6 Ungqimba HDI PCB FR4 Circuit Boards Pcb Gold Fingers

Ikhono lenqubo ye-PCB

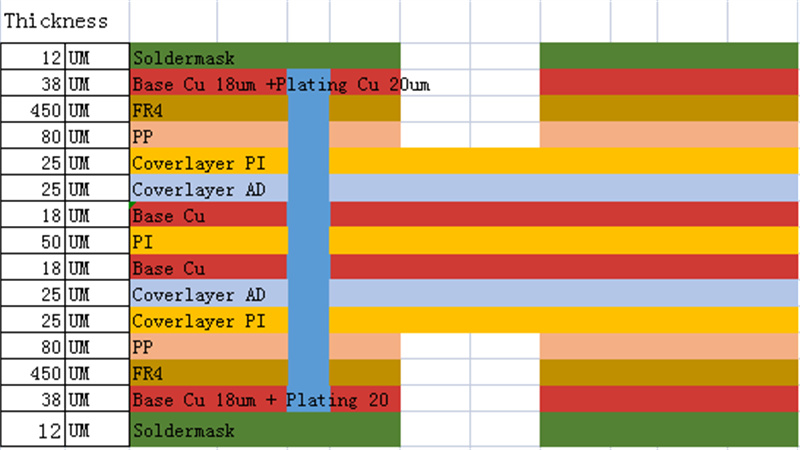

| Cha. | Iphrojekthi | Izinkomba zobuchwepheshe |

| 1 | Isendlalelo | 1-60(ungqimba) |

| 2 | Indawo yokucubungula ephezulu | 545 x 622 mm |

| 3 | Ubuncane bobukhulu | 4(ungqimba)0.40mm |

| 6(ungqimba) 0.60mm | ||

| 8(ungqimba) 0.8mm | ||

| 10(ungqimba)1.0mm | ||

| 4 | Ububanzi bomugqa obuncane | 0.0762mm |

| 5 | Isikhala esincane | 0.0762mm |

| 6 | Imbobo encane yomshini | 0.15mm |

| 7 | Imbobo yodonga lwethusi ukujiya | 0.015mm |

| 8 | Ukubekezelelwa kwe-metalized aperture | ±0.05mm |

| 9 | Ukubekezelela ukungena kwe-metallized | ±0.025mm |

| 10 | Ukubekezelelana kwezimbobo | ±0.05mm |

| 11 | Ukubekezelela Dimensional | ±0.076mm |

| 12 | Ibhuloho elincane le-solder | 0.08mm |

| 13 | Ukumelana ne-insulation | 1E+12Ω (evamile) |

| 14 | Isilinganiso sobukhulu bepuleti | 1:10 |

| 15 | Ukushaqeka okushisayo | 288 ℃ (izikhathi ezi-4 ngemizuzwana eyi-10) |

| 16 | Ihlanekezelwe futhi igobile | ≤0.7% |

| 17 | Amandla okulwa nogesi | >1.3KV/mm |

| 18 | Amandla okulwa nokuhlubula | 1.4N/mm |

| 19 | I-Solder imelana nobunzima | ≥6H |

| 20 | Ukuncipha komlilo | 94V-0 |

| 21 | Ukulawulwa kwe-impedance | ±5% |

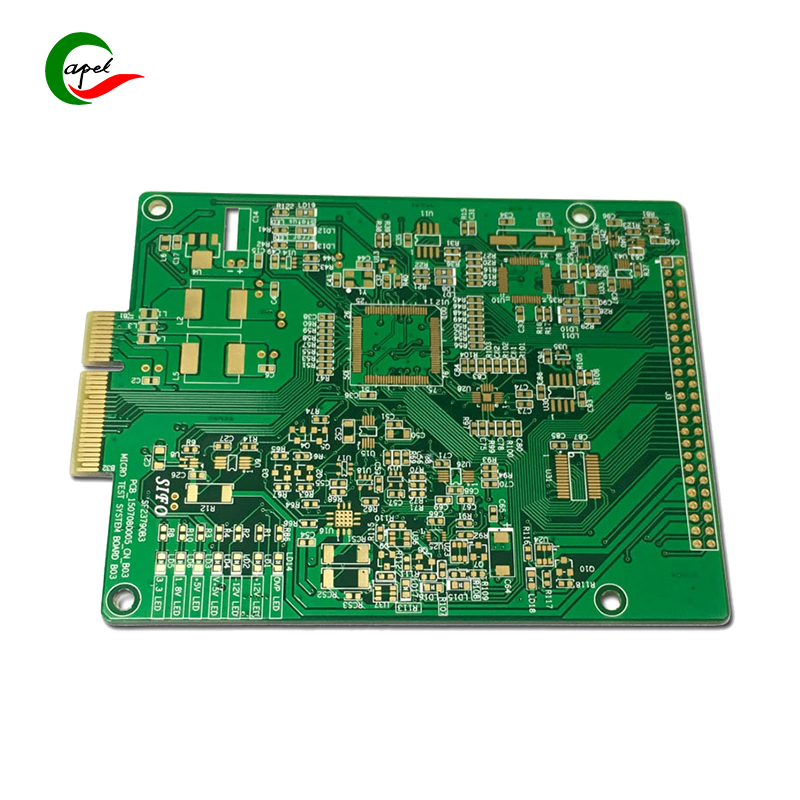

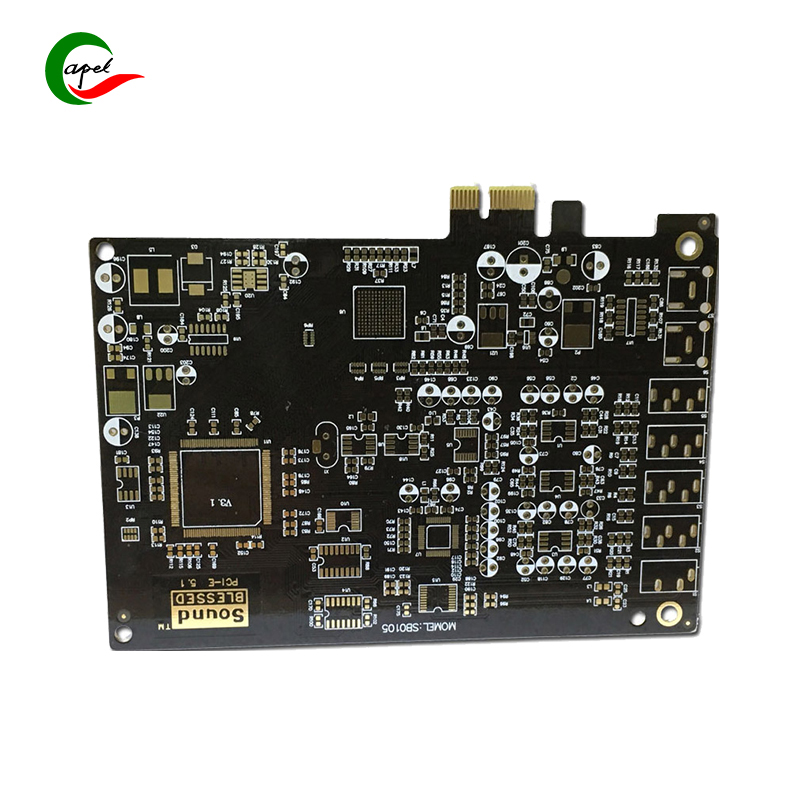

