka ukubambezeleka noma izehlakalo ezingalindelekile.

6. Khuluma namakhasimende akhona: Uma kungenzeka, khuluma namakhasimende akhona omphakeli. Funda mayelana nolwazi lwabo lokubambisana nokwaneliseka, kanye nesimo sengqondo sokusebenza komenzi kanye nesivinini sokuphendula.

7. Ingxoxo noma xhumana nabakhiqizi: yenza izingxoxo noma uxhumane nabangase bakhiqize, futhi ubabuze mayelana nezidingo zokuqinisekisa kanye nezidingo zobuchwepheshe. Bheka ukuthi izimpendulo nezincazelo zabo zinembile, ziwuchwepheshe, futhi ziyanelisa yini, ukuze wahlulele ukuthi banalo yini ulwazi namandla owadingayo.

8. Intengo nesevisi: Okokugcina, cabangela inani kanye nesevisi yangemuva kokuthengisa ngokugcwele. Qiniseka ukuthi intengo inengqondo futhi inikeza ukusekelwa okufanele ngemva kokuthengisa, njengokubonisana nobuchwepheshe, ukulandelela ukukhiqiza nokuxazulula izinkinga, njll.

Inqubo yokuhlola ye-6 layer PCB amabhodi wesifunda

1. Dizayina umdwebo wohlelo lwesekethe nesakhiwo: okokuqala dweba umdwebo wohlelo lwesekethe kanye nesakhiwo ngokuya ngezidingo zokuklama isekethe. Lesi isinyathelo esibalulekile ekunqumeni ubukhulu bebhodi, imithetho yemizila, ukubekwa kwedivayisi, nokuningi.

2. Yenza amafayela ebhodi lesifunda: Sebenzisa isofthiwe yokuklama ye-PCB ukuze uguqule izinhlelo zesifunda nezakhiwo zibe amafayela ebhodi lesifunda.

Lawa mafayela ngokuvamile ahlanganisa amafayela e-Gerber, amafayela wokubhoboza, amafayela we-soldermask, njll.

3. Qinisekisa ukuklama: Ngaphambi kokuba ibhodi lesifunda likhiqizwe, umklamo wesifunda uyaqinisekiswa. Qinisekisa ukuthi idizayini yakho yebhodi ayinawo amaphutha nezinkinga zokwenziwa ngokwenza ukulingisa kwesekethe kanye nokuhlaziya i-DFM (Design for Manufacturability).

4. Thumela i-oda: Thumela imibhalo yebhodi kanye nezidingo zokukhiqiza ezihambisanayo kumkhiqizi webhodi. Ngokuvamile kudingekile ukuhlinzeka ngefomethi yefayela, impahla yebhodi lesifunda, inani lezendlalelo, izidingo zephedi, umbala wemaski we-solder, izidingo zesikrini sikasilika, izidingo zenqubo, njll.

5. Ukukhiqiza ibhodi lesifunda: Umkhiqizi webhodi lesifunda ukhiqiza ngokuvumelana nemibhalo enikeziwe.

Lokhu kuhlanganisa ukusebenzisa amafilimu amancanyana ukuze udale amaphethini webhodi lesifunda aphrintiwe, ukufakwa kwamakhemikhali noma ukwenza imishini ukuze kukhishwe izendlalelo zethusi ezingafuneki, ukubhoboza, i-copper plating, ukumbondelana (amaphedi, i-soldermask, isikrini sesilika), ukudayela nezinye izinqubo.

6. Yenza ukuhlolwa kokusebenza: Yenza ukuhlolwa kokusebenza ebhodini elilodwa elakhiwe ukuze uqinisekise ukusebenza kwalo okuvamile.

7. Hlanganisa ibhodi lesifunda: faka ibhodi lesifunda emishinini ehambisanayo ukuze uthole ukuhlolwa okusebenzayo noma ukusetshenziswa okusebenzayo.

8. Hlola imiphumela yokuhlola: Ngemva kokuthola ibhodi lesifunda lokuhlola, yenza ukuhlola okuphelele.

Hlola ukuthi ukubukeka nobukhulu bebhodi lesifunda kuyahlangabezana yini nezidingo, hlola iphedi nekhwalithi yokushisela, futhi uhlole ukuthi ukusebenza nokusebenza kwebhodi lesifunda kujwayelekile.

9. Ukuguqulwa kanye nokwenza kahle: Yenza ukuguqulwa okudingekayo kanye nokwenza kahle ngokwemiphumela yokuhlola.

Uma ibhodi lesifunda litholakala linezinkinga noma lidinga ukuthuthukiswa, amafayela okuklama angashintshwa ngokufanele.

10. Ukuqinisekisa kabusha: Uma ibhodi lesifunda linenani elikhulu lokuguqulwa noma ukuphindaphinda okuningi okudingekayo, ukuqinisekiswa kabusha kungenziwa.

Phinda inqubo yangaphambilini, hambisa ifayela efekthri ukuze likhiqize futhi, bese uhlola bese ubuyekeza futhi.

11. Ukukhiqizwa okukhulu: Uma ukuklama nokusebenza kwebhodi lesifunda kuyanelisa, ukukhiqizwa ngobuningi kungenziwa. Abakhiqizi bakhiqiza ngokuvumelana namafayela wokugcina wokuklama, futhi bakhiqize inqwaba yamabhodi wesifunda ukuze banikeze amakhasimende.

12. Landelela futhi ulawule i-supply chain: Kubaluleke kakhulu ukulandelela nokuphatha uchungechunge lokuhlinzeka ngesikhathi sokuhlola kanye nenqubo yokukhiqiza ngobuningi.

Qinisekisa ukuhlinzekwa kwezinto zokwakha, ubuyekeze ngesikhathi inqubekelaphambili yokukhiqiza, amalungiselelo okusebenza, njll., futhi uqinisekise ukulethwa ngesikhathi kwamabhodi esekethe.