Senza 6 layer HDI PCB ngesipiliyoni seminyaka engu-15 ngobuchwepheshe bethu

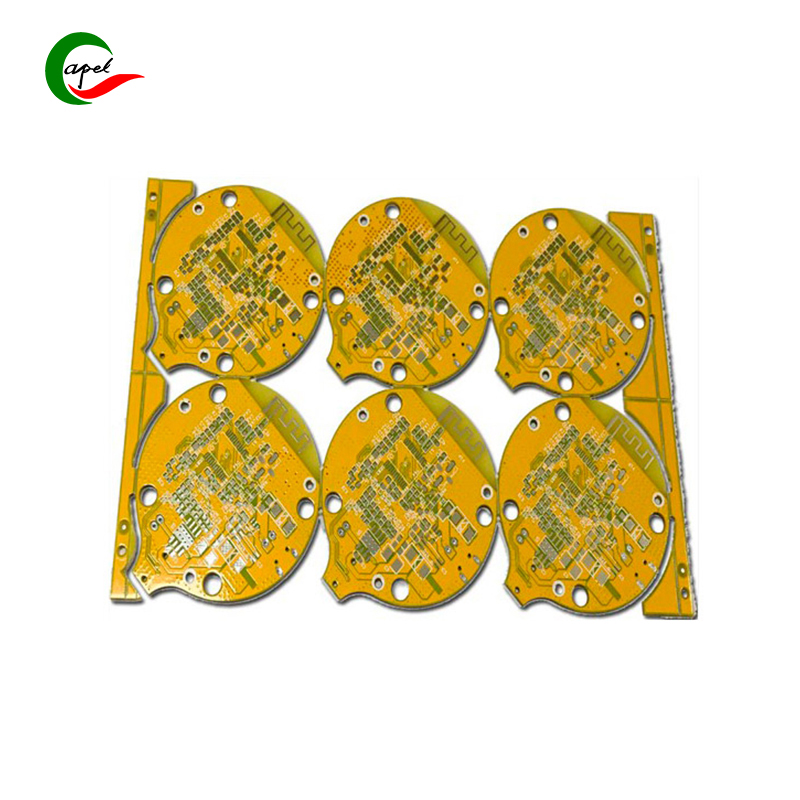

4 ungqimba Amabhodi Flex-Rigid

8 ungqimba we-Rigid-Flex PCBs

8 ungqimba HDI Amabhodi Esifunda Aphrintiwe

Izisetshenziswa zokuhlola nokuhlola

Ukuhlola Isibonakhulu

Ukuhlolwa kwe-AOI

Ukuhlolwa kwe-2D

Ukuhlolwa kwe-Impedans

Ukuhlolwa kwe-RoHS

I-Flying Probe

Umhloli Ovundlile

Ukugoba i-Teste

Isevisi yethu ye-HDI PCB engu-6 layer

. Ukuhlinzeka ngosekelo lobuchwepheshe Ukuthengisa kwangaphambili kanye nangemuva kokuthengisa;

. Yenza ngokwezifiso izendlalelo ezingafika kwezingama-40, i-1-2days ijika ngokushesha i-prototyping, ukuthengwa kwengxenye, i-SMT Assembly;

. Ibhekelela kokubili Idivayisi Yezokwelapha, Ukulawulwa Kwezimboni, Izimoto, Izindiza, I-Consumer Electronics, i-IOT, i-UAV, Ezokuxhumana njll.

. Amaqembu ethu onjiniyela nabacwaningi bazinikele ekugcwaliseni izidingo zakho ngokunemba nangobuchwepheshe.

Uhlelo lokusebenza olukhethekile lwe-HDI PCB lwe-6 ku-Automotive

1. I-ADAS (I-Advanced Driver Assistance System): Amasistimu e-ADAS athembele kuzinzwa eziningi ezifana namakhamera, ama-radar, nama-lidar ukusiza abashayeli ekuzulazuleni nasekugwemeni ukungqubuzana. I-HDI PCB enezingqimba ezi-6 isetshenziswa kumamojula e-ADAS ukuze afake uxhumo lwenzwa yokuminyana okuphezulu nokuqinisekisa ukudluliswa kwesignali okuthembekile ukuze kutholwe into enembile kanye nesexwayiso somshayeli.

2. Uhlelo lwe-Infotainment: Uhlelo lwe-infotainment ezimotweni zesimanje luhlanganisa imisebenzi ehlukahlukene njengokuzulazula kwe-GPS, ukudlalwa kwe-multimedia, izinketho zokuxhuma kanye nezindawo zokuxhumana. I-HDI PCB enezingqimba ezi-6 inika amandla ukuhlanganiswa okuhlangene kwezingxenye, izixhumi nezindawo zokusebenzelana, iqinisekisa ukuxhumana okuphumelelayo, ukulawula okuthembekile kanye nolwazi oluthuthukisiwe lomsebenzisi.

3. Iyunithi Yokulawula Injini (ECU): Iyunithi yokulawula injini inesibopho sokuqapha nokulawula imisebenzi yenjini ehlukahlukene njengokujova uphethiloli, isikhathi sokubasa, nokulawula ukungcola. I-HDI PCB enezingqimba eziyisi-6 isiza ukufaka ukujikeleza okuyinkimbinkimbi kanye nokuxhumana kwesivinini esikhulu phakathi kwezinzwa zenjini ezahlukene nama-actuator, iqinisekisa ukulawula kwenjini okunembayo nokusebenza kahle.

4. I-Electronic Stability Control (ESC): Uhlelo lwe-ESC luthuthukisa ukuzinza nokuphepha kwemoto ngokuqhubeka nokuqapha nokulungisa ukubhuleka kwesondo ngalinye kanye ne-torque yenjini. I-6-layer HDI PCB idlala indima ebalulekile kumojula ye-ESC, yenza kube lula ukuhlanganiswa kwama-microcontrollers, izinzwa, nama-actuator ukuze kuhlaziywe idatha yesikhathi sangempela nokulawula okunembile.

5. I-Powertrain: I-Powertrain Control Unit (PCU) ilawula ukusebenza kwenjini, ukuhanjiswa kanye ne-drivetrain ukuze isebenze kahle nokusebenza kahle. I-HDI PCB enezingqimba ezi-6 ihlanganisa izingxenye ezihlukahlukene zokuphatha amandla, izinzwa zokushisa nezindawo zokuxhumana, iqinisekisa ukudluliswa kwamandla okuphumelelayo, ukushintshaniswa kwedatha okuthembekile nokuphathwa okushisayo okusebenzayo.

6. Uhlelo Lokuphatha Ibhethri (BMS): I-BMS inesibopho sokuqapha nokulawula ukusebenza, ukushaja nokuvikela ibhethri lemoto. I-HDI PCB enezingqimba ezi-6 inika amandla ukwakheka okuhlangene nokuhlanganiswa kwezingxenye ze-BMS, okuhlanganisa ama-IC okuqapha ibhethri, izinzwa zokushisa, izinzwa zamanje, nezindawo zokuxhumana, iqinisekisa ukuphathwa kwebhethri okunembile kanye nokwelula impilo yebhethri.

I-6 layer HDI PCB ithuthukisa kanjani ubuchwepheshe ku-Automotive?

1. I-Miniaturization: I-6-layer HDI PCB ivumela ukubekwa kwengxenye ephezulu yokuminyana, ngaleyo ndlela ibona ukuncishiswa okuncane kwamasistimu kagesi. Lokhu kubalulekile embonini yezimoto lapho isikhala ngokuvamile silinganiselwe. Ngokunciphisa usayizi we-PCB, abakhiqizi bangaklama izimoto ezincane, ezilula futhi ezihlangene.

2. Thuthukisa ubuqotho besignali: Ubuchwepheshe be-HDI bunciphisa ubude bokulandelela isignali futhi bunikeze ukulawula okungcono kwe-impedance.

Lokhu kuthuthukisa ikhwalithi yesignali, kunciphisa umsindo futhi kuthuthukisa ubuqotho besignali. Ukuqinisekisa ukusebenza kwesignali okuthembekile kubalulekile ezinhlelweni zezimoto lapho ukudluliswa kwedatha nokuxhumana kubalulekile.

3. Ukusebenza okuthuthukisiwe: Izendlalelo ezengeziwe ku-HDI PCB enezingqimba ezi-6 zinikeza isikhala esiningi somzila kanye nezinketho zokuxhumanisa, zivumela ukusebenza okuthuthukisiwe. Izimoto manje zihlanganisa imisebenzi ye-elekthronikhi ehlukahlukene, efana nesistimu yokusiza abashayeli (ADAS), amasistimu we-infotainment namayunithi okulawula injini. Ukusetshenziswa kwe-6-layer HDI PCB kusiza ukuhlanganiswa kwale misebenzi eyinkimbinkimbi.

4. Ukudluliswa kwedatha ngesivinini esikhulu: Amasistimu ezimoto, njengamasistimu okuzulazula athuthukile kanye nokuxhumana phakathi kwezimoto, adinga ukudluliswa kwedatha ngesivinini esikhulu. I-HDI PCB enezingqimba eziyisi-6 isekela izinhlelo zokusebenza zefrikhwensi ephezulu yokudluliswa kwedatha okusheshayo nangempumelelo kakhudlwana. Lokhu kubalulekile ekuthathweni kwezinqumo ngesikhathi sangempela, ukuthuthukisa ukuphepha nokusebenza.

5. Ukuthembeka okuthuthukisiwe: Ubuchwepheshe be-HDI busebenzisa i-micro-vias ukuze buhlinzeke ngoxhumo olungcono kagesi kuyilapho kuthatha indawo encane.

Lezi zindlela ezincane zisiza ukuthuthukisa ukwethembeka ngokunciphisa ingcuphe ye-signal crosstalk kanye nokungahambisani kahle kwe-impedance. Kogesi wezimoto lapho ukuthembeka kubaluleke kakhulu, ama-HDI PCB aqinisekisa ukuxhumana okuqinile nokuqina.

6. Ukuphathwa kokushisa: Ngokukhula kobunzima kanye nokusetshenziswa kwamandla kagesi wezimoto, ukuphathwa okushisayo okusebenzayo kubalulekile. I-HDI PCB enezingqimba ezi-6 isekela ukuqaliswa kwe-thermal vias ukusiza ukuqeda ukushisa nokulawula izinga lokushisa.

Lokhu kuvumela amasistimu ezimoto ukuthi asebenze kahle, ngisho nasemazingeni okushisa aphezulu